The Costacurta VICO-Flex Drum Driven system is a simple and efficient system for the conveying of food products in particular operating conditions. The system comprises special plastic bars, designed on the basis of the operating conditions of each application, and a VICO-Flex belt that is highly similar to the belts installed on low-tension towers. The VICO-Flex Drum Driven system keeps the conveyed products stable and, in the operating conditions for which it is recommended, has a lower tension than a low-tension system. The system also has the advantage of being highly similar in its design criteria to a low-tension system, making the design of a new tower easy and, where necessary, allowing a rapid, simple and efficient conversion of the system from low-tension to positive drive.

Do you have a specific request?

Contact us for adviceWHEN AND WHY THE VICO-FLEX DRUM DRIVEN POSITIVE DRIVE SYSTEM SHOULD BE USED

There are two main advantages to choosing a VICO-Flex Drum Driven system:

- product stability

- lower tensions on the belt in certain operating conditions resulting from the combination of two elements: the product and the process.

Choosing a VICO Flex-Drum Driven system is therefore recommended when:

- it is necessary to convey products that could be damaged by the typical continuous small movements of the connecting rods of low-tension systems, such as soft dairy products or crumbly pastry products, but also when the products must remain in the same position while being conveyed, so that they can by channelled and aligned within the lanes on exiting the tower

- the combination of product and process leads to a significant reduction in the friction coefficient between the belt and the bars, due to the presence of grease/fat or ice.

In a low-tension system, this latter condition causes a substantial increase in tension on the belt, which, in certain circumstances, can reach the point of damaging it. In contrast, on a drum driven system, these operating conditions not only do not cause an increase in tension, but can actually reduce it.

However, in conditions where dry residues form or in processes that require warm and/or dry air, the use of a VICO-Flex Drum Driven system is not advisable. Instead, a traditional low-tension system is the preferable solution.

Our engineers can provide a free consultancy on choice of the belt and the system (low-tension or Drum Driven) that is best suited to the specific operating conditions.

CASE STUDY – FREEZING OF VEGETABLES - CONVERSION OF A LOW-TENSION SPIRAL TOWER INTO A VICO-FLEX DRUM DRIVEN SYSTEM

Introduction

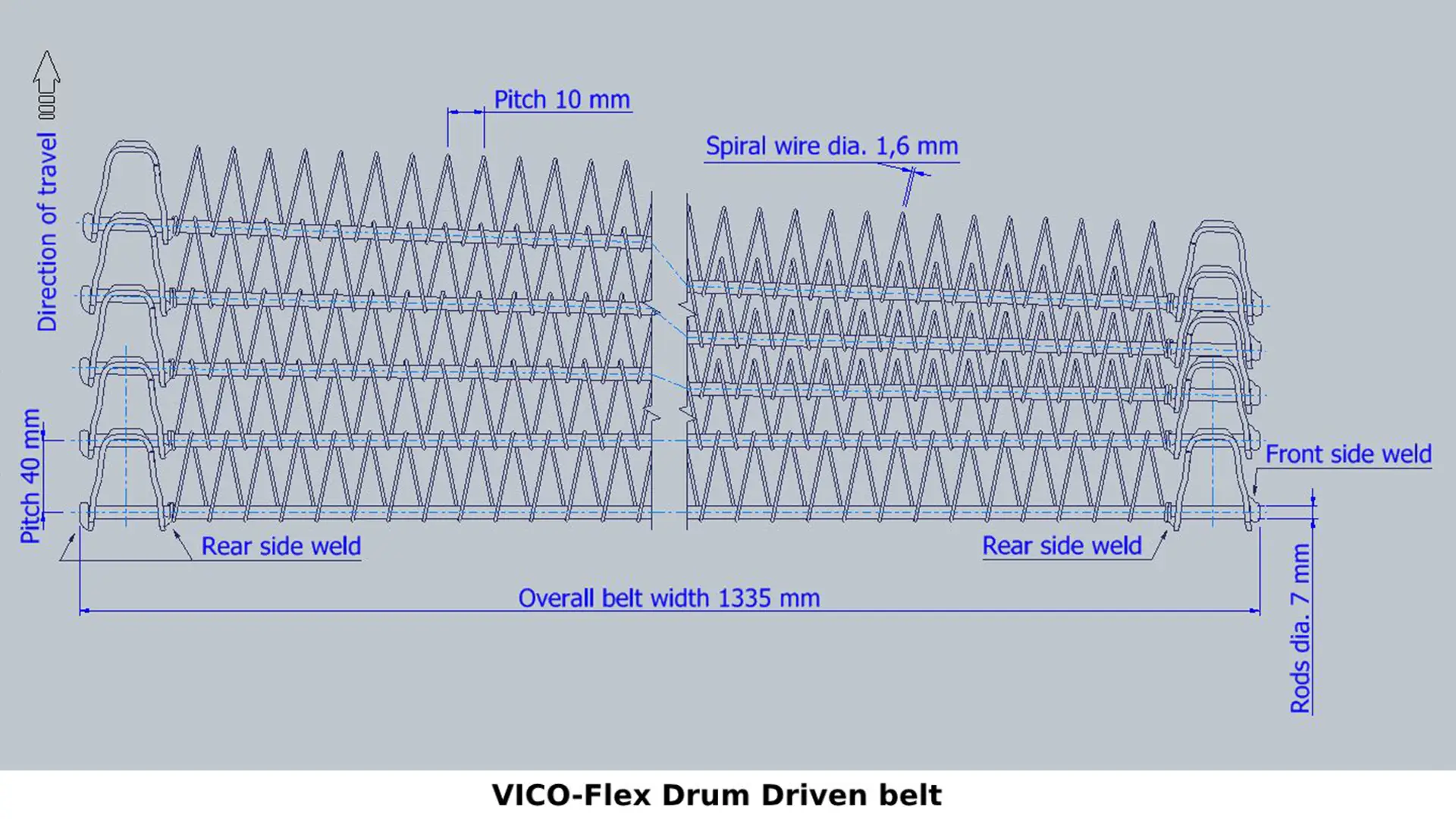

An important producer of frozen vegetables had a problem of excessive tension on the conveyor belt of its freezing system, which had a drum of 4300 mm in diameter and a VICO-Flex EHD3 belt of 1335 mm in width, and was designed to process large quantities of vegetables. The high tension, which led to frequent breakages of the belt, was caused by the formation of ice, which reduced the friction coefficient between the belt and the bars.

Costacurta suggested to the customer the adoption of the VICO-Flex Drum Driven positive drive system, with the aim of reducing the tension on the belt, and thus the risk of breakages, with positive effects on the continuity of operation of the system and on the useful lifetime of both the belt and the system as a whole.

Low-tension mode

The freezing system has been designed to process around 10kg/m of vegetables. This figure means that the overall quantity of product moved inside the tower, plus the weight of the conveyor belt itself, forms a total mass to be moved of around 20 tons. In order to move this mass, the low-tension system was provided with a high number of bars and a counterweight of around 200 kg.

In the low-tension configuration of the tower, the tension on the belt, at working temperature, with a clean system and no load, reached extremely high values close to the maximum allowable tension of the belt. This was also due to the 200 kg counterweight, which increased the incoming tension at the tower.

The system was also monitored during operation, using a specific tension measuring instrument. At the operating temperatures (-30°C/-40°C) and with a load of spinach of 10.5 kg/m, the tension on the belt reached values as high as 4500 N, and therefore over twice the maximum allowable tension of the belt, which was 2002 N.

Condensation of the water vapour present in the environment, produced by the vegetables, caused the formation of ice on the system components. Although the ice on the support guides improved friction and sliding of the belt, the ice on the drum bars greatly reduced the friction coefficient between the belt and the bars, causing a considerable increase in tension on the belt.

Drum Driven mode

After a discussion with the Costacurta technicians, the customer decided to try the Drum Driven (positive drive) solution, replacing the conveyor belt previously installed with an equivalent VICO-Flex Drum Driven belt.

Some of the bars were altered to guarantee engagement between the belt and the drum and therefore correct driving of the belt.

An auxiliary input motor was also added to allow a significant reduction in the tension on the belt at the entry to the tower. The tension also remains limited even after insertion of the belt into the tower, thanks to the specific shape of the bars. The special drum bars guarantee efficient transmission of the drive force also when ice is present. In Drum Driven systems, reduction of the friction coefficient between the belt and the bars has even a positive effect, because it facilitates vertical sliding of the belt.

The tension was further adjusted at the exit from the tower by installing a recovery motor at the outfeed.

Conclusions

In this specific case, where there is a heavy load and ice is present, the Drum Driven system proved to be an efficient solution in mitigating the problems of breakage of the belt caused by excessive tension. In the case study described, minimal alterations were made to the initial system:

- Replacement of the belt

- Modification of some of the drum bars

- Installation of an input motor and a motor at the outfeed to adjust the tension.

The maximum tension found with the same operating conditions, i.e. -40° with a load of 10.5 kg/m, was 1200 N in the Drum Driven System, compared with 4500 N in the low-tension system.

Do you need support in solving a problem or designing a new system with similar operating conditions?