Costacurta designs and manufactures conveyor belts for freezing spiral towers and straight tunnels used in the food industry. Costacurta’s products are used in different types of freezing systems. Without a doubt, the most common foods are ice cream, pasta, bread, pizza, precooked foods, poultry, meat, fish, fruits and vegetables.

The conveyor belt is selected to facilitate the transport and freezing of the foods, based on the plant layout, operating conditions and characteristics of the product to freeze.

Moreover, the conveyor belts are easy to clean and are made of high-quality materials to guarantee utmost hygiene.

As well as guaranteeing a high-quality product, costacurta provides technicians and engineers to assist clients in the selection of the belts and their installation.

Freezing converts the water present in foods into ice crystals. This process prolongs the life of a food product, maintaining the same nutritional and organoleptic properties as the fresh product. During the freezing process, foodstuffs are rapidly brought to low temperatures. They reach a temperature of between approximately -30°c and -40°c in just a few minutes.

Do you have a specific request?

Contact us now

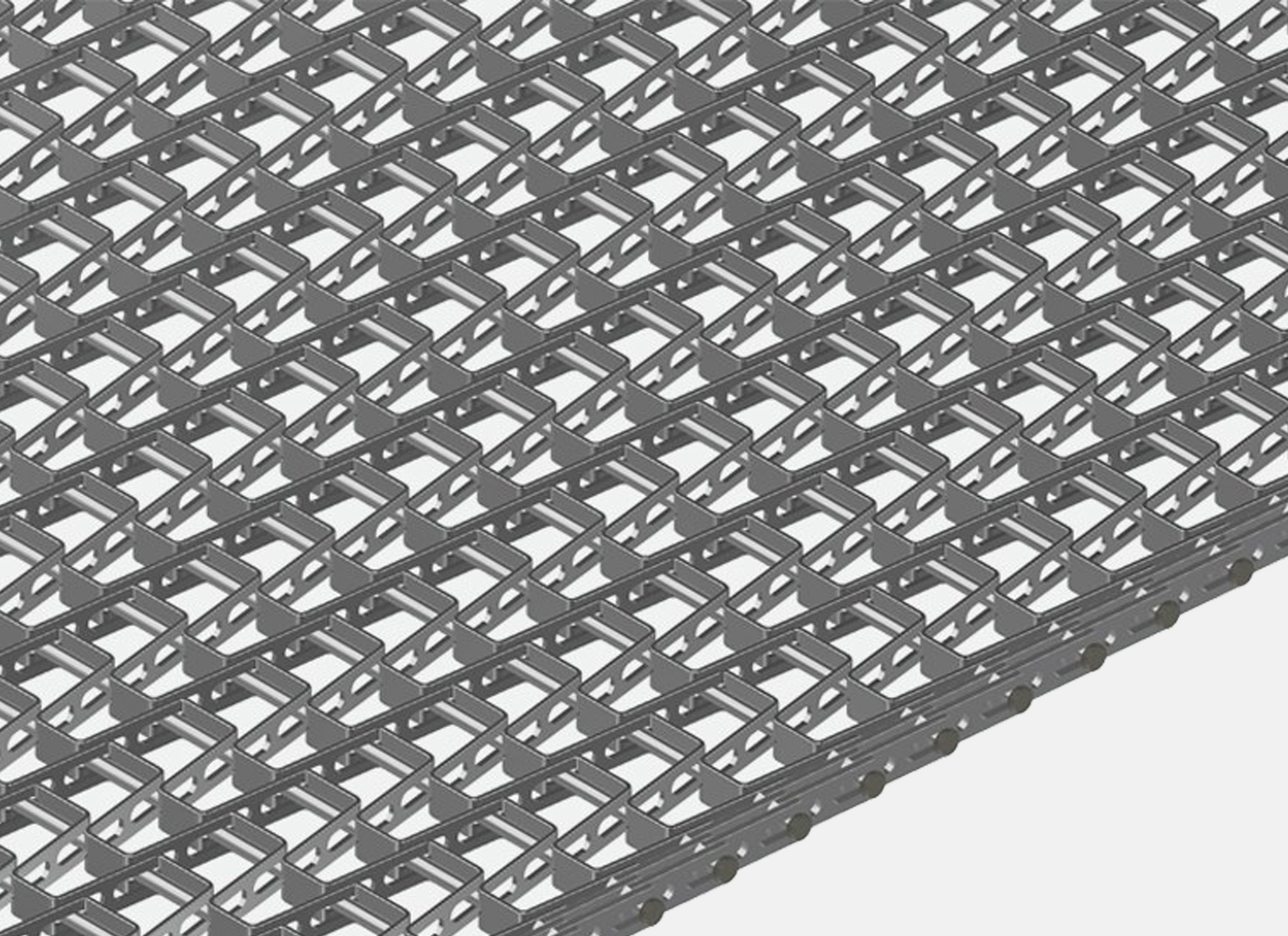

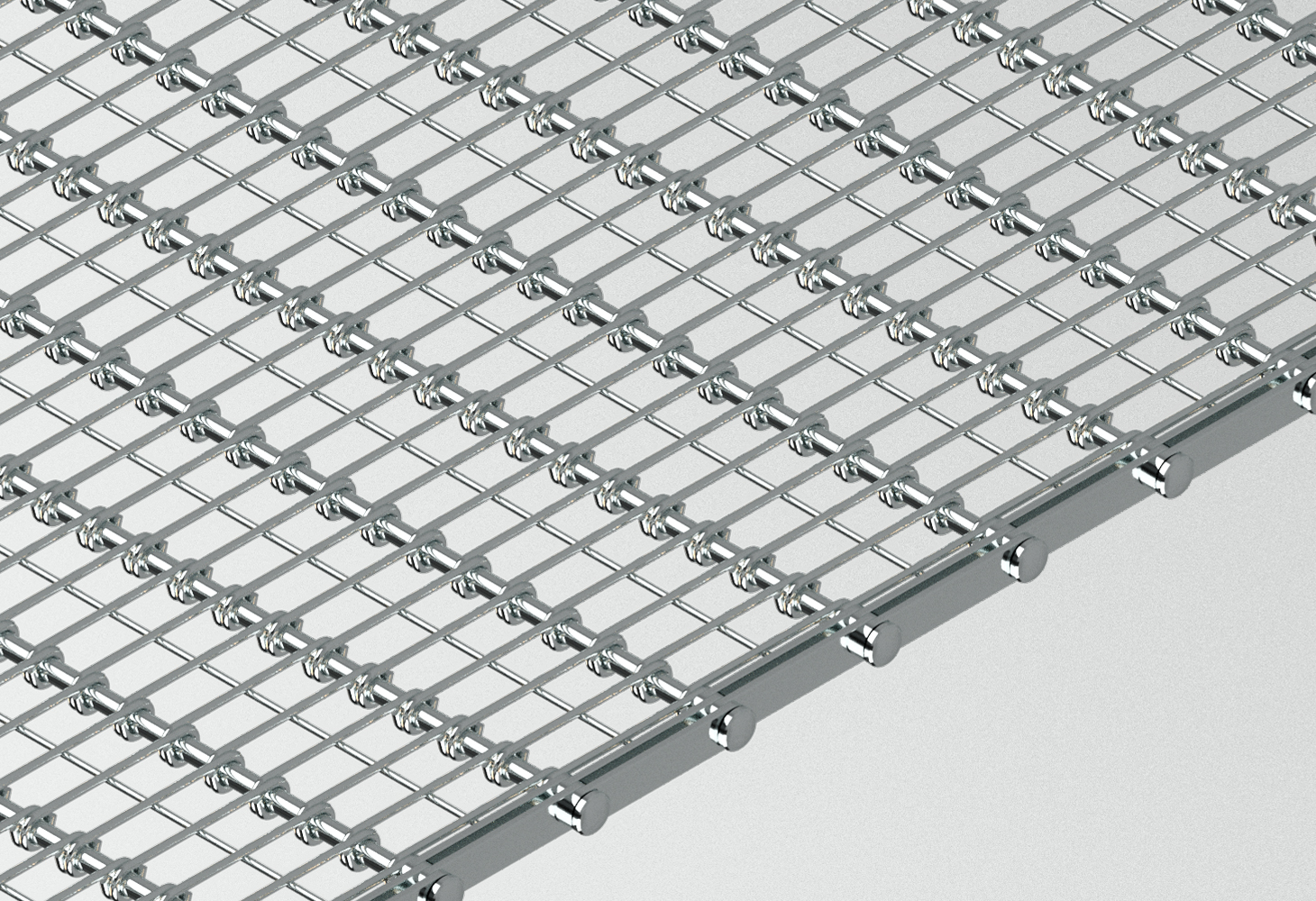

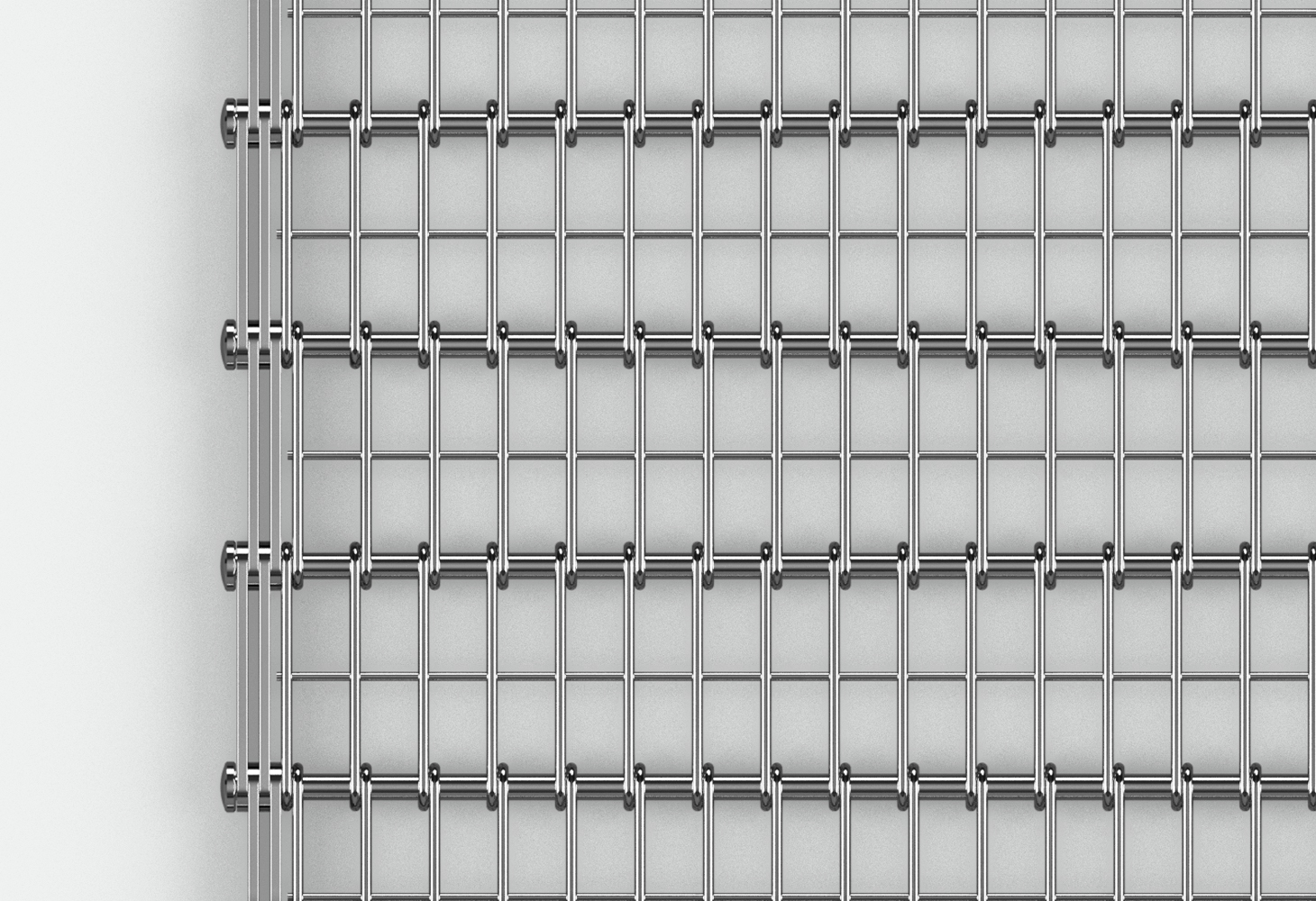

Conveyor belts for straight freezing tunnels

Food can be frozen in continuous tunnels at temperatures of between approximately -30°C and -40°C, depending on the freezing process and the product to be frozen. The products are moved on metal conveyor belts inside these continuous tunnels.

The conveyor belt moves the product that is exposed to a jet of very cold air or coolants that rapidly transform the water contained in the foods into ice.

The distinctive characteristics of the Costacurta conveyor belts for freezing tunnels are:

- Perfect straightness

- Perfect balance between spirals or shaped flat bars and connecting rods

- Wide range of mesh available

- Smooth and uniform surfaces to handle the product correctly

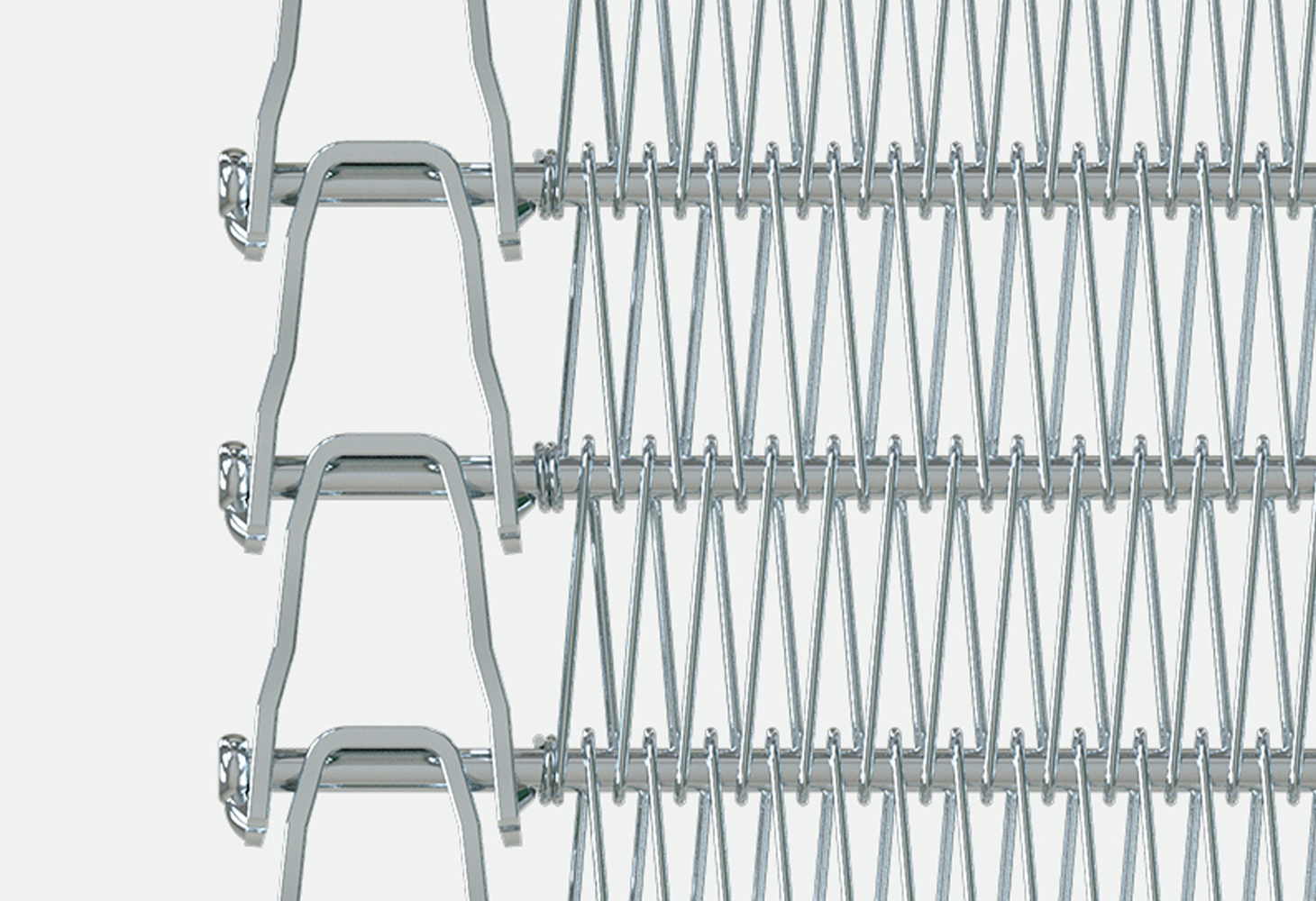

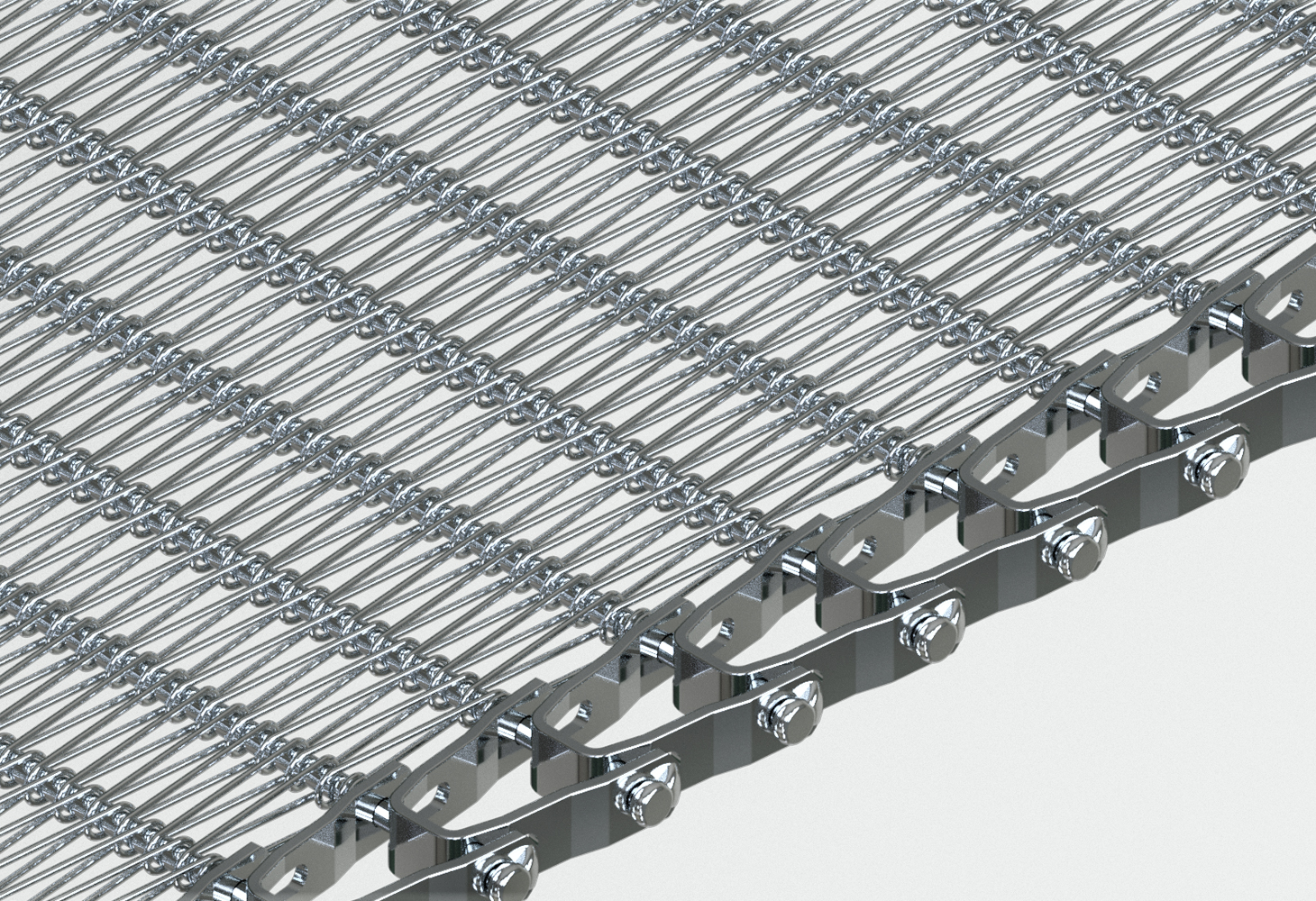

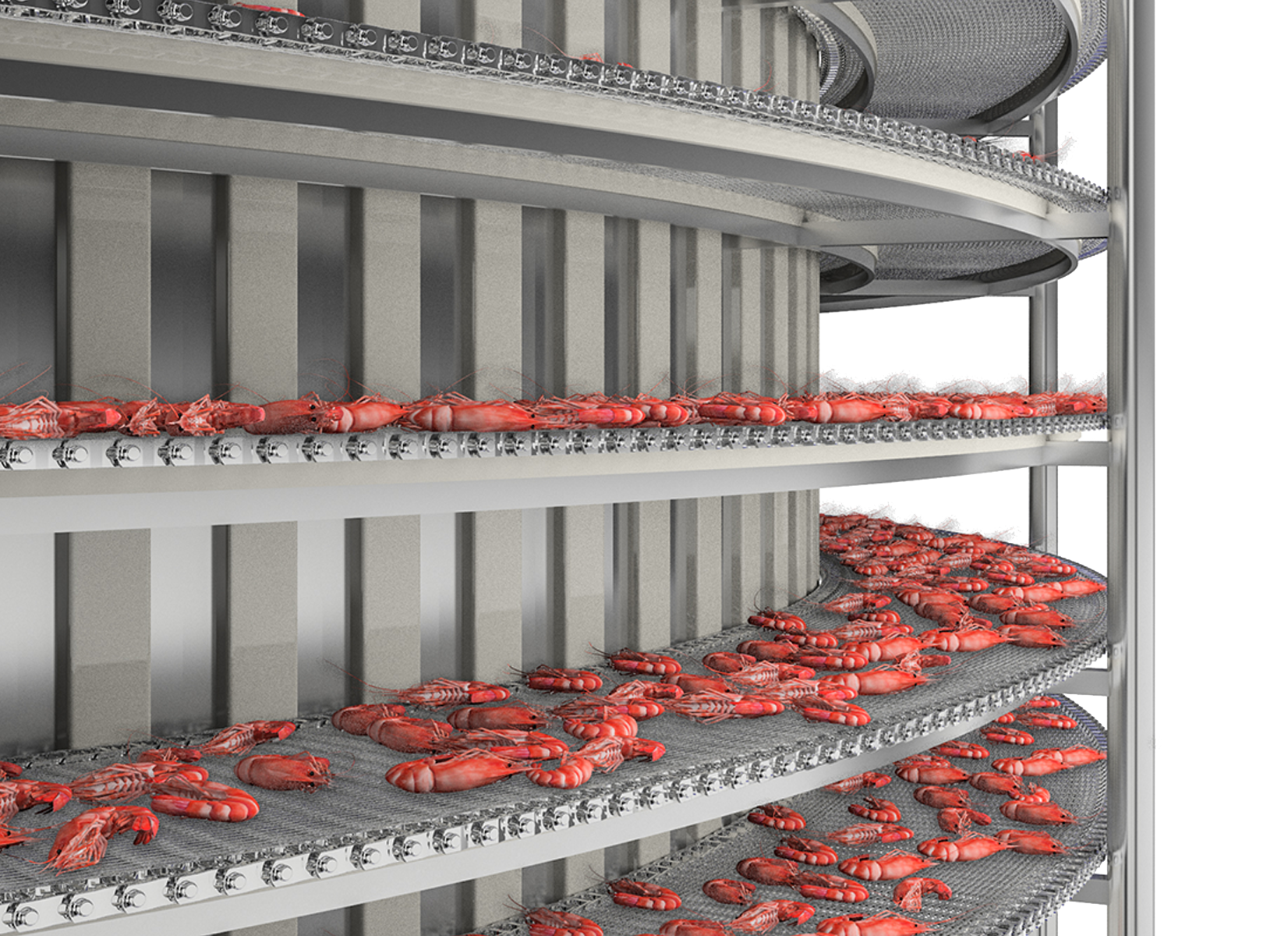

Conveyor belts for spiral freezing towers

The freezing process generally takes place inside spiral towers. Spiral towers use all the necessary vertical space to guarantee that the products remain in the freezing unit for the necessary length of time. Spiral towers are usually single or double and can have different set-ups to adapt to existing production processes and to the available space.

The foods to freeze are moved inside freezing units on a conveyor belt that rotates helicoidally around a central drum. The product is frozen while moving inside the tower.

The distinctive characteristics of the Costacurta conveyor belts for spiral towers are:

- Wide range of pitches and turn radii

- High quality welding

- Smooth and uniform surfaces to handle the product correctly