Costacurta’s long-standing experience in this sector means it can design, manufacture and supply ideal separation solutions to treat natural gas.

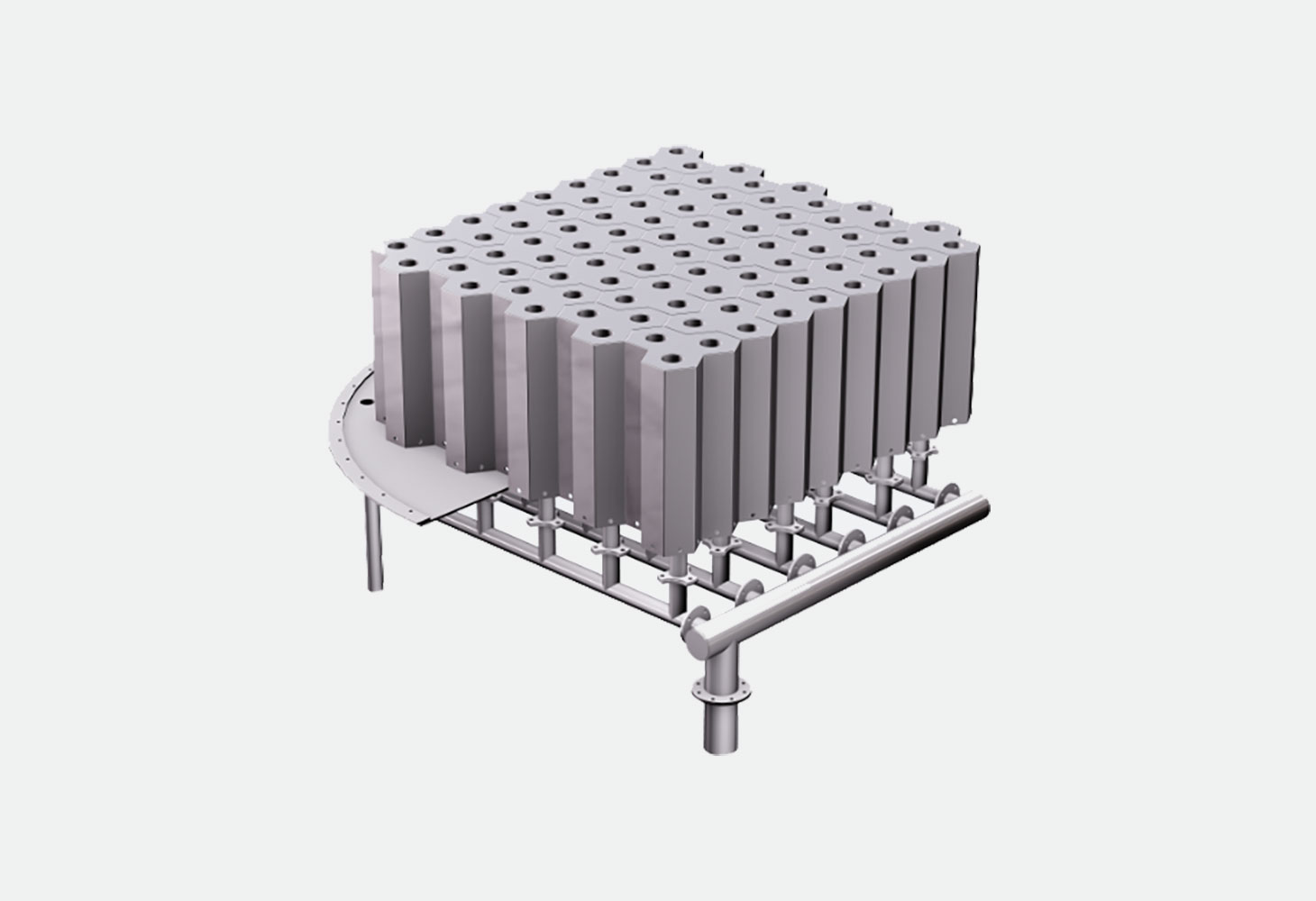

More specifically, the company manufactures vertical and horizontal gas-liquid separator internals.

Natural gas treatment includes all the natural gas treatment and fractionation processes that make its various components available for further industrial operations, such as many petrochemical and chemical processes. This category also includes gas liquefaction to facilitate its transport by ship.

In this case it is necessary to achieve a higher level of purity of the gas upstream of the lng plants. The production plants are normally located in strategic locations onshore and receive gaseous hydrocarbons obtained in the oil & gas production plants.

This application includes:

- Compression of gaseous hydrocarbons, in which there can be several vertical gas-liquid separators such as ‘suction ko drums’, ‘interstage ko drums’ and ‘discharge ko drums’

- Dehydration, where there can be several gas-liquid and liquid-liquid separators such as ‘glycol contactors’, ‘inlet separators’, ‘flash separators’, ‘low temperature separators’ and ‘miscellaneous ko drums’

- Liquefaction, in which there can be several vertical gas-liquid separators such as ‘inlet separators’, ‘overhead reflux drums’, ‘suction ko drums’, ‘interstage ko drums’, ‘discharge ko drums’, ‘demisters at the top of absorption columns’

Costacurta’s team of process engineers choose and design the correct set of internals based on the operating conditions (temperature and pressure), and the process fluids’ properties (flow rate, density, viscosity and surface tension). They guarantee separation efficiency and minimise pressure drops, weights, dimensions and costs of the internals and separators in which they are installed.

Do you have a specific request?

Contact us now

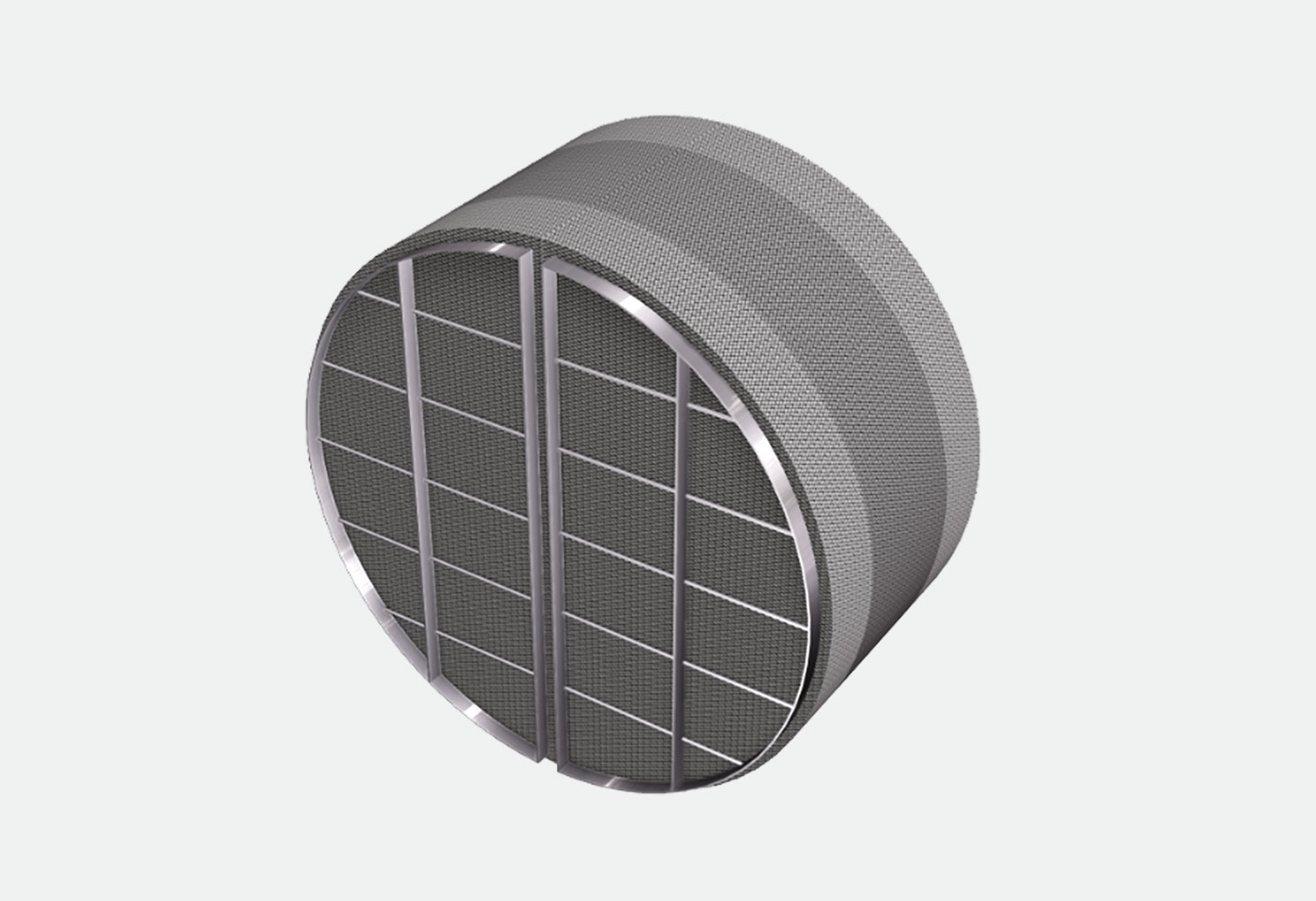

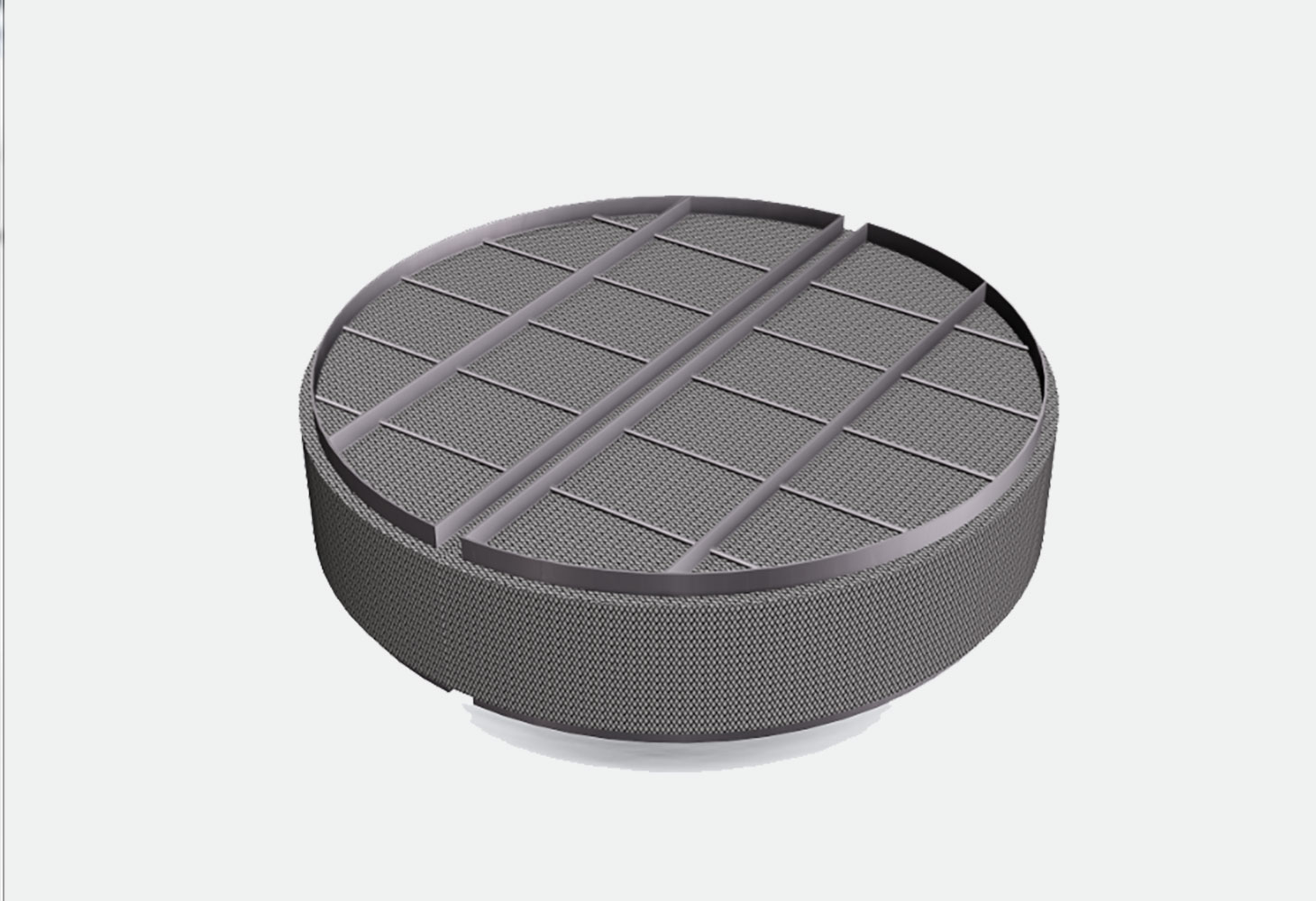

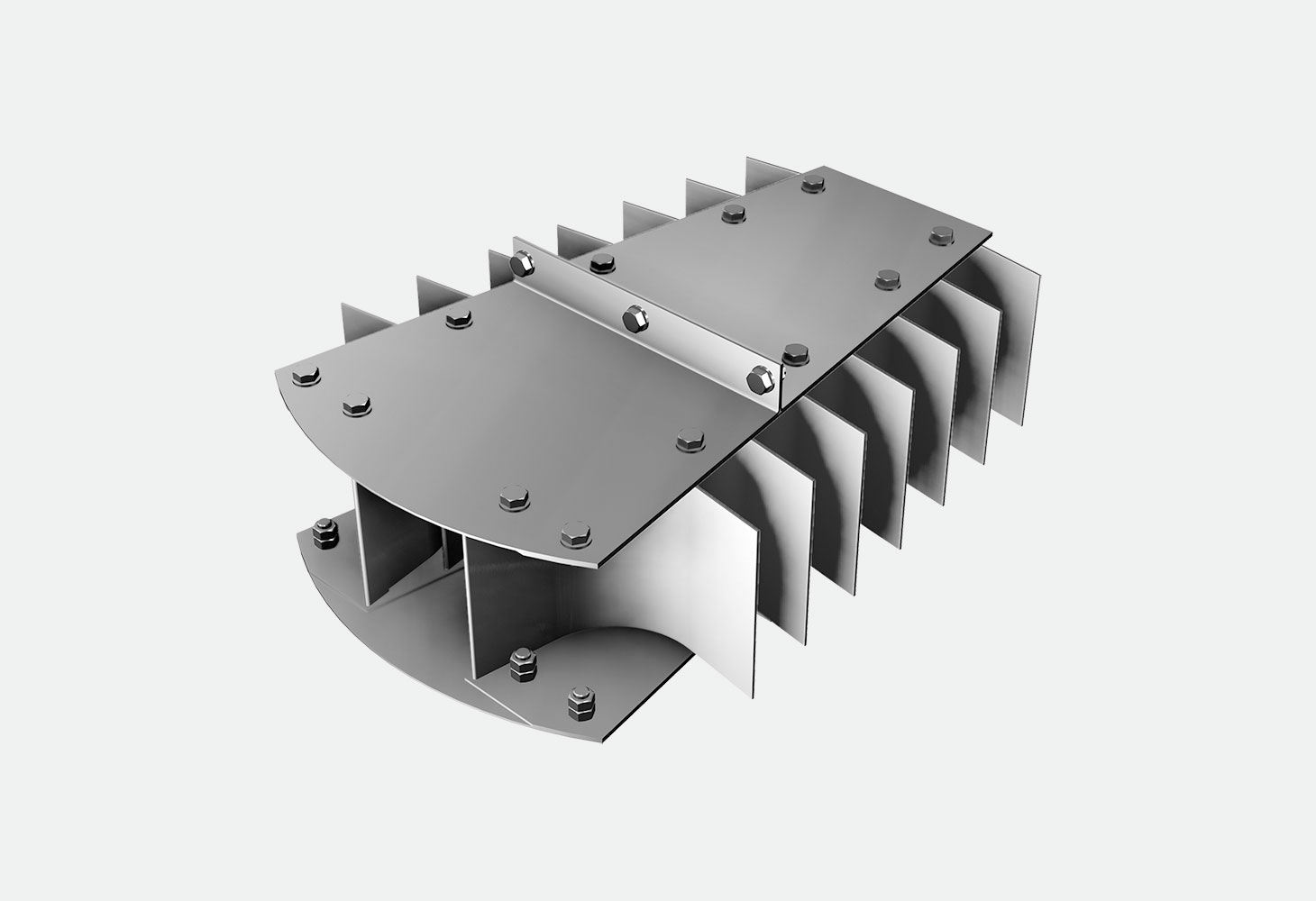

Vertical gas-liquid separator

Typical vertical gas-liquid separator fitted with a vane feed inlet distributor, a VICO-Tex agglomerator and a VICO-Spin. The combination of a VICO-Tex agglomerator and a VICO-Spin has two main advantages:

- High separation performances at high velocity, thanks to the coalescence effect provided by the agglomerator.

- High turndown: the VICO-Tex acts as main separator at low gas velocity, maintaining a high efficiency level.

This combination of internals is widely used in gas compression trains or for the retrofitting of existing equipment.

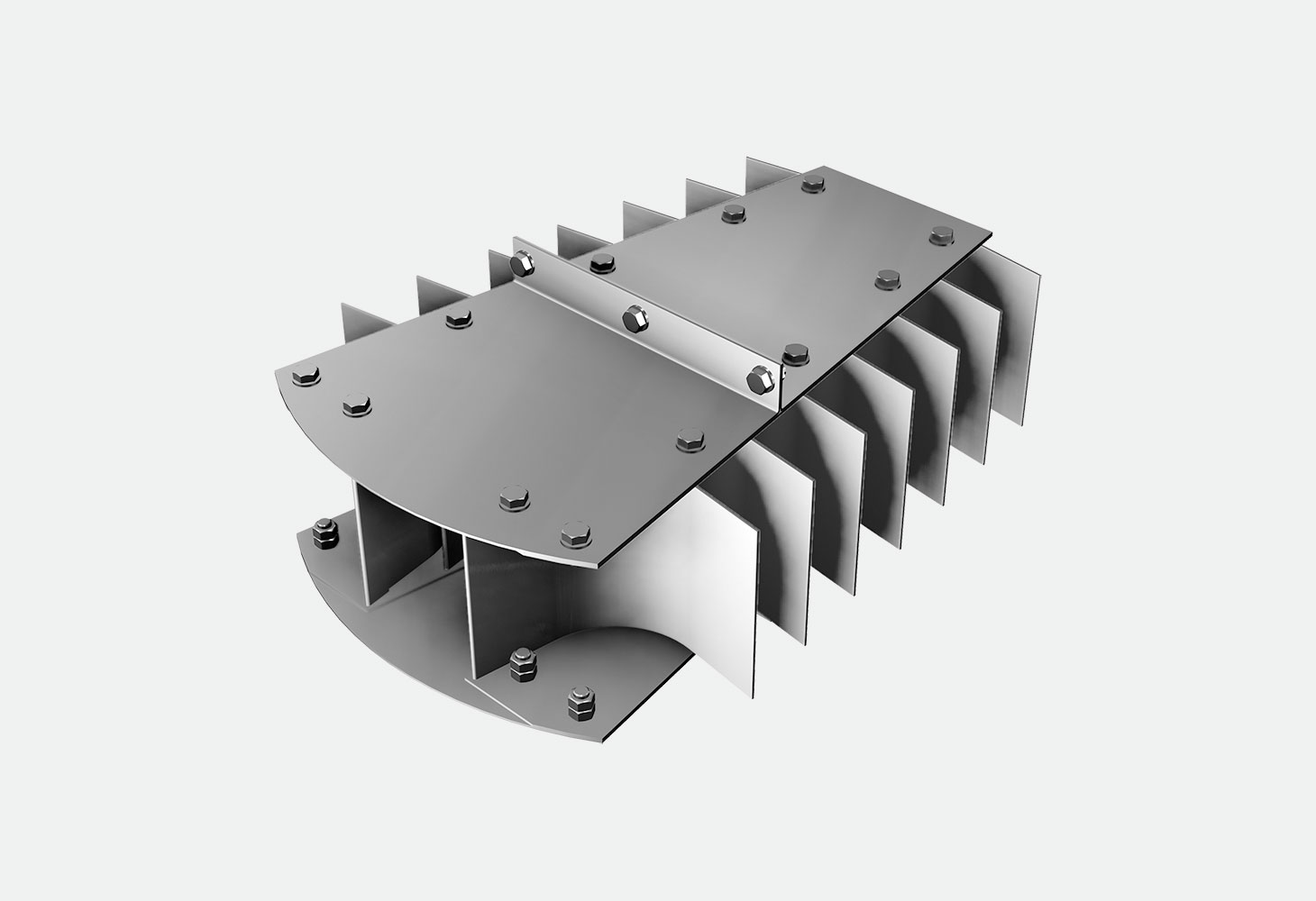

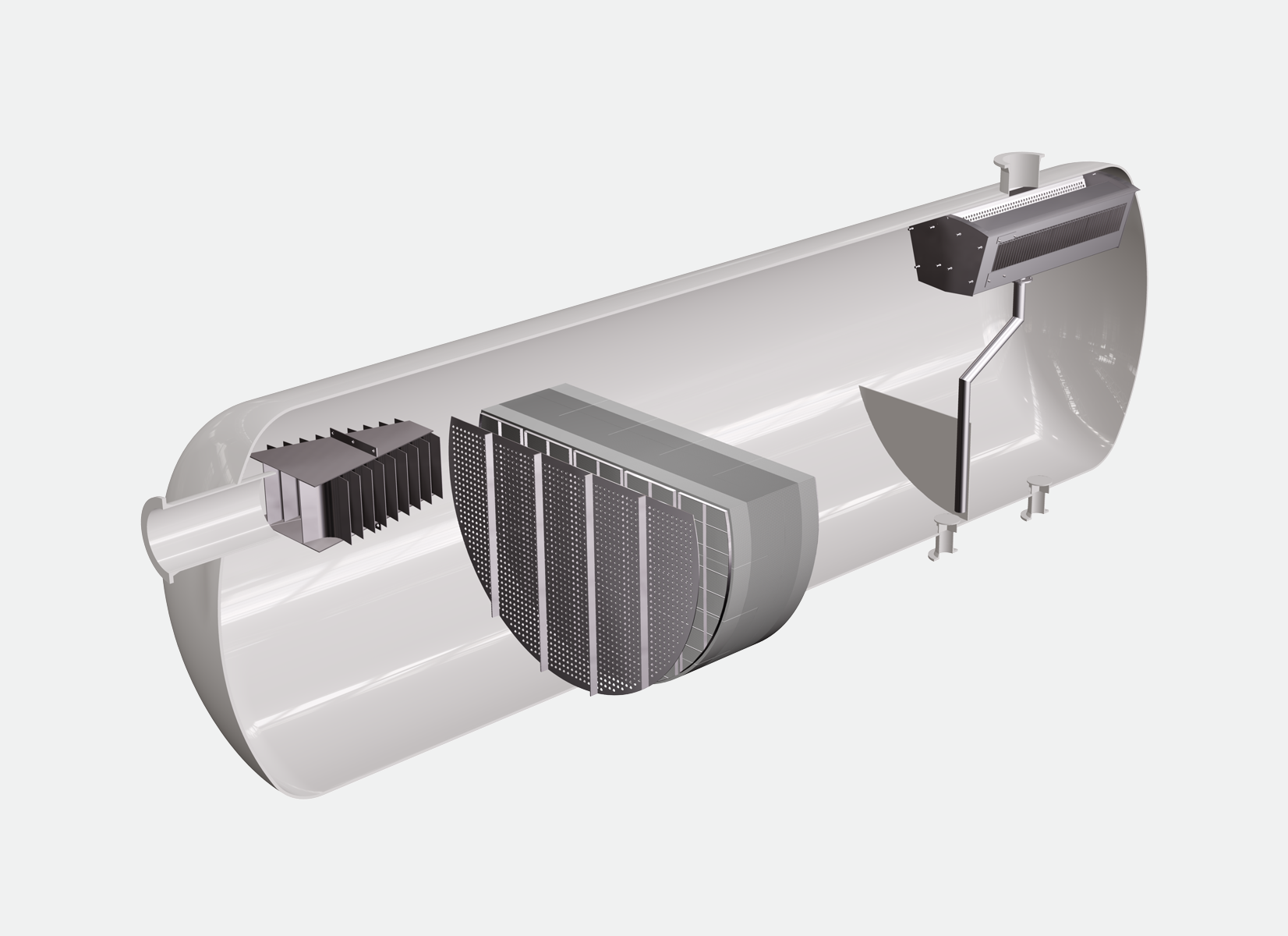

Horizontal gas-liquid-liquid separator

Typical horizontal gas-liquid-liquid separator equipped with a vane feed inlet distributor, perforated plate calming baffle, VICO-Tex coalescer and VICO-Vane at the gas outlet.

This type of separator is widely used when the separation of liquid-liquid secondary dispersion is required and the fluids have no propensity to cause fouling.