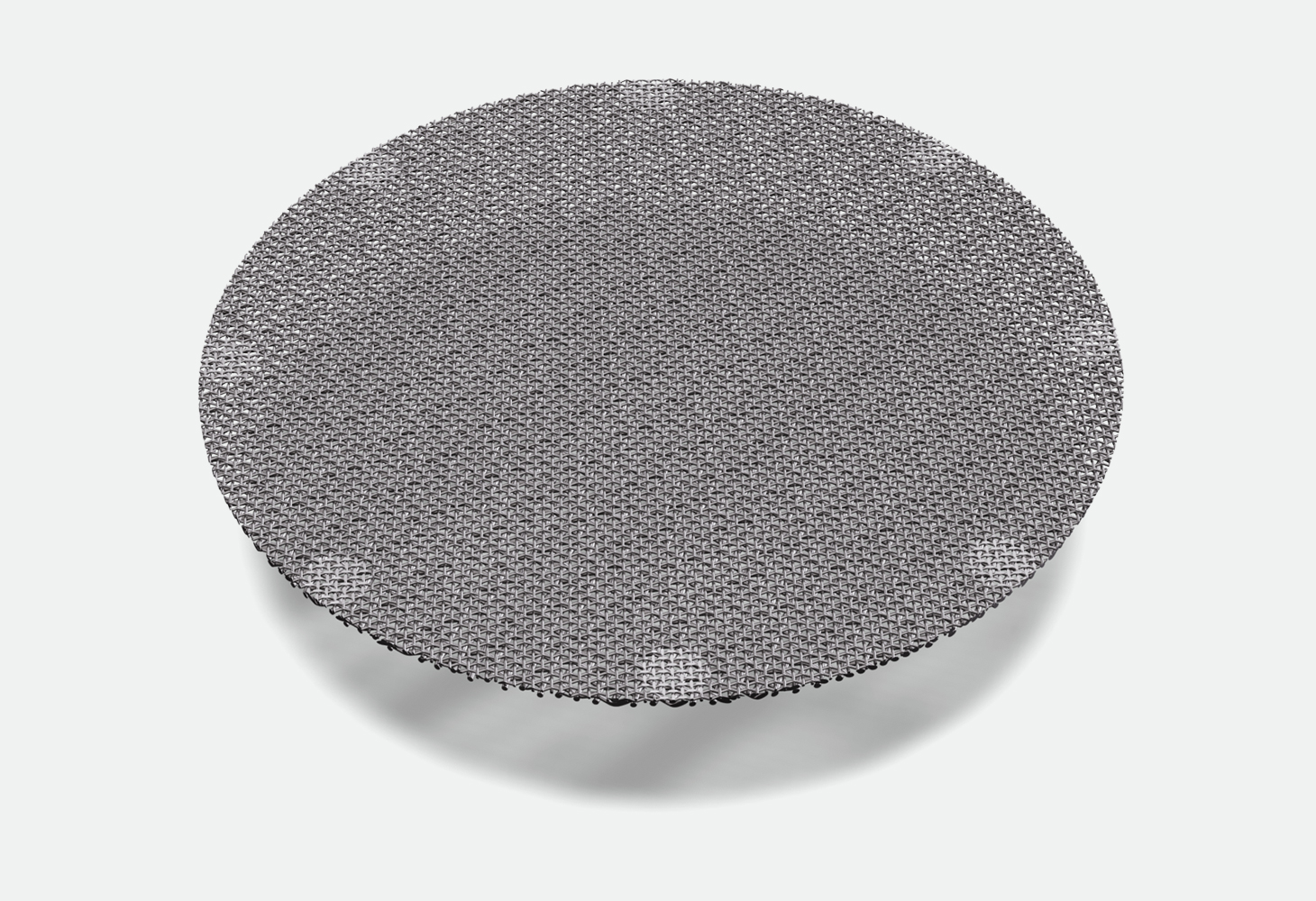

Spot-welded filters are always made from several wire cloths in sequence, spot welded together. For these filtering discs the number and characteristics of each wire cloth, their sequence and the number of spot welds must be defined. Before punching, the wire cloths are tested and stabilised.

Do you have a specific request?

Contact us now

Materials

The wire cloths used for the filtering discs can be made from any metal and alloy that can be drawn into wire; however, the ones normally used and generally available in stock are in carbon steel or in AISI 304 or 316 stainless steel.

Supply

After assembly and spot welding, the filtering discs are ultrasonic cleaned and packed in standard or special vacuum packs.

Use

The main application of these products is on spinning machines heads for the extrusion of plastics, synthetic fibres and other polymers; however, they are also used for the extrusion of rubber sheaths for electric cable compounds.

DISCOVER THE OTHER FILTERING DISCS