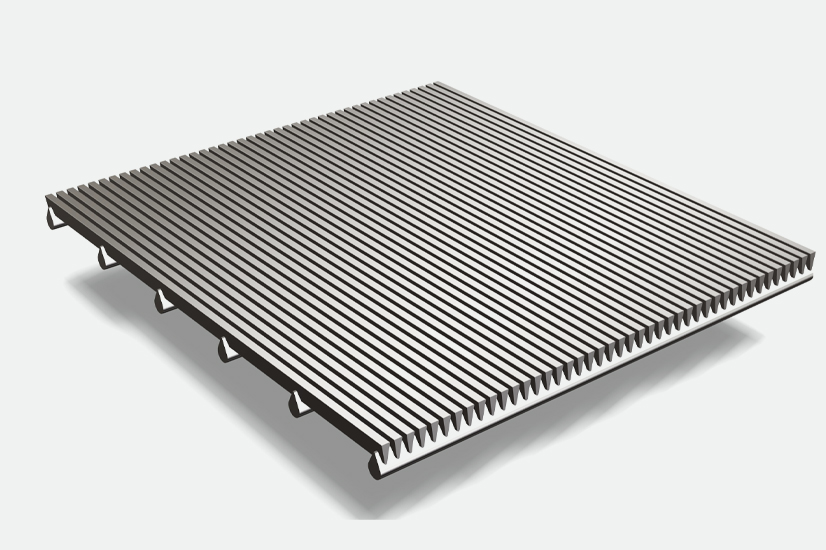

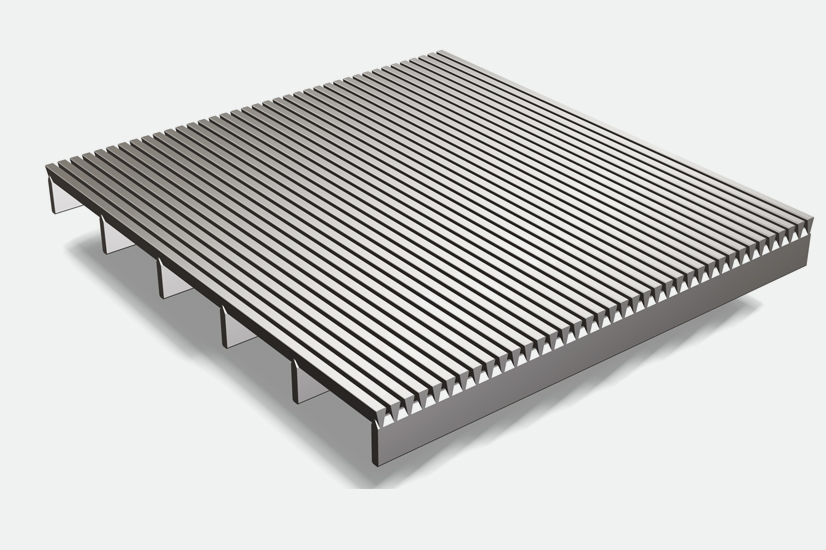

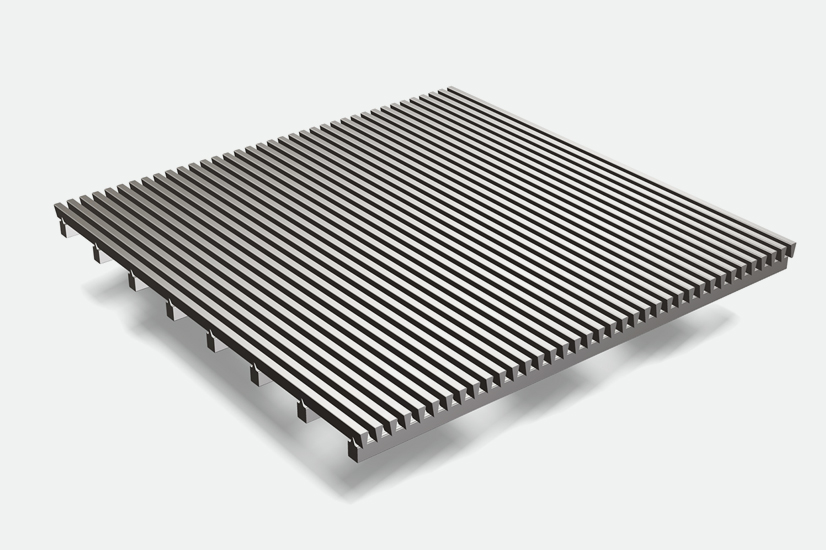

Flat and curved panels are obtained by flattening the machine-manufactured cylinders and, in the case of the curved panels, subsequent rolling.

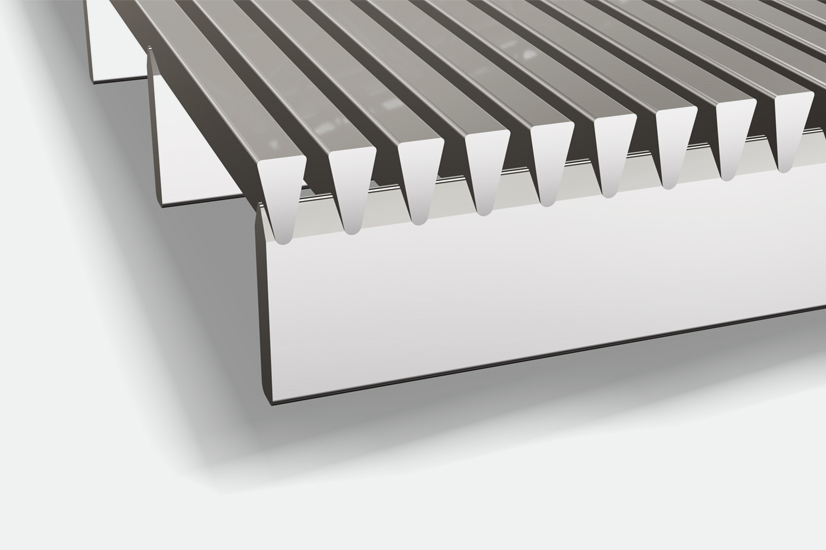

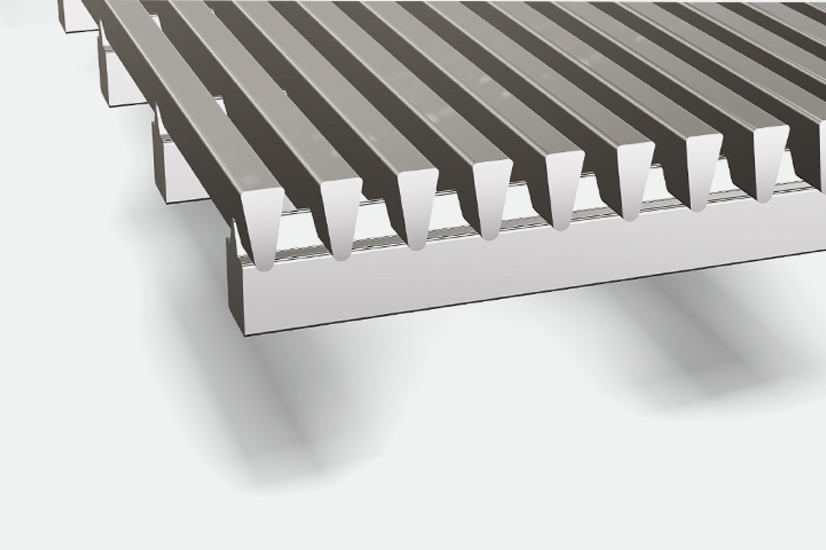

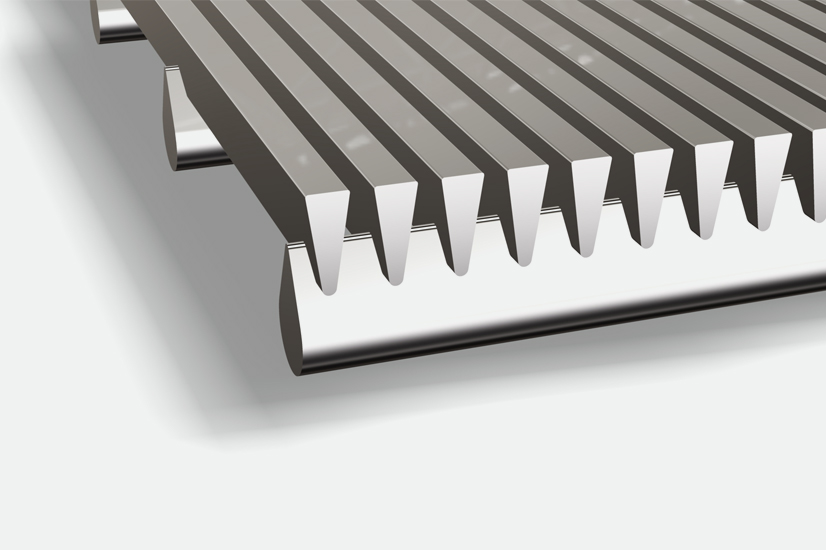

Flat panels are used in a range of different filtering processes. One of the main advantages of the VICO-Screen panels is their capacity to prevent clogging thanks to the special wire with “V” section that ensures uniform flow of liquids and to the inclination of the wire.

In accordance with the client’s needs, it is possible to make these flat panels with very small slots, using a wide range of wires and guaranteeing the correct filtering value.

The advantages of this product compared to filtering elements in wire cloth include: high tensile strength, and therefore ideal for use in operating conditions that entail high loads, larger open area with the same slot dimension, smooth filtering surface and an open area section with anti-clogging shape.

Do you have a specific request?

Contact us now

Materials

Carbon steel, AISI 304, AISI 316L, AISI 321, AISI 321H, AISI 347, duplex, super duplex, Nickel-Chromium alloys

Supply

On request, the VICO-Screen panels can be supplied complete with edging or reinforcement elements in accordance with the client’s specifications and drawings.

On request, surface finishes can be applied such as degreasing, pickling and electropolishing.

Use

The shape of these panels makes them ideal for small and large rate filtering and sieving systems such as lauter tuns, sieve bends, vibrating screens and static screens. The panels are often used in the food (beer fermentation), mining (in vibrating screens and sieves), pharmaceutical (fluid beds), energy (water treatment for plants) sectors and many others.

DISCOVER THE OTHER WEDGE WIRE SCREEN