Costacurta is specialised in the mechanical engineering and manufacture of downflow reactor internals for hydrotreating used in the refinery sector.

The hydrotreating process aims to remove contaminants (sulphur, nitrogen, metals) and saturate the olefins and aromatics to obtain a clean product ready for sale or further processing.

The hydrotreating unit removes sulphur from naphtha for use in downstream processes such as isomerization and catalytic cracking, removes sulphur from petrol and diesel to meet recent clean fuel specifications, removes sulphur from kerosene for home heating. Finally, it converts kerosene into jet fuels through a mild aromatic saturation process.

Do you have a specific request?

Contact us now

Hydrogenation reactor

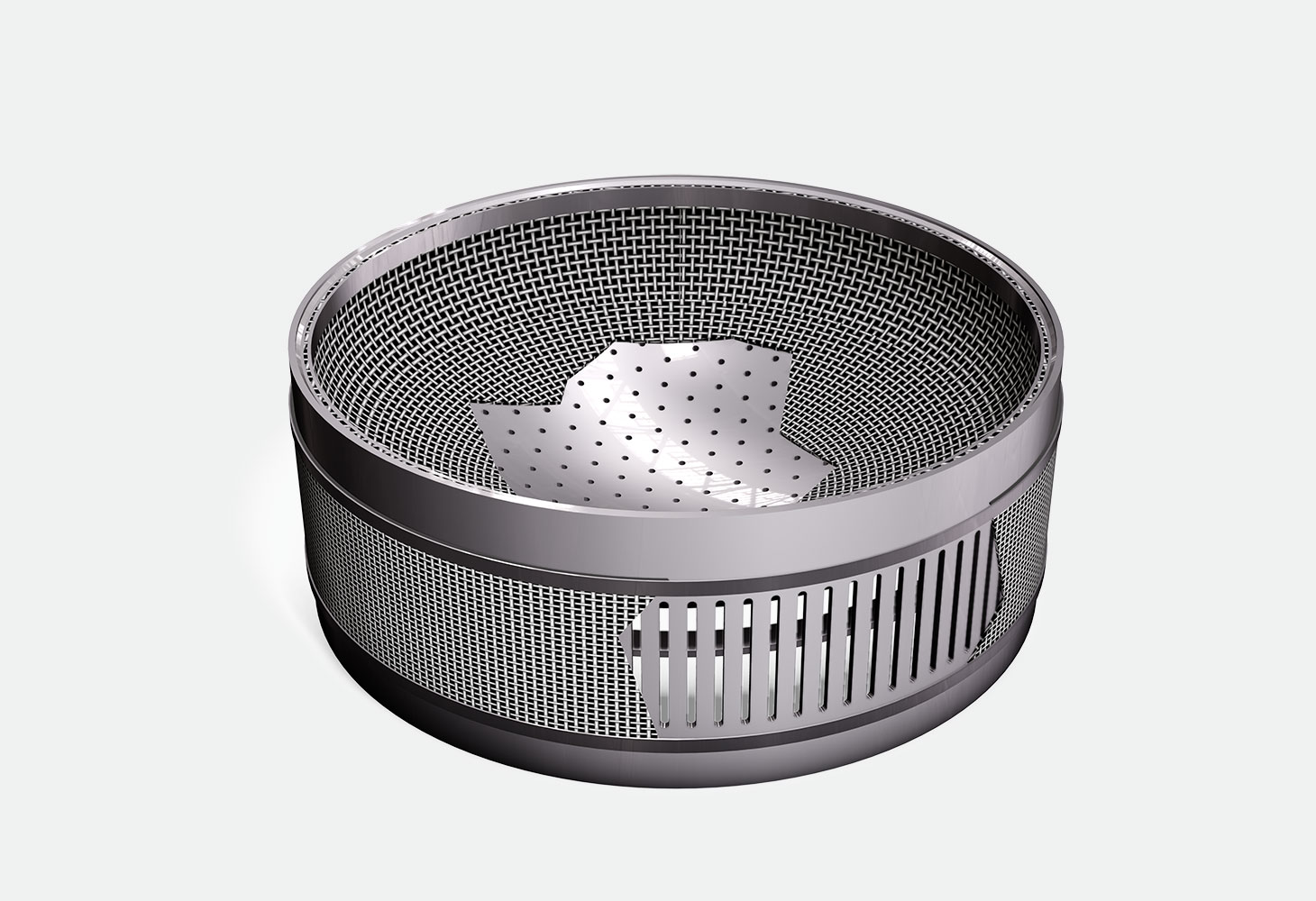

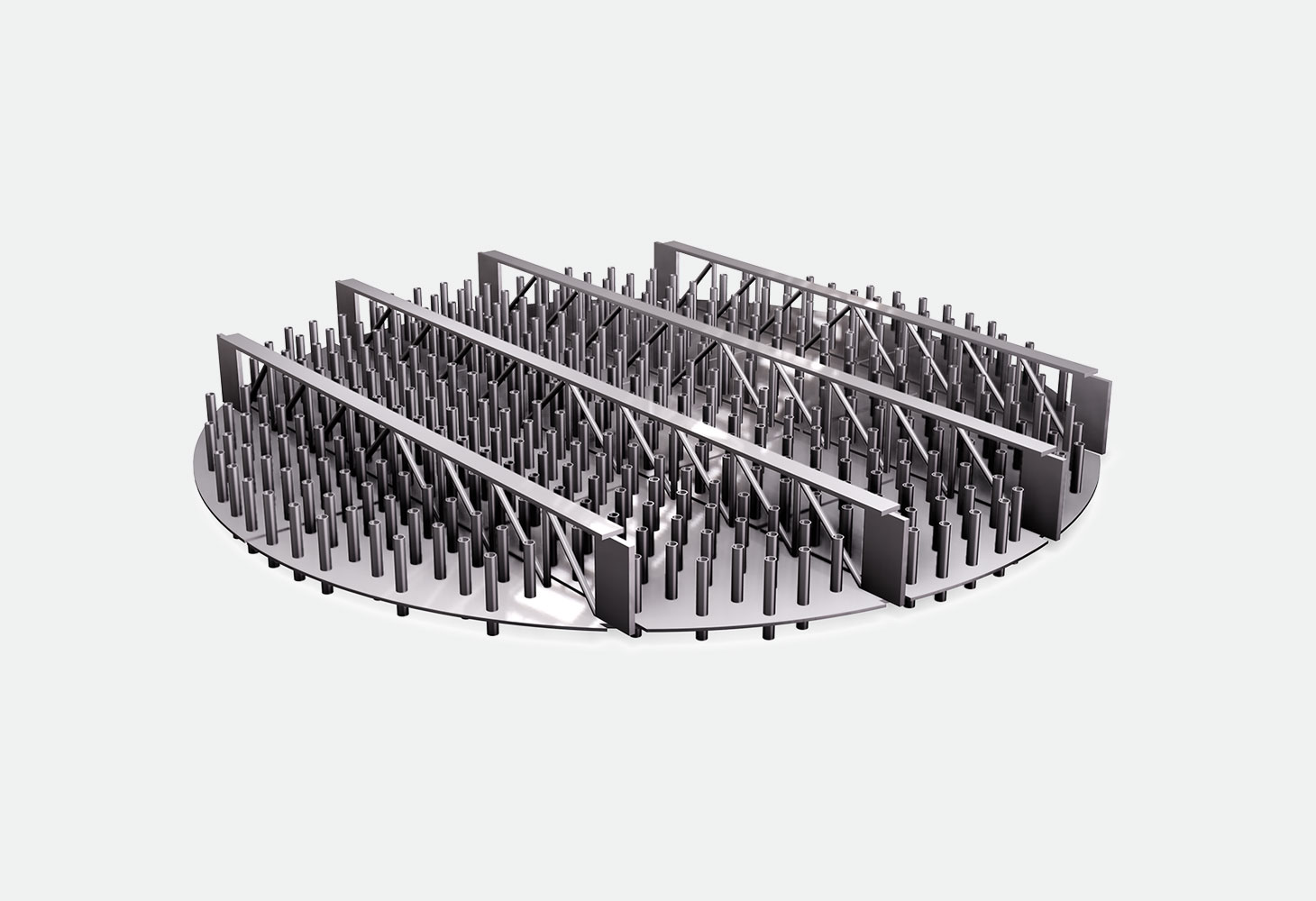

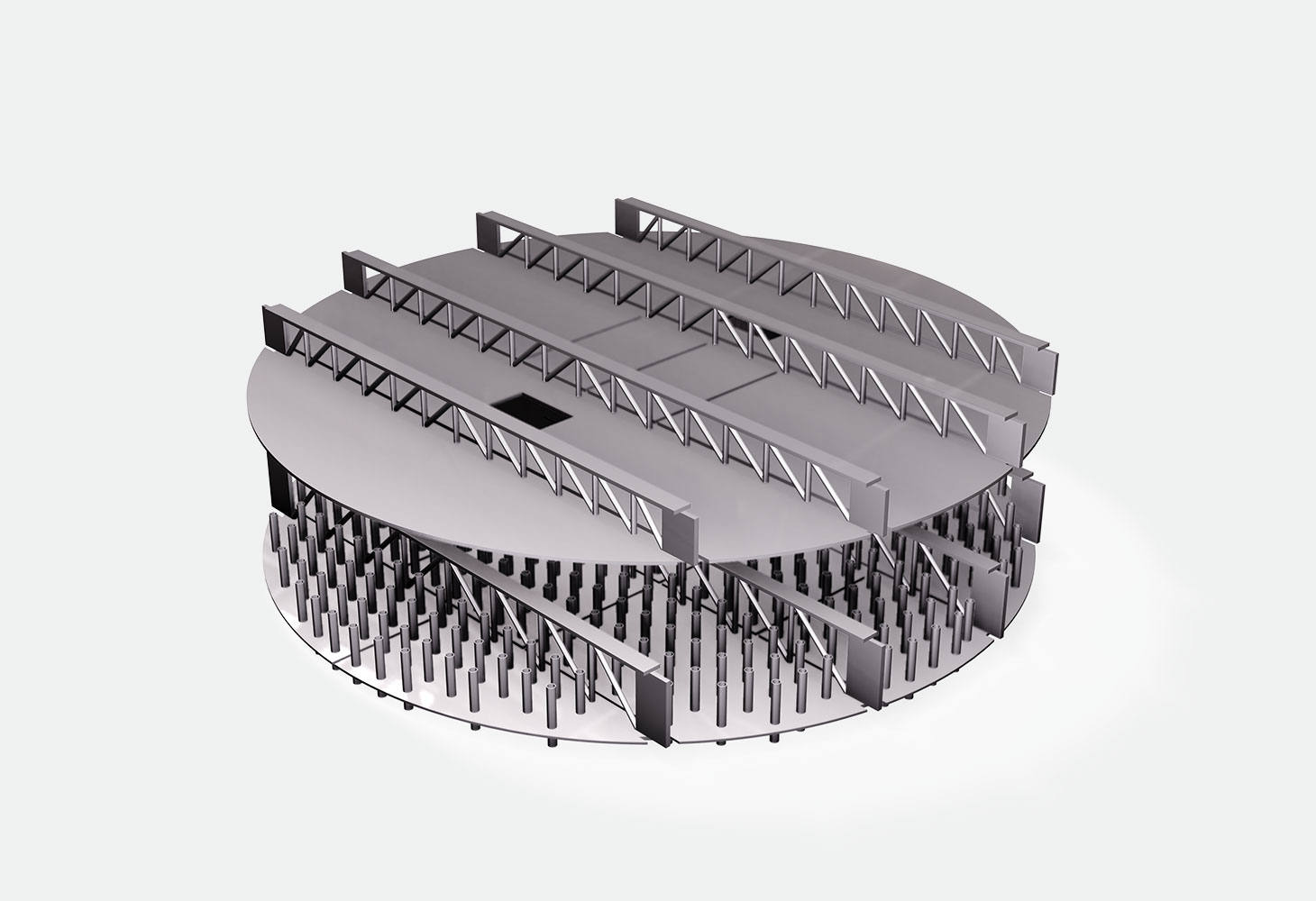

The hydrotreating unit consists of a hydrogenation reactor (down flow type) where the feedstock, with added hydrogen, flows from top to bottom through different types of catalysts depending on the desired reactions, thanks to the presence of internals (‘distributor and redistributor trays’, ‘mixing trays’, ‘catalyst support grids’ and ‘outlet collectors’). The hydrotreating unit removes all contaminants and saturates the aromatics as a pre-treatment for the Fluid Catalytic Cracking loads.

Distinctive characteristics of the Costacurta down flow reactor internals for the hydrotreating process are:

- Internal production of all the filtering elements used in making the internals (wire cloth weaving, punching and production of wedge wire screens)

- Internal production of all the internals, from the ‘inlet’ to the ‘outlet collector’.

- Over 60 years of experience in mechanical design and construction of internals

- Availability of dedicated teams highly experienced in project management