Costacurta’s long-standing experience in this sector means it can design, manufacture and supply ideal separation solutions in the oil and gas production.

More specifically, the company designs and manufactures internals for gas-liquid-liquid and liquid-liquid separators.

The production of oil and gas includes all the processes of phase separation, waste water treatment, first treatment and pumping or compression of liquid and gaseous hydrocarbons extracted from the respective oilfields, and final reinjection of gas or water into the oilfields. Plants are normally located close to extraction sites and can therefore be located onshore or offshore. In the latter case they can be located either on fixed or floating platforms or on ships (FPSOs).

Different separators can be used in phase separation, such as ‘test separators’, ‘production separators’, ‘free water ko drums’, ‘oil coalescers’, ‘flare ko drums,’ with different configurations and types of gas-liquid or liquid-liquid internals.

Costacurta’s team of process engineers choose and design the correct set of internals based on the operating conditions (temperature and pressure) and the process fluids’ properties (flow rate, density, viscosity and surface tension). The aim is to guarantee efficiency and minimise pressure drops, weights, dimensions and cost of the internals and separators they are installed in.

Do you have a specific request?

Contact us now

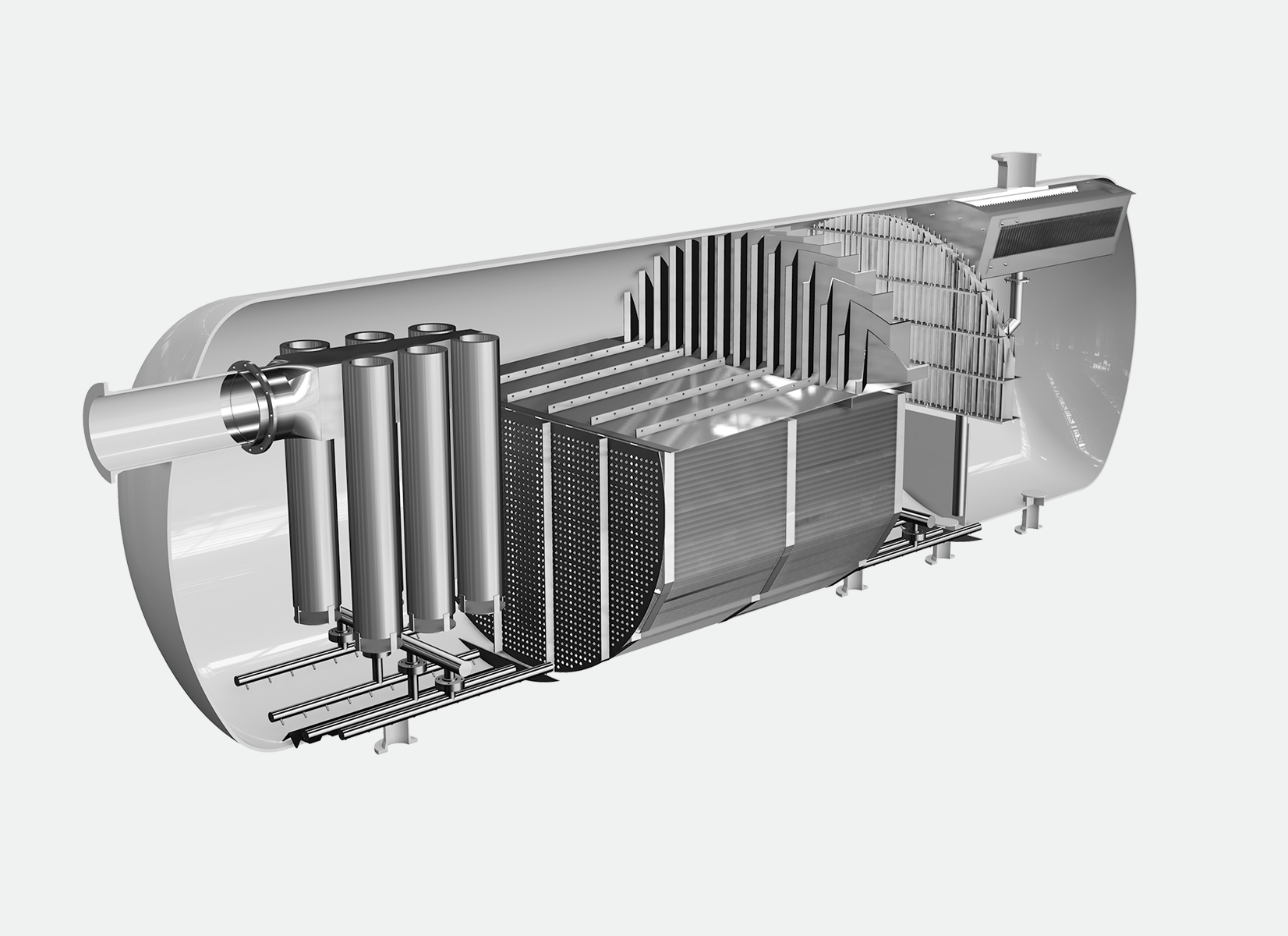

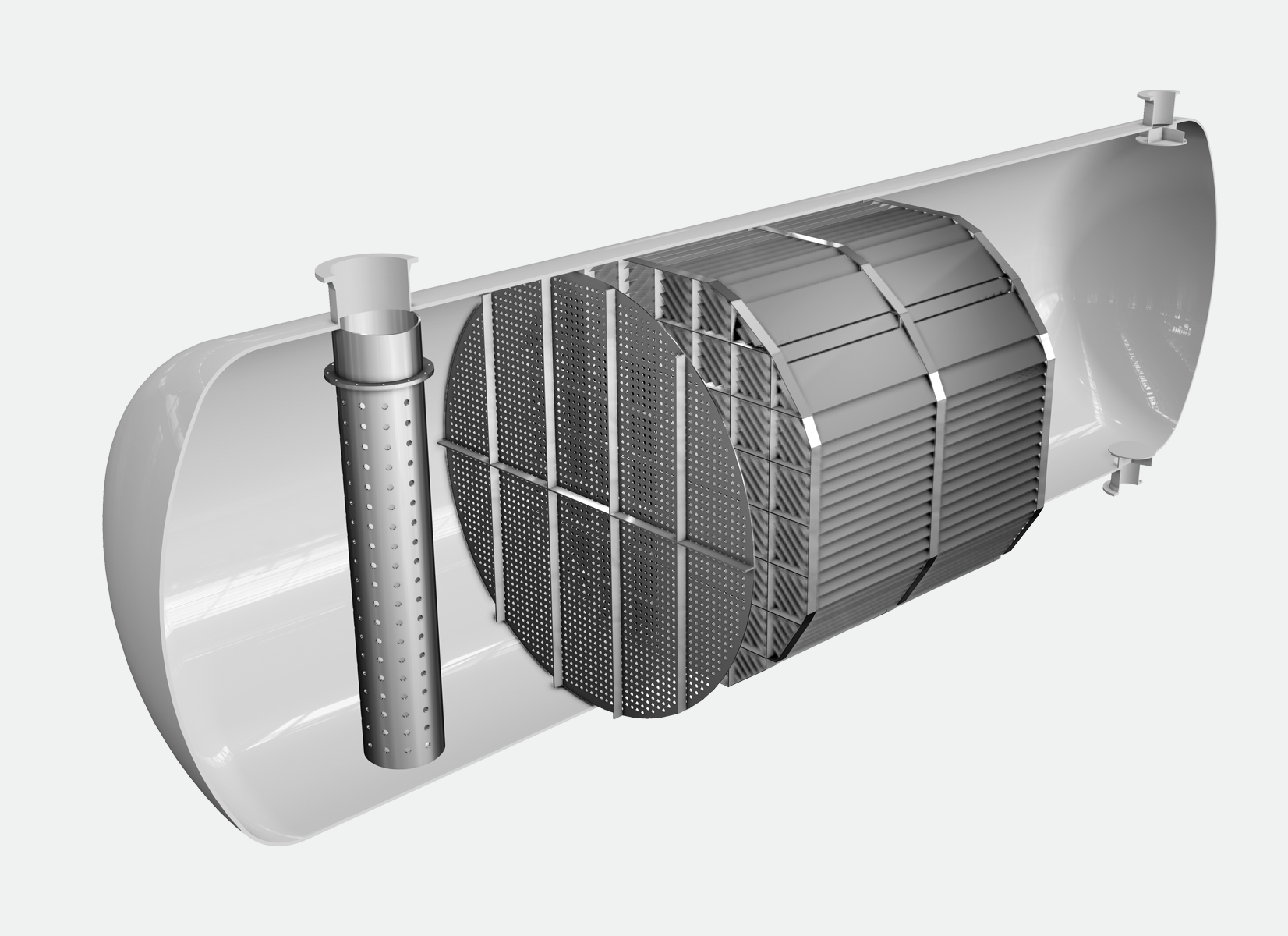

Horizontal gas-liquid-liquid separator

Typical horizontal gas-liquid-liquid separator fitted with cyclonic inlet distributor, perforated plate calming baffle, VICO-Pack, anti-turbulence slats, VICO-Straightener, VICO-Vane droplet separator and sand jetting system. Horizontal gas-liquid-liquid separators with this combination of internals are widely used when gas and liquid loads are high and separation of liquid-liquid primary dispersions is required. They are the ideal solution for offshore and FPSO applications and for the retrofitting of existing equipment.

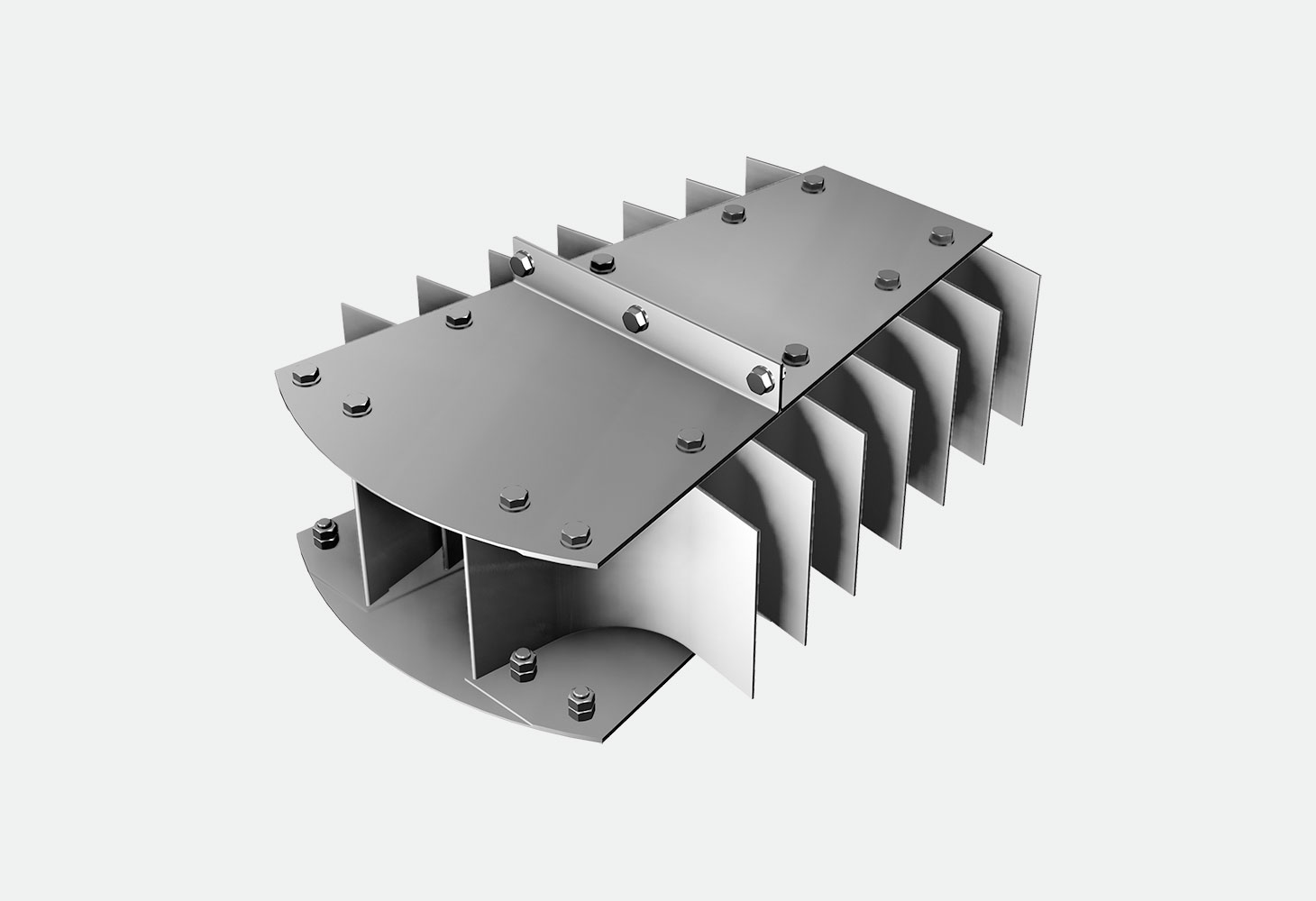

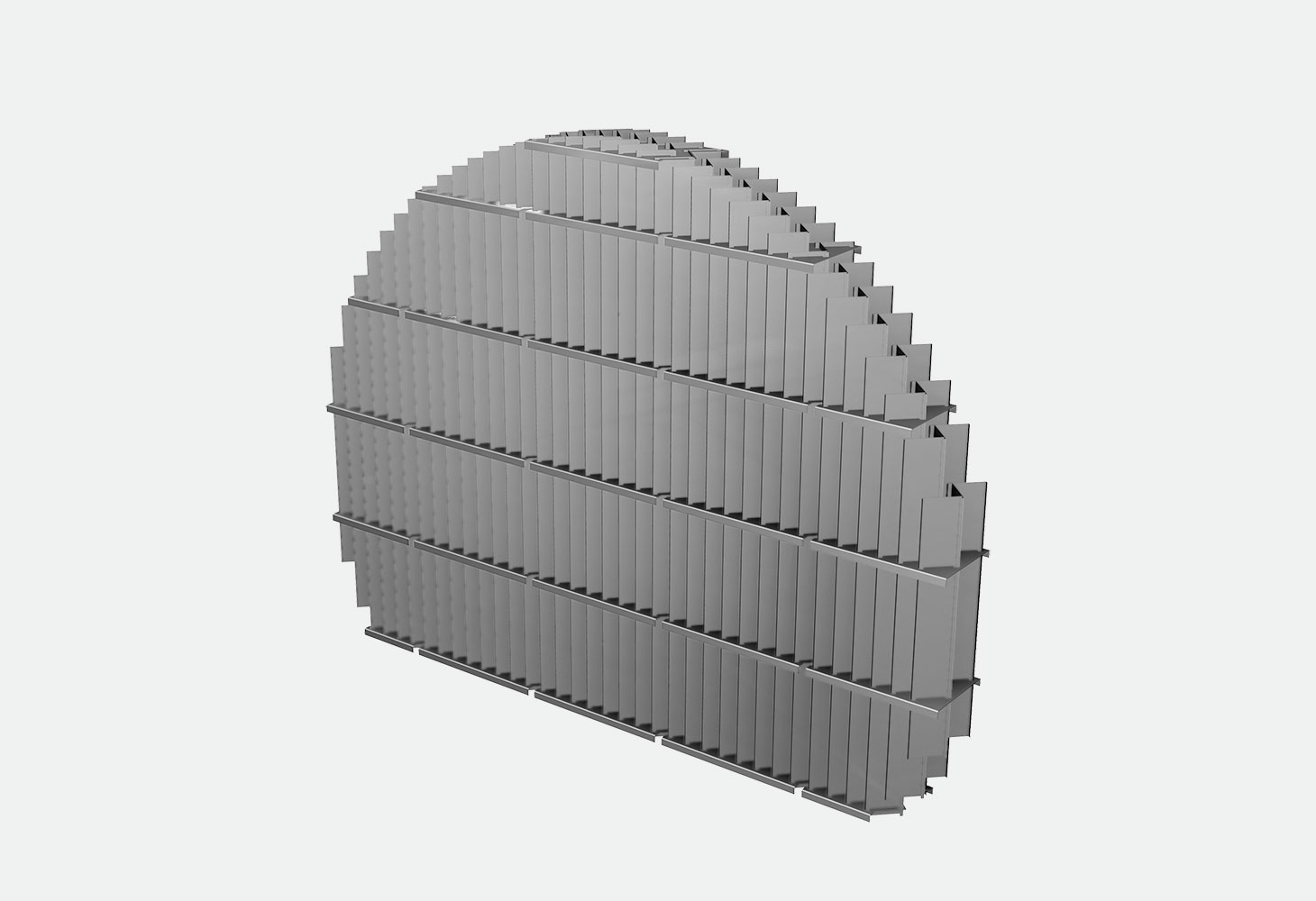

Horizontal liquid-liquid separator

Typical horizontal liquid-liquid separator with perforated pipe inlet distributor, perforated plate calming baffle and VICO-Pack. The presence of a VICO-Pack allows treatment of a slightly foul fluid stream. In the case of clean fluid, a VICO-Tex® Coalescer instead of a VICO-Pack allows higher separation performances to be obtained.

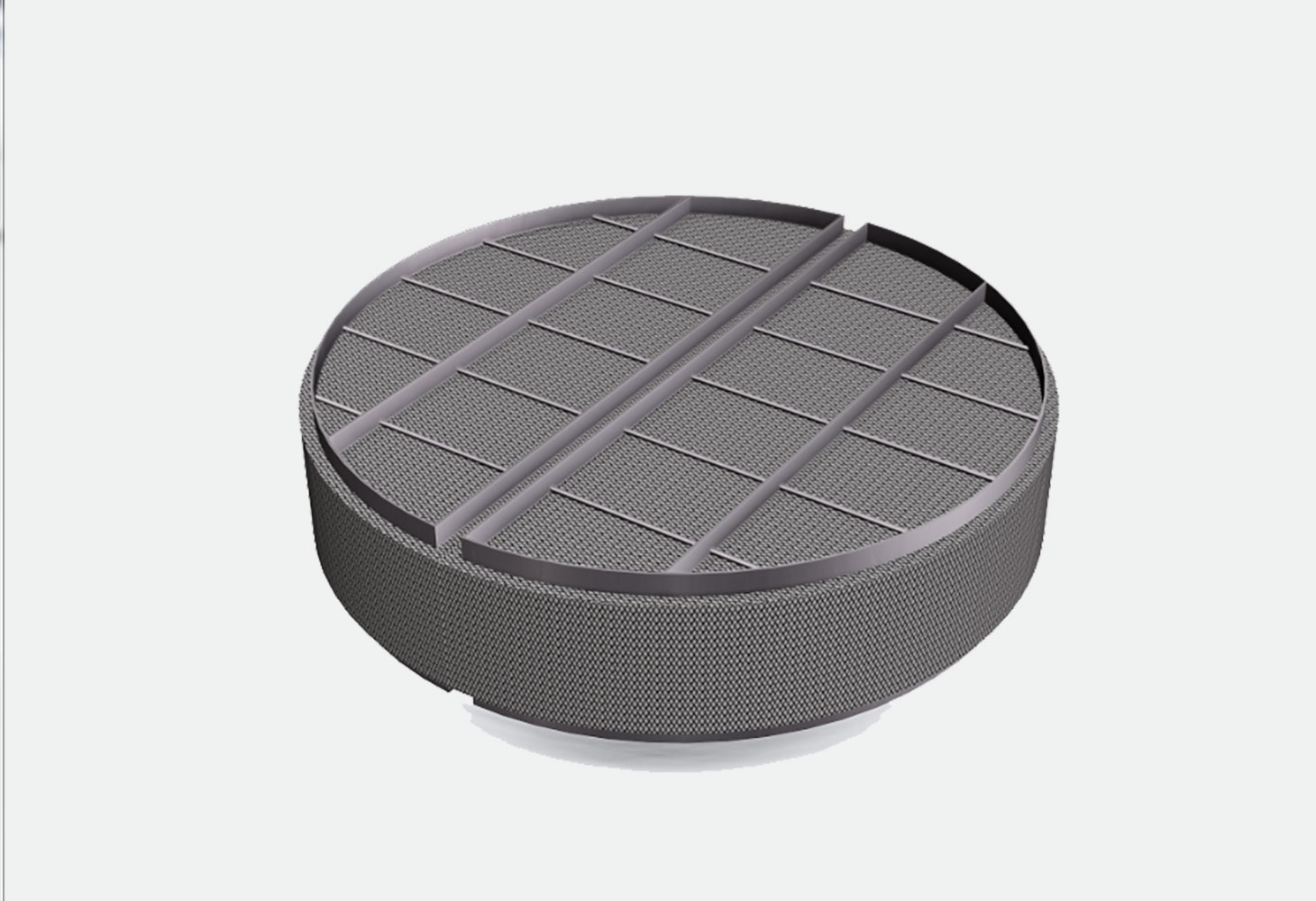

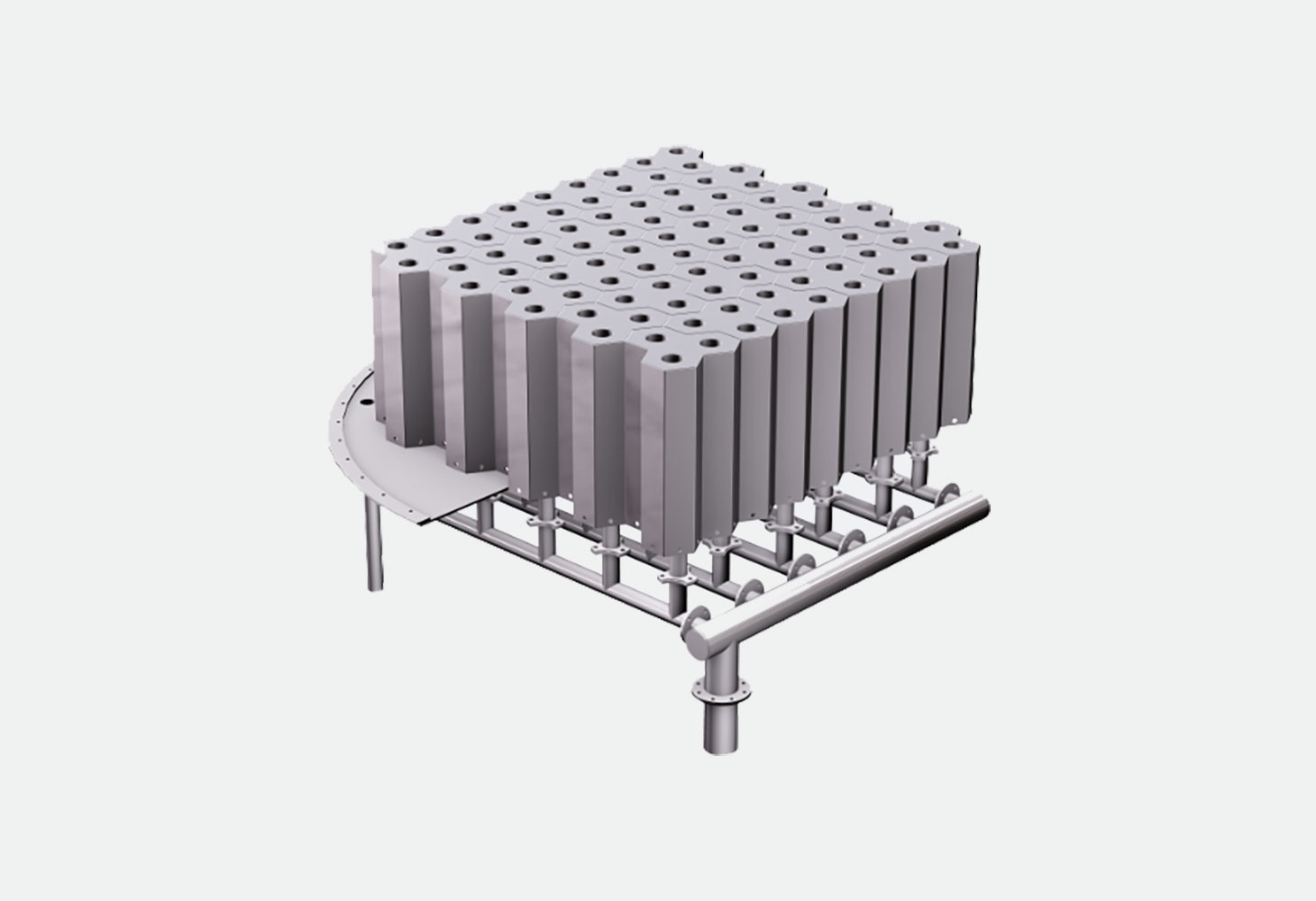

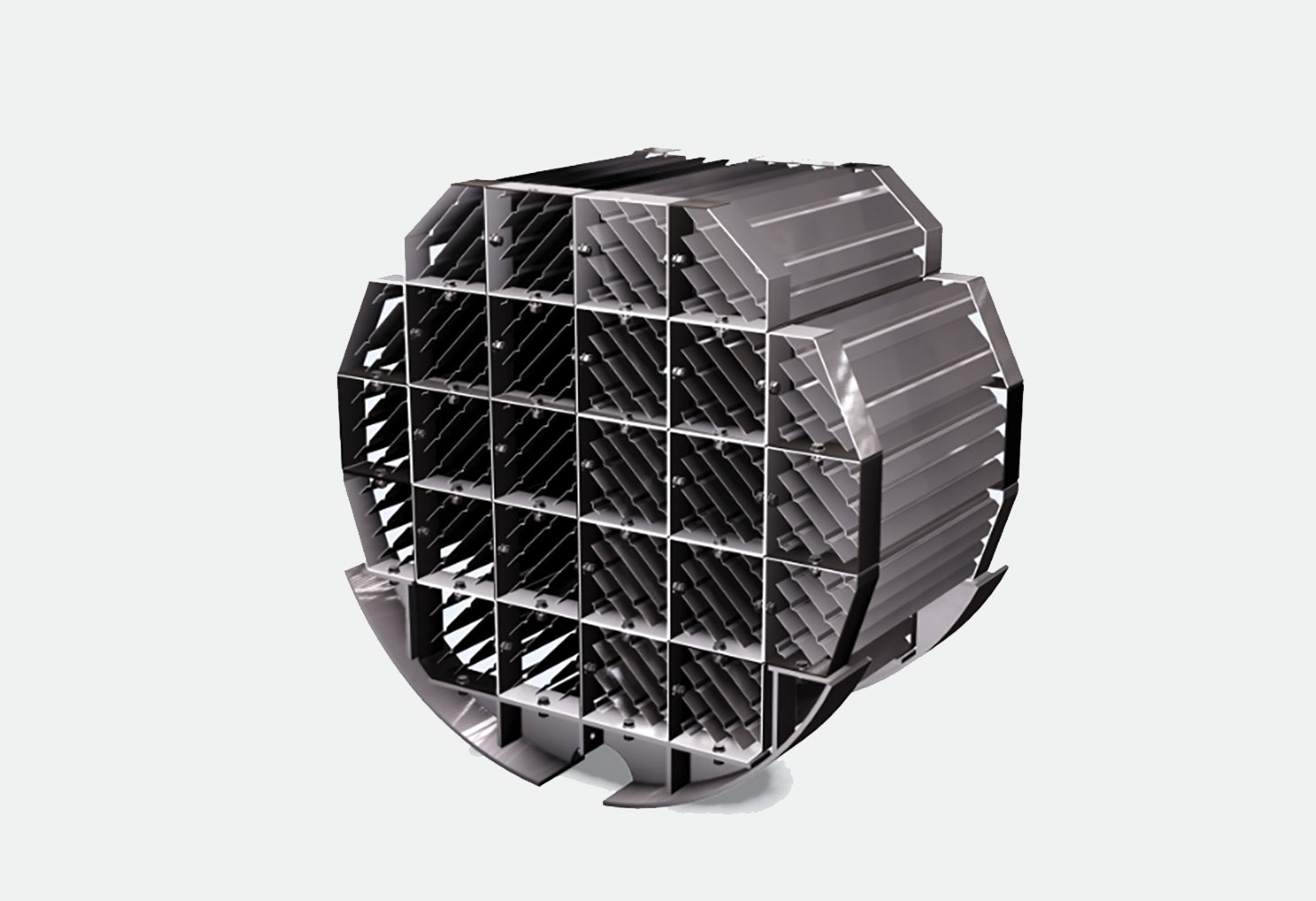

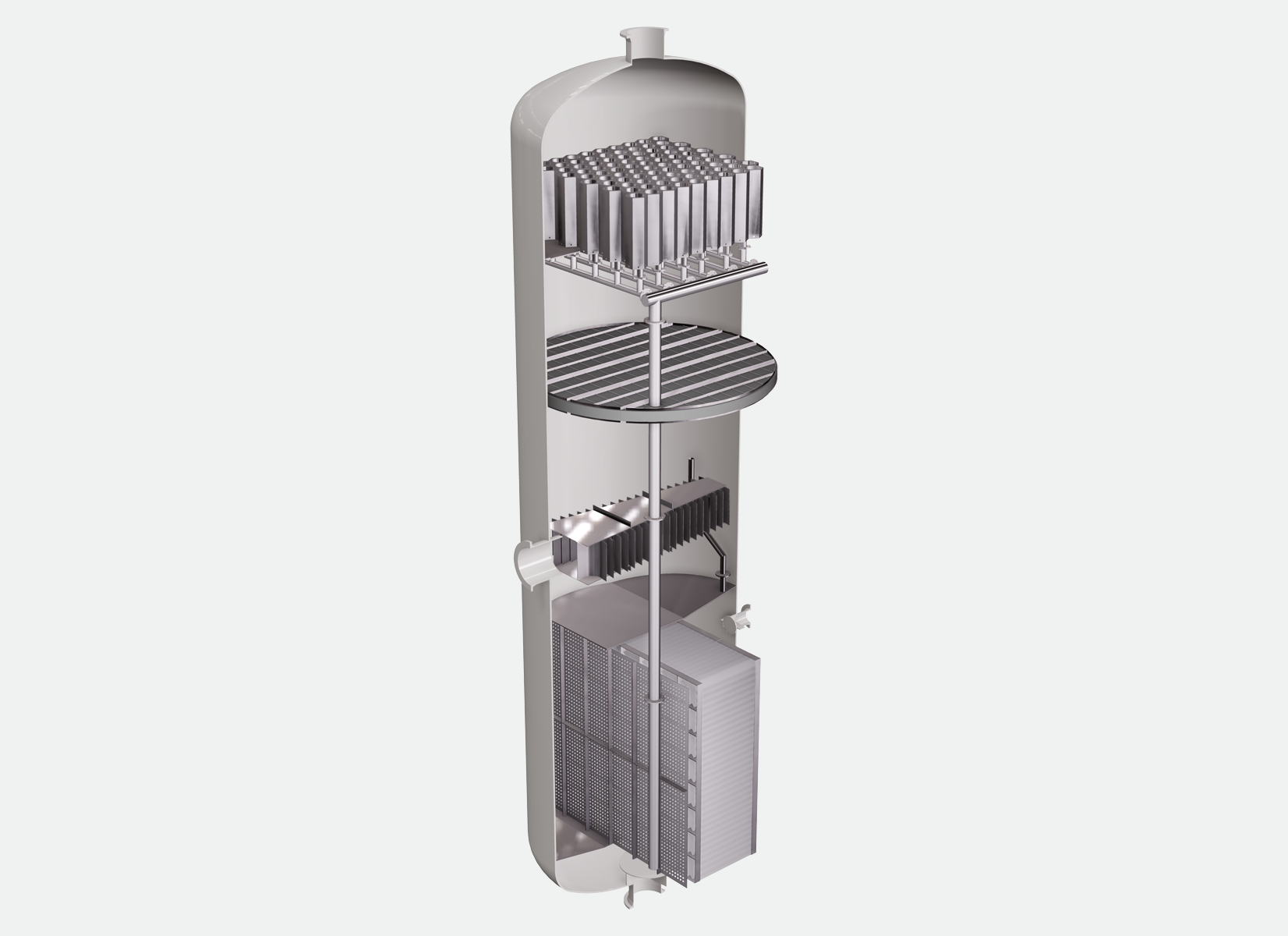

Vertical gas-liquid-liquid separator

Typical vertical gas-liquid-liquid separator equipped with vane feed inlet distributor, perforated plate calming baffle, VICO-Pack, VICO-Tex wire mesh agglomerator and a set of axial VICO-Spin cyclones. This type of separator is recommended when it is necessary to optimise dimensions where the quantity of gas is much greater than that of the two liquid phases.