Costacurta supplies a wide range of products for rock wool production in the thermal and acoustic insulation sectors, such as straight conveyor belts for polymerisation ovens and perforated plates. Perforated plates are used mainly in the production of rock wool fibre

Rock wool is an amorphous silicate obtained from rock and is a very versatile material used above all in construction and widely used for insulation in the nautical sector.

The rock wool production process starts with the crushing of mainly basalt rocks, which are further chopped and mixed with limestone and other elements and, finally, smelted. The smelted rock is transformed into fibres and sprayed with resin and oil.

At the end of the rock wool fibre production stage, the compound is heaped in overlapping layers on conveyor belts that convey it into a polymerization oven: the rock wool layer is reduced in thickness and dried to allow the bond to harden. The rock wool mats that come out of the oven are homogeneous and are then cut and packaged.

Do you have a specific request?

Contact us now

Conveyor belts for polymerisation ovens

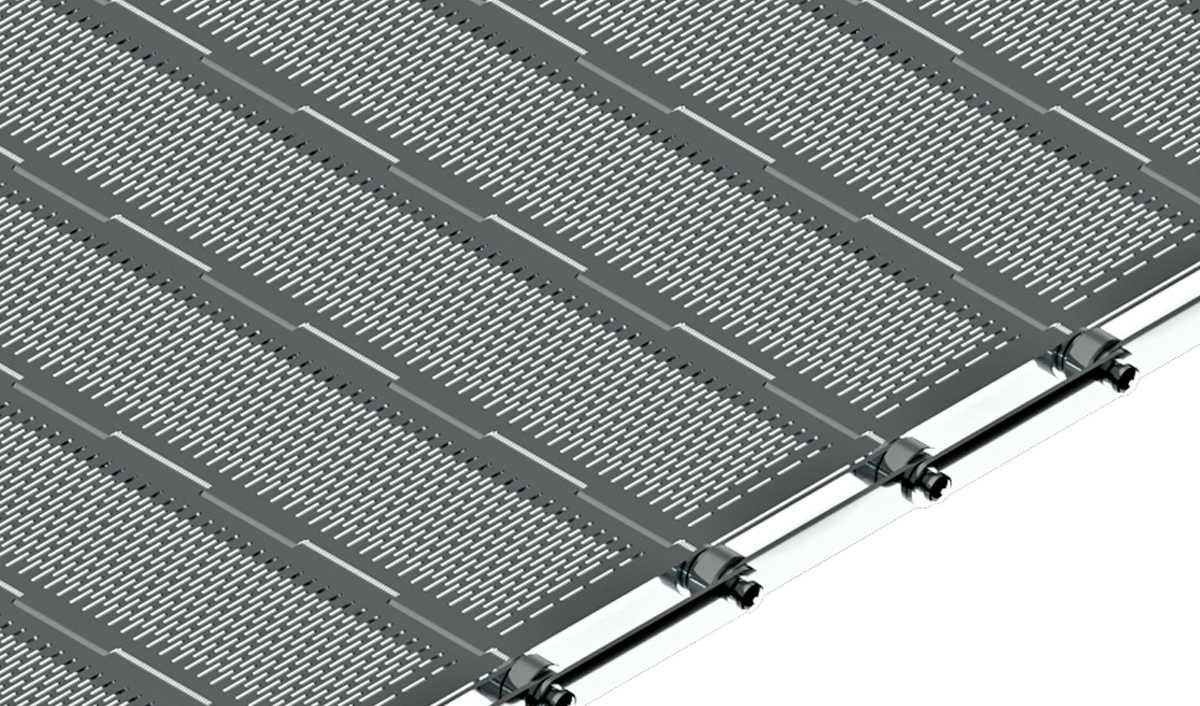

Costacurta conveyor belts are used in polymerization ovens to guarantee a reduction in the thickness of the rock wool mat and its chemical/physical homogeneity when it is taken out of the machine.

Belts for polymerization ovens consist of a set of solid drilled sheets (shutters) hinged to each other in order to guarantee belt continuity. They are assembled on the edges of the chains for transport. The particular design of the holes and linearity of the panel (and belt) surfaces allow efficient heat exchange while at the same time ensuring the uniformity of the insulating mat leaving the oven.

The type of slat conveyor belts used depends on the type of mat to be obtained. Carbon steel slat conveyor belts with a solid structure are preferable for very thick mats (10-15 cm approx.), while stainless steel slat conveyor belts with a less solid structure are preferable for thinner mats (1-2 cm approx.).

Other straight-line conveyor belts made by costacurta are also used in the production of the cupels of rock wool used for the thermal insulation of pipes.

Distinctive characteristics of the costacurta belts for these plants are:

- Precision of the design and the drilling and levelness of the perforated elements

- Precision in the construction of the hinges for joining the perforated elements that form the conveyor belt

- Precision of the mesh geometry and quality of the materials used