Inlet distributors are installed on feed inlet nozzles of horizontal or vertical separators, to allow uniform distribution of fluids inside the separators and to perform a primary gross separation of dispersed phases.

Inlet distributors can be designed and made in various configurations and designs, depending on the process specifications, the fluids to separate and the inlet momentum.

Do you have a specific request?

Contact us nowINLET DISTRIBUTORS ARE AVAILABLE IN THE FOLLOWING VERSIONS

Slotted or perforated pipe

These are inlet distributors comprising a slotted or perforated pipe. They are used in the separation of liquid phases, to obtain uniform distribution of the liquid flow velocity through the separators, promoting a primary gross separation by means of decantation and optimal functioning of the specific internals for liquid-liquid separation.

Half open pipe

These inlet distributors consist of a half-open pipe. They are used at gas-liquid separator inlets when the inlet momentum is slow and the process conditions are such as to allow gross separation between the 2 inlet phases be means of simple gravity.

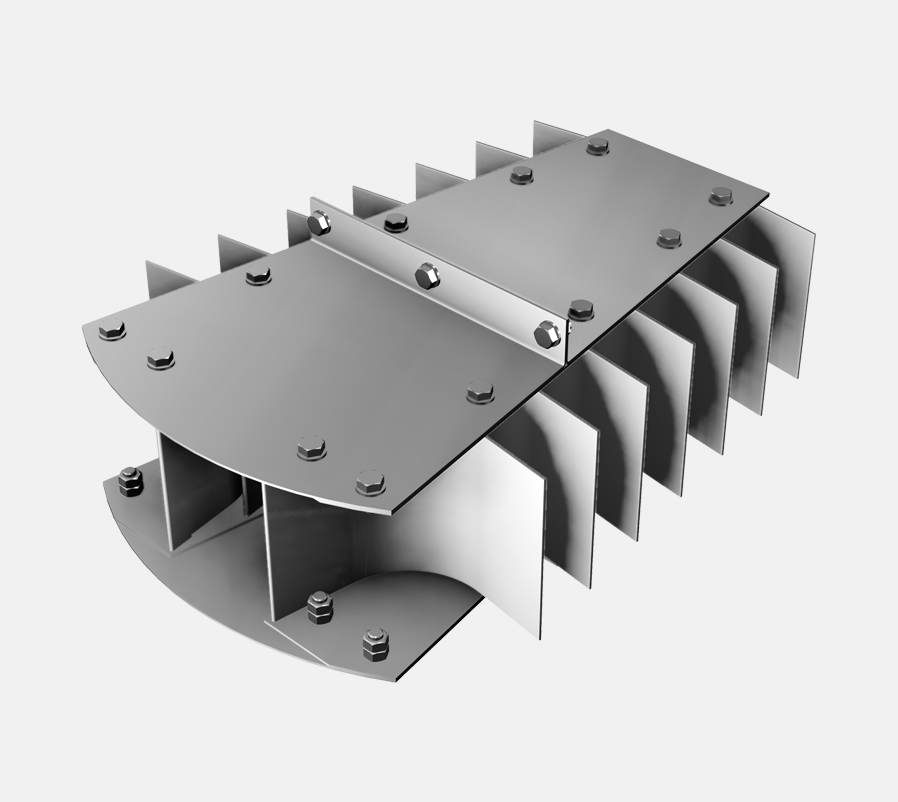

Vane feed inlet

This inlet distributor, commonly known as Schoepentoeter, is characterised by a vane structure that makes it suitable for two-phase and three-phase separators in the presence of high inlet momentum, high gas flow rates and pressures. The position and shape of the vanes promotes uniform distribution of the gas in the separator and separates most of the liquid phases from the gas ones.

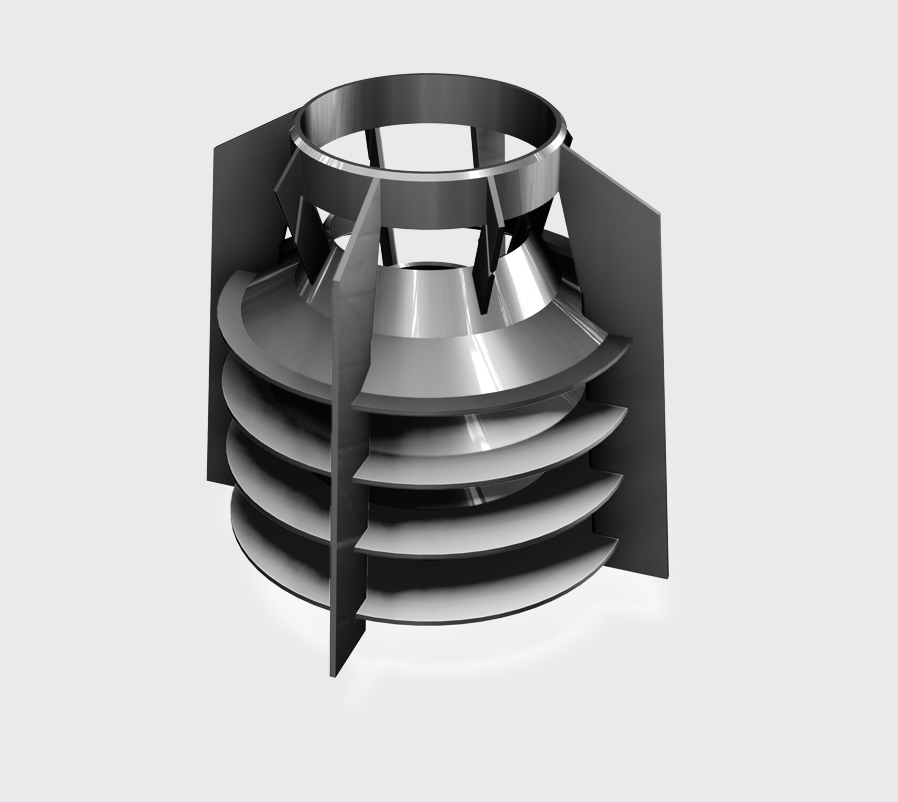

Cyclonic inlet

Cyclonic inlet distributors are made of a series of cyclones in which the inlet flow is distributed and which, exploiting the centrifugal force, perform a primary separation of the gas phases from the liquid phases, eliminating the foam and preventing the formation of emulsions. Their structure makes them ideal for gas-liquid and gas-liquid-liquid separation in the presence of high volumes of liquid phases and high inlet momentum (e.g. test separators or production separators).

VICO-Radial

The radial distributor allows 360° distribution of the inlet flow, immediately reducing velocity and turbulence, promoting de-mixing of the gas and liquid phases at the inlet and optimising gross separation through gravity. It is an excellent solution for applications in which momentum on inlet is very high and to increase the flow rates that can be treated in existing separators.

Custom made distributor

Besides the configurations described above, Costacurta, supported by the expertise and experience of its Separation Technologies department, is able to design and develop new distribution solutions to meet its clients’ requests or in critical operating conditions.

Distinctive elements

Wide range of designs and solutions

In-house process design by a dedicated team

High quality and precision of the product

MATERIALS

Stainless steels

Special alloys (Monel, Inconel, Incoloy e Hastelloy)