The choice of the most suitable filtering element for specific operating conditions, its correct dimension and the quality of its construction are essential elements in the filtering and separation stages of water (waste-water and process fluids) and waste (slurries, sludges and digestate for the production of biogas) treatment processes. The wedge wire screens and perforated plates used in screw presses, rotary drums, self-cleaning filters and static screens can therefore be decisive for the efficiency of the machinery and the final result of the process.

Costacurta has been manufacturing a wide range of filtering elements, from wire cloths and meshes to perforated plates and wedge wire screens for over 100 years.

Costacurta’s components comply with the tightest technical specifications and are therefore suitable for highly specific filtration and separation needs, typical of water and waste treatment processes.

Contact us

To receive additional information on wedge wire screens and perforated plates for water treatment and waste processing

Tailor-made filtering elements for water and waste treatment

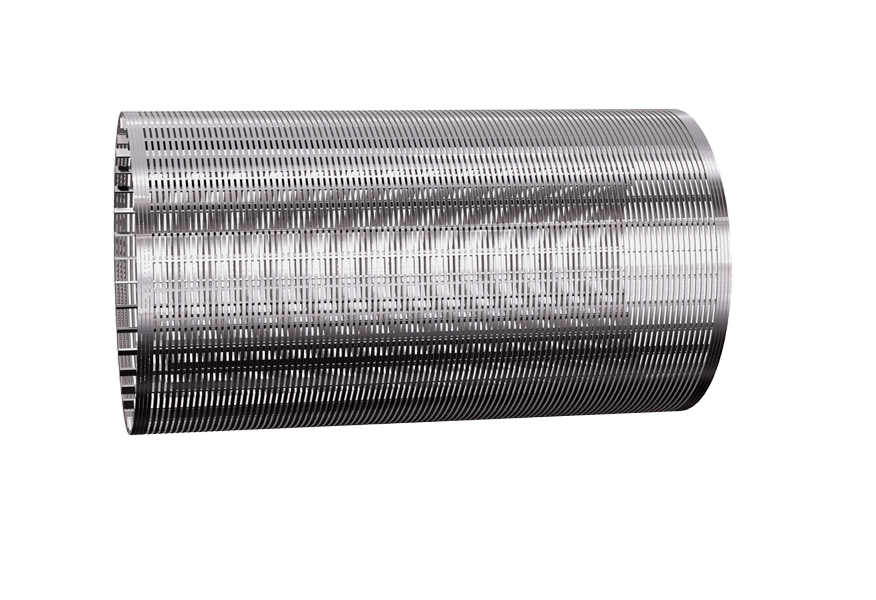

FOTI wedge wire screen cylinders

- Machinery: Rotary drum screen

- Application: Waste water treatment

- Technical specifications: Min. slot opening: 100 μm

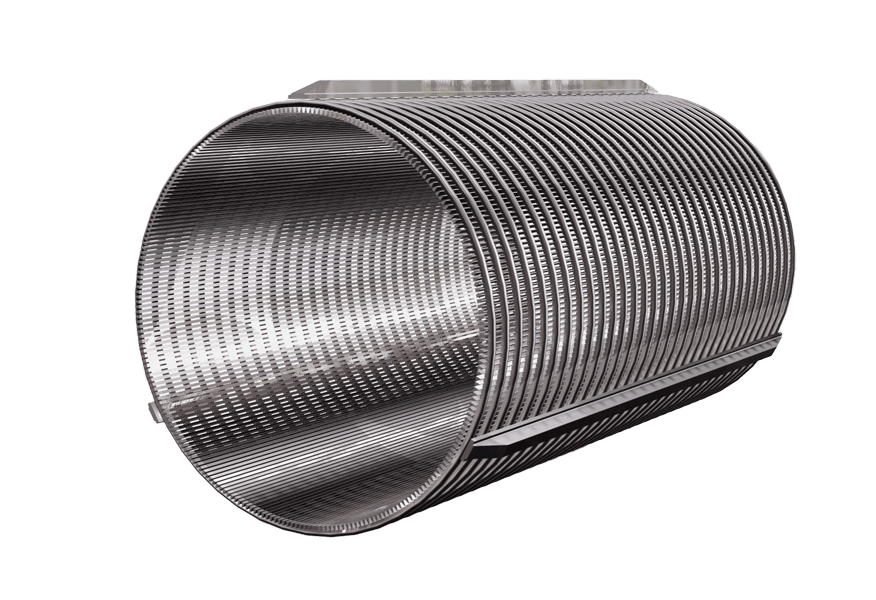

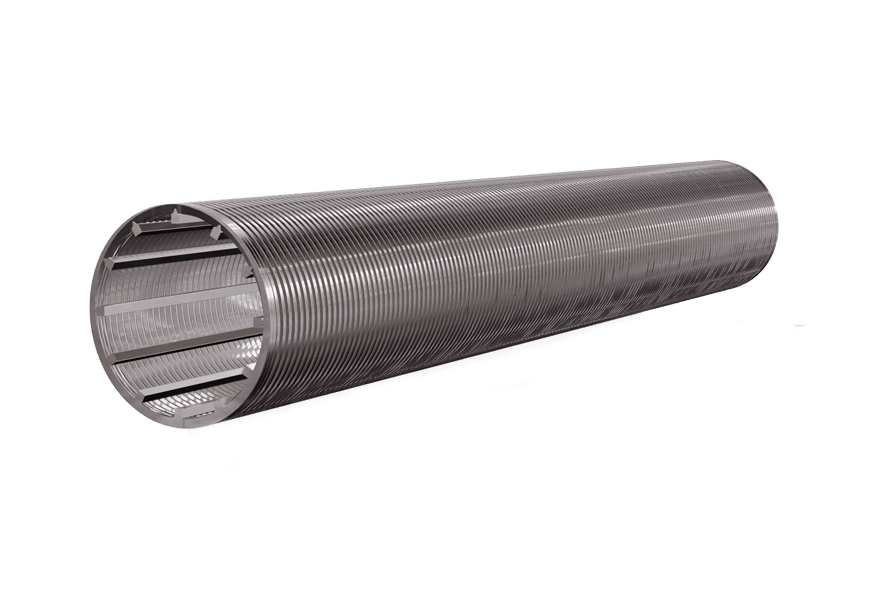

FITO wedge wire screen cylinders

- Machinery: Screw press

- Application: Biogas production, slurry separation and waste processing

- Technical specifications: Min. slot opening: 100 μm

Wedge wire screen filter candles

- Machinery: Self-cleaning filter

- Application: Process fluid treatment

- Technical specifications: Min. slot opening: 40 μm

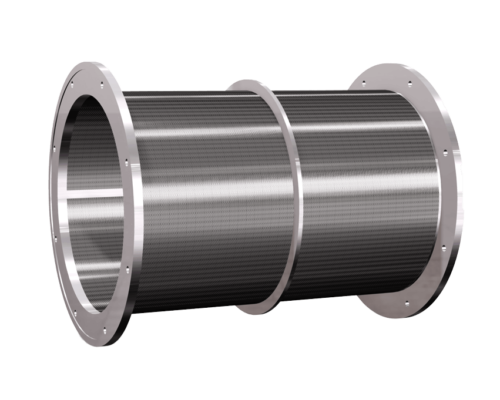

Perforated plate cylinders

- Machinery: Screw press

- Application: Sludge separation

- Technical specifications: Hole diameter: from 1 mm to 6 mm

- Hole section: conical, cylindrical, bi-cylindrical with the possibility of obtaining shaped holes

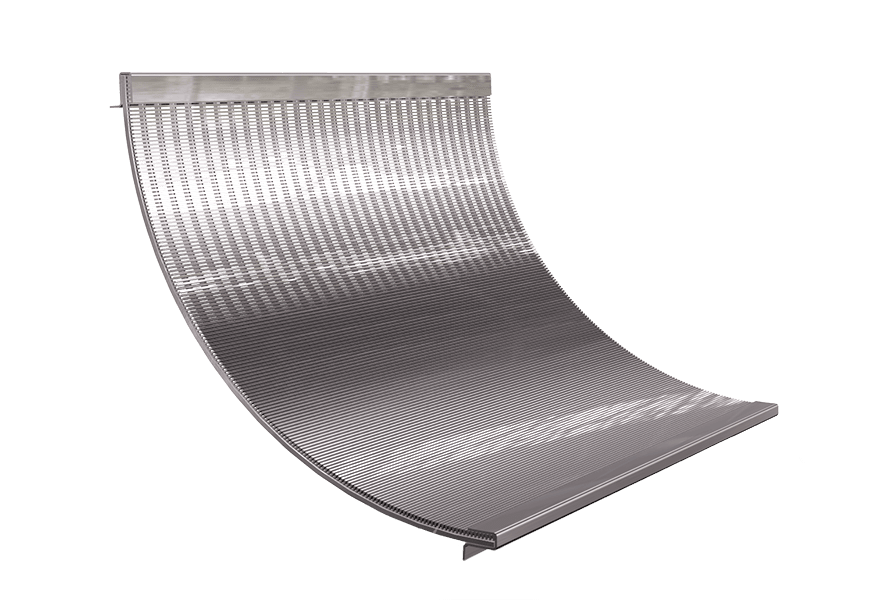

Wedge wire screen curved and flat panels

- Machinery: Static screen and sieve bend

- Application: Water and starch treatment

- Technical specifications: Profile wires: from 0.51 x 1.20 mm to 3.30 x 6.35 mm

The wedge wire screens and perforated plates can be personalized not only in terms of the size of the holes and the openings but also as regards the materials and finishes.

Download the technical presentation

Flexible production and strict quality controls

The high quality of Costacurta’s filtering elements depends on a number of factors including the choice of raw material. The materials and sizes of the wires and plates are chosen to meet the customer’s specific needs. The chemical and mechanical properties of the materials used are closely monitored and checked.

Production is characterized by a high level of automation, the experience and skills of the operators and constant quality controls both during production and on the finished product using laser, mechanical and optical instruments.

Tailor-made services

Costacurta provides tailor-made services also for orders of small quantities and dimensions.

Product development and consultancy

Thanks to its long-standing experience in the production of a wide range of filtering elements (wire cloths and meshes, perforated plates and wedge wire screens), Costacurta is able to help clients choose the best filtering element for their process and performance needs and, if required, to develop specific components able to meet highly specific filtering and separation needs in accordance with strict dimensional tolerances.

Project management

The sales&project managers accompany clients throughout the project: from the request for a quotation to the selection of the component, its construction and installation, and after-sales support.

Flexibility

The company can fulfil specific requests, including orders of small quantities, guaranteeing a high service level thanks to the stock of plates and wires in different materials and dimensions.

Stock Agreements

When requested, Costacurta can keep a stock of finished products in quantities agreed on with the client that that can be collected when needed.

To receive additional information on wedge wire screens and perforated plates for water treatment and waste processing