Costacurta designs and produces straight and curved conveyor belts for use in straight tunnels and spiral towers. The conveyor belt is designed to facilitate the transport and pasteurization of foods based on the plant layout, operating conditions and characteristics of the product.

Moreover, the conveyor belts are easy to clean and made of high-quality materials to guarantee utmost hygiene.

As well as guaranteeing a high-quality product, costacurta provides technicians and engineers to assist clients in the selection of the belts and their installation.

Pasteurisation is a thermal reconditioning process in which all the pathogenic microorganisms present in liquid or semi-liquid foods are destroyed. It typically occurs at temperatures ranging approximately between 60°c and 85°c; this process increases the food’s shelf life and reduces the risk of bacterial contamination, keeping the quality of the product almost unaltered.

Some products normally subject to pasteurisation are fruit juices, sauces, preserves, beer and wine.

Do you have a specific request?

Contact us now

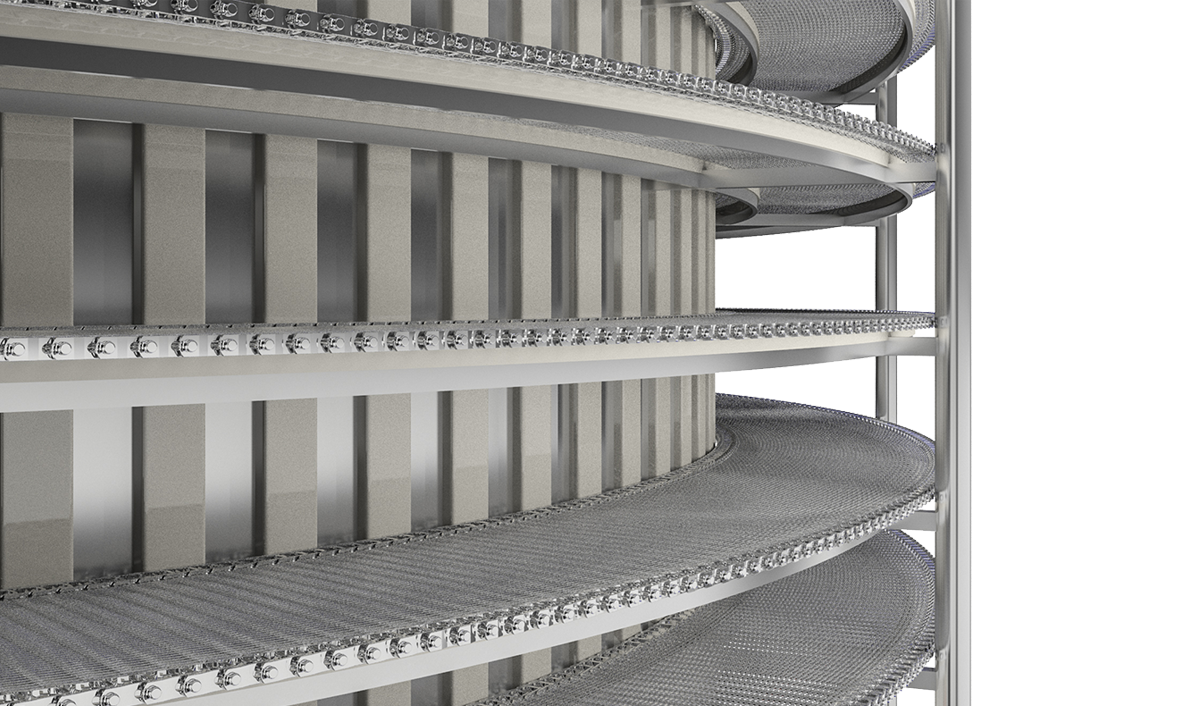

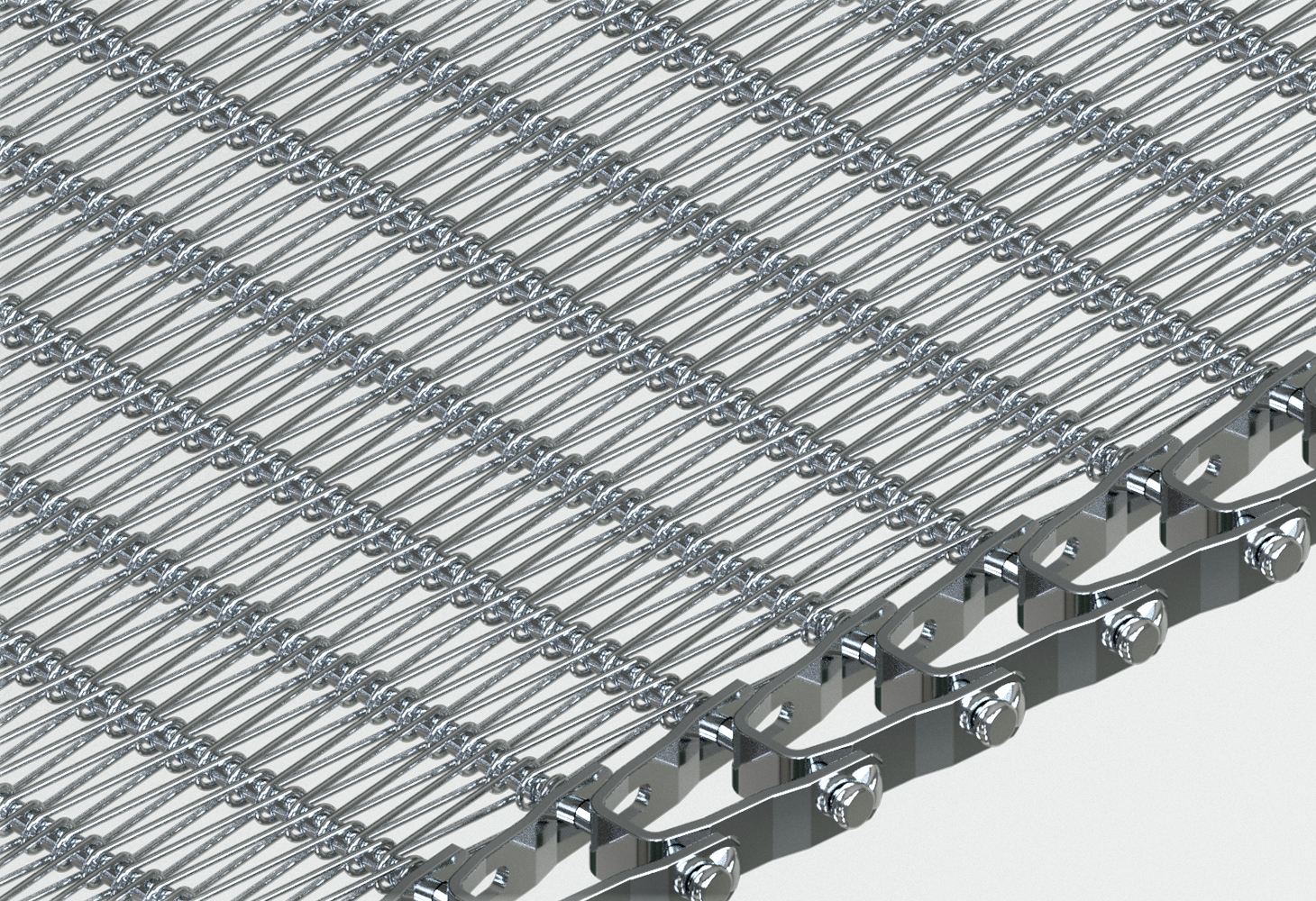

Conveyor belts for spiral pasteurisation towers

Products are generally pasteurised inside spiral towers. Spiral towers use all the necessary vertical space to guarantee that foods pass through the pasteurisation unit for the correct length of time. Spiral towers are usually single or double and can have different set-ups to adapt to existing production processes and to the available space.

The foods to be pasteurised are moved inside pasteurisation units on a conveyor belt that rotates helicoidally around a central drum. The product is pasteurised while moving inside the tower.

The distinctive characteristics of the Costacurta conveyor belts for spiral towers are:

- High quality welding

- Wide range of pitches and turn radii

- Smooth and uniform surfaces to handle the product correctly

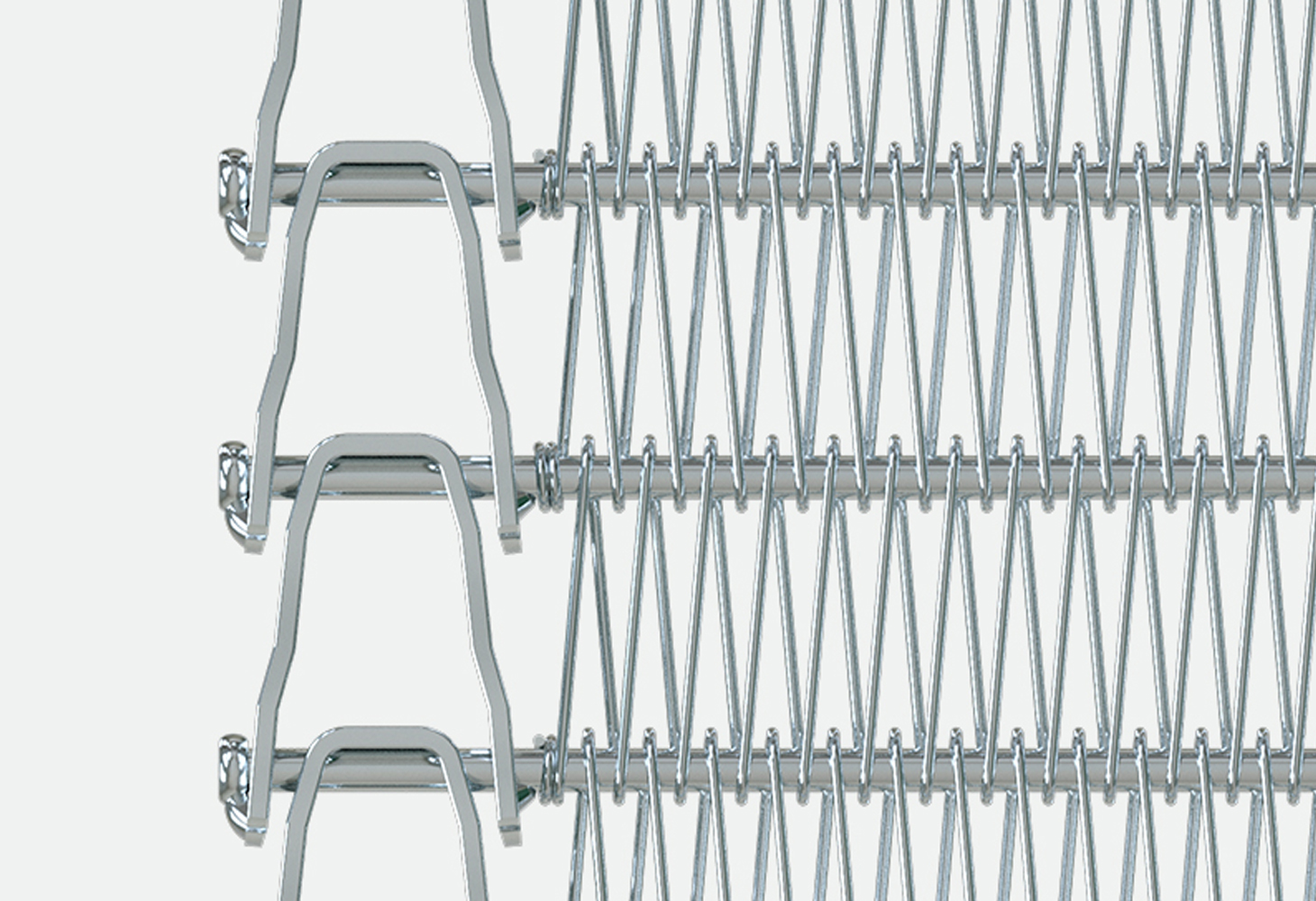

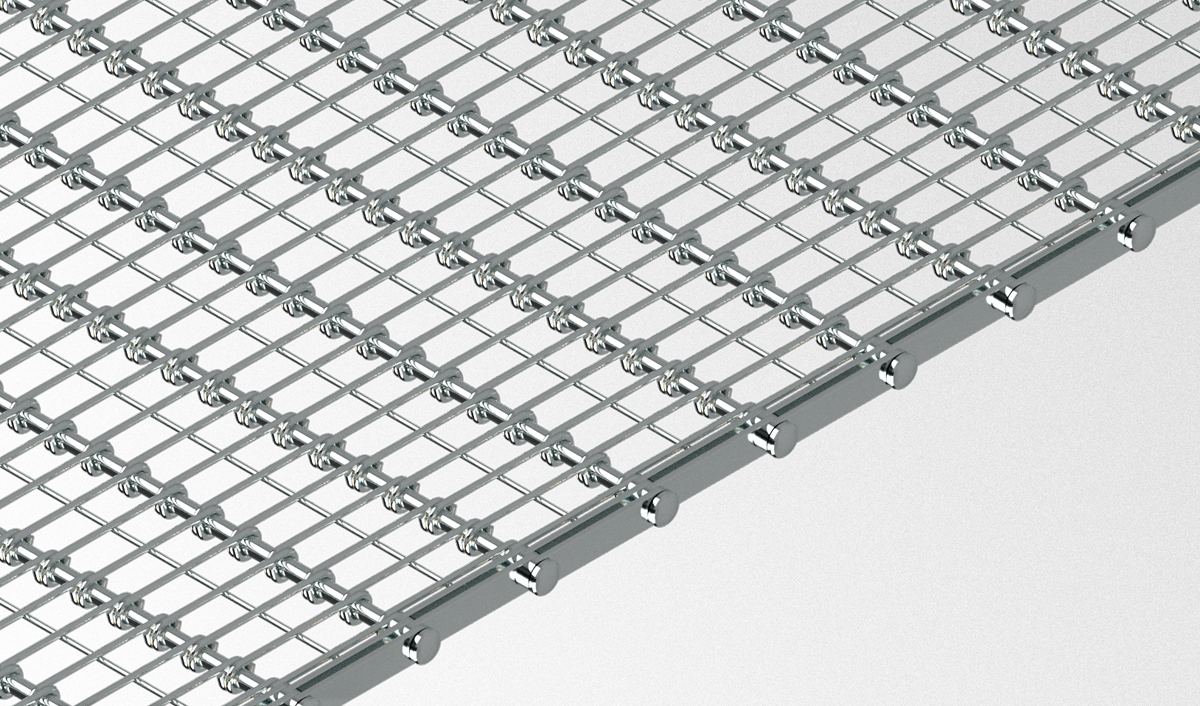

Conveyor belts for straight pasteurisation tunnels

Pasteurisation can take place in continuous tunnels or continuous pasteurisers designed by the clients depending on the process and product to be treated.

The products are moved on metal conveyor belts inside these continuous tunnels.

The conveyor belt accompanies the products that are exposed to a source of heat that kills the bacteria and mycotic agents present in the foods, extending the life of the product.

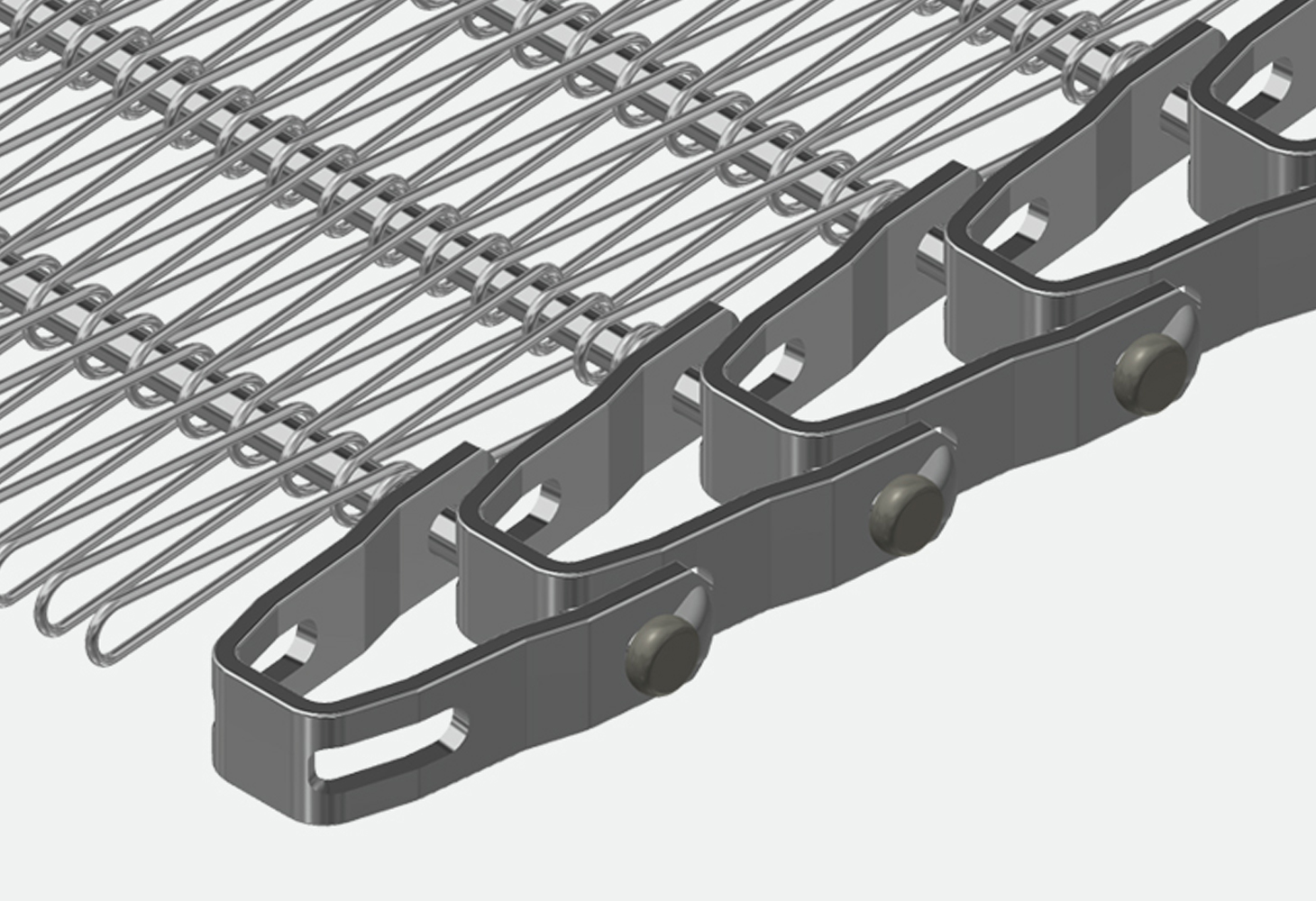

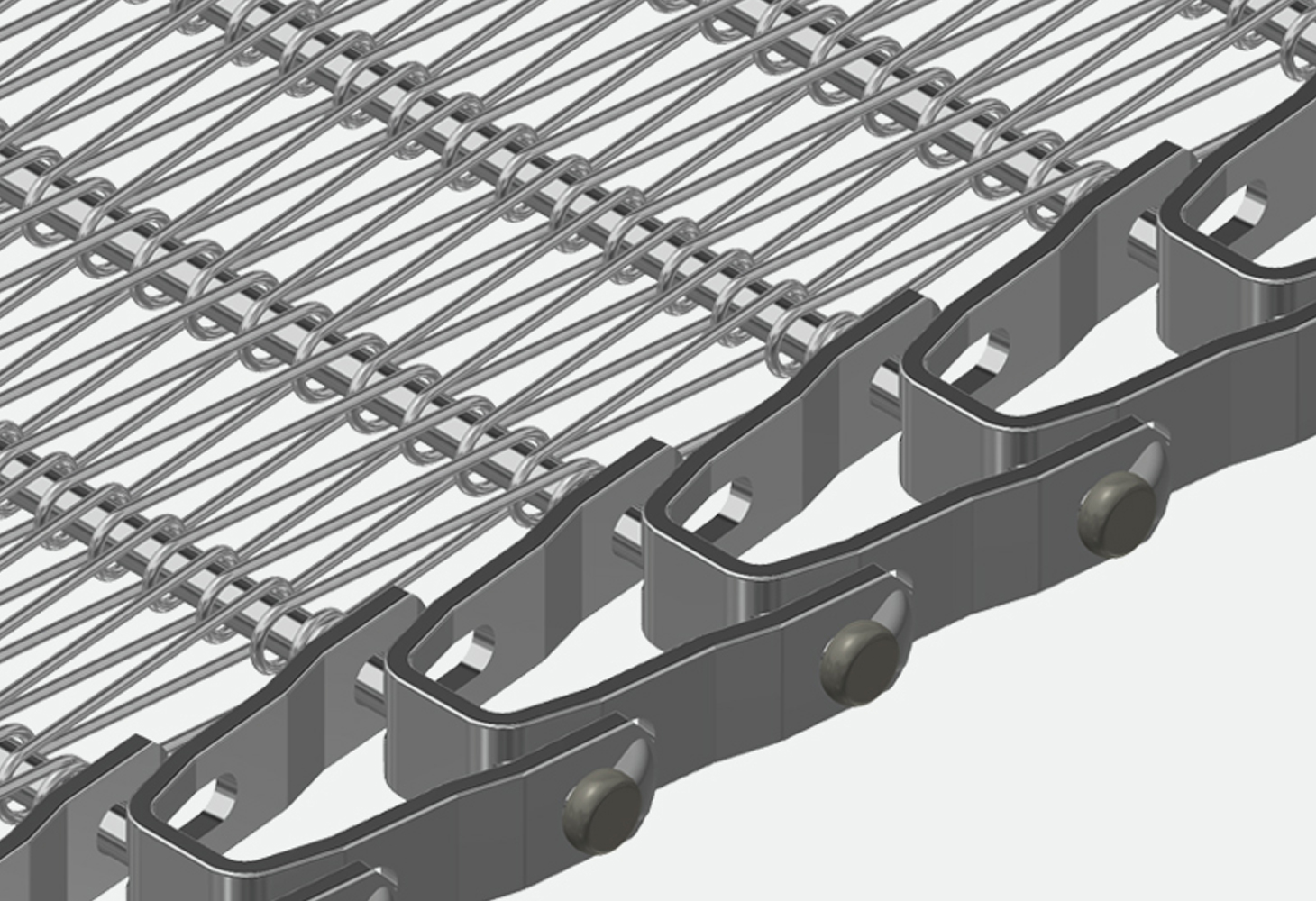

The distinctive characteristics of the Costacurta conveyor belts for pasteurization tunnels are:

- Perfect straightness

- Perfect balance between spirals or shaped flat bars and connecting rods

- Wide range of mesh available

- Smooth and uniform surfaces to handle the product correctly