Costacurta’s Separation Technologies area has been committed to developing solutions that best meet its clients’ gas-liquid and liquid-liquid separation needs for more than 60 years.

Do you have a specific request?

Contact us nowOur engineering capabilities and wide range of separator internals are the result of a continuous learning process and of a strong commitment to engineering and product development.

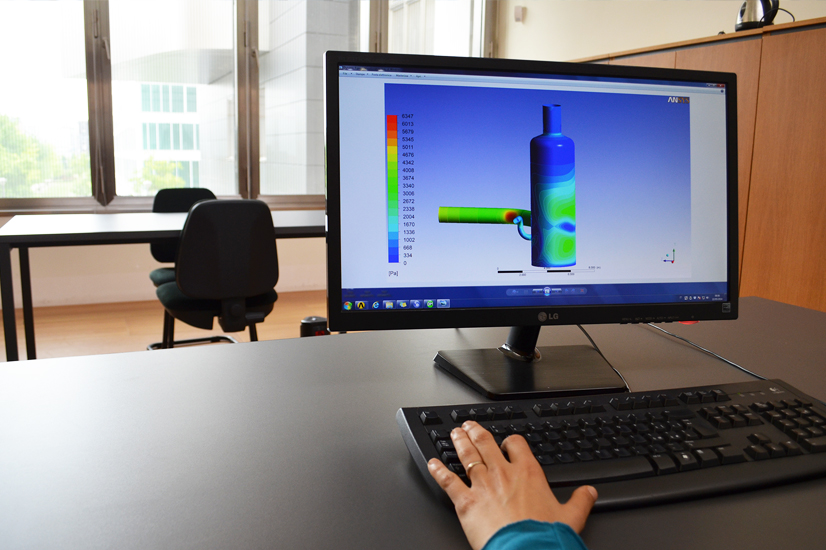

The tools we use today in our Separation Technologies area include Computational Fluid Dynamics (CFD), Finite Element Analysis, process design tools developed in-house, 2D and 3D modelling as well as an internal testing facility. These tools enable us to further develop our technology and to deliver high quality products, solutions and services.

How we work

Depending on the operating conditions (temperature and pressure) and properties of the process fluids (flow rate, density, viscosity and surface tension), Costacurta selects and designs the best internals with the aim of achieving the required performance, minimising pressure drop, weights, dimension and costs of the internals and of the separators they are installed in.

Guaranteed performance

Revamping

In the case of the revamping of existing equipment, Costacurta selects and designs separator internals, sometimes also making one-off components designed for a specific application, able to guarantee the required separation performance without having to replace the pressure vessel. We also design and supply special systems to support the internals that minimise or eliminate the need for the welding of the pressurised parts.

New projects

In the case of new projects or plants, Costacurta’s Separation Technologies department is able to dimension the vessels, optimising their size. In these cases, along with the construction drawings of the internals, information is also provided about the vessel’s dimensions and layout as well as the dimensions and thickness of the supports to weld to the tank’s walls.

Distinctive elements of Costacurta’s Separation Technologies area

Over 60 years’ experience in separation technologies

Engineering department dedicated to process engineering and CFD analysis

High quality of the product and detailed process engineering

Tools

CFD

Computational Fluid Dynamics is the numerical solution of the Navier Stokes equations for single-phase and multiphase flows. It simulates the behaviour of gas and liquid phase fluids in equipment. It is therefore useful in optimising the design of separators and in performing studies for the development of new equipment, significantly reducing the number of tests required.

FEA

Finite Element Analysis is the numerical solution of a system of partial differential equations that allows calculation of stresses and deformations on bodies subject to external and internal loads. Combined with CFD, it allows optimisation of mechanical, fluid-dynamic and process design.

Process engineering

Procedures and calculation software developed in-house for the dimensioning of separators with the related internals. These tools enable us to identify the set of internals that best meets specific needs.

2D and 3D design

2D and 3D modelling contributes to optimising the geometries of separators and their relative internals. It is also useful for checking the feasibility of modifications to existing equipment, with the aim of reducing or avoiding the welding of parts under pressure.

Test facility

The equipment at our testing facility, that includes measuring and recording tools, monitors the efficiency and the pressure drop of the separator internals in order to develop new products or improve the performance and calculation procedures of those already in production.

Applications

Ammonia conversion

Natural Gas Treatment

Power Generation

Water and Waste Treatment

Chemical

Refining