Costacurta produces high-quality perforated plates for waste treatment. More specifically, it manufactures and supplies drilled plates installed in friction washers used during the plastic waste washing stage.

Recycling of plastics is a specific waste recycling sector and consists of a series of operations to transform waste plastic material into a new product that can be used in numerous production processes.

After the separated waste collection stage, the plastic is transported to recycling plants, where it is subjected to selection, reduction or cutting and washing.

The plastic waste is then separated from any other excess materials, processed and reduced to pellets for their distribution.

Do you have a specific request?

Contact us now

Drilled plates for friction washers

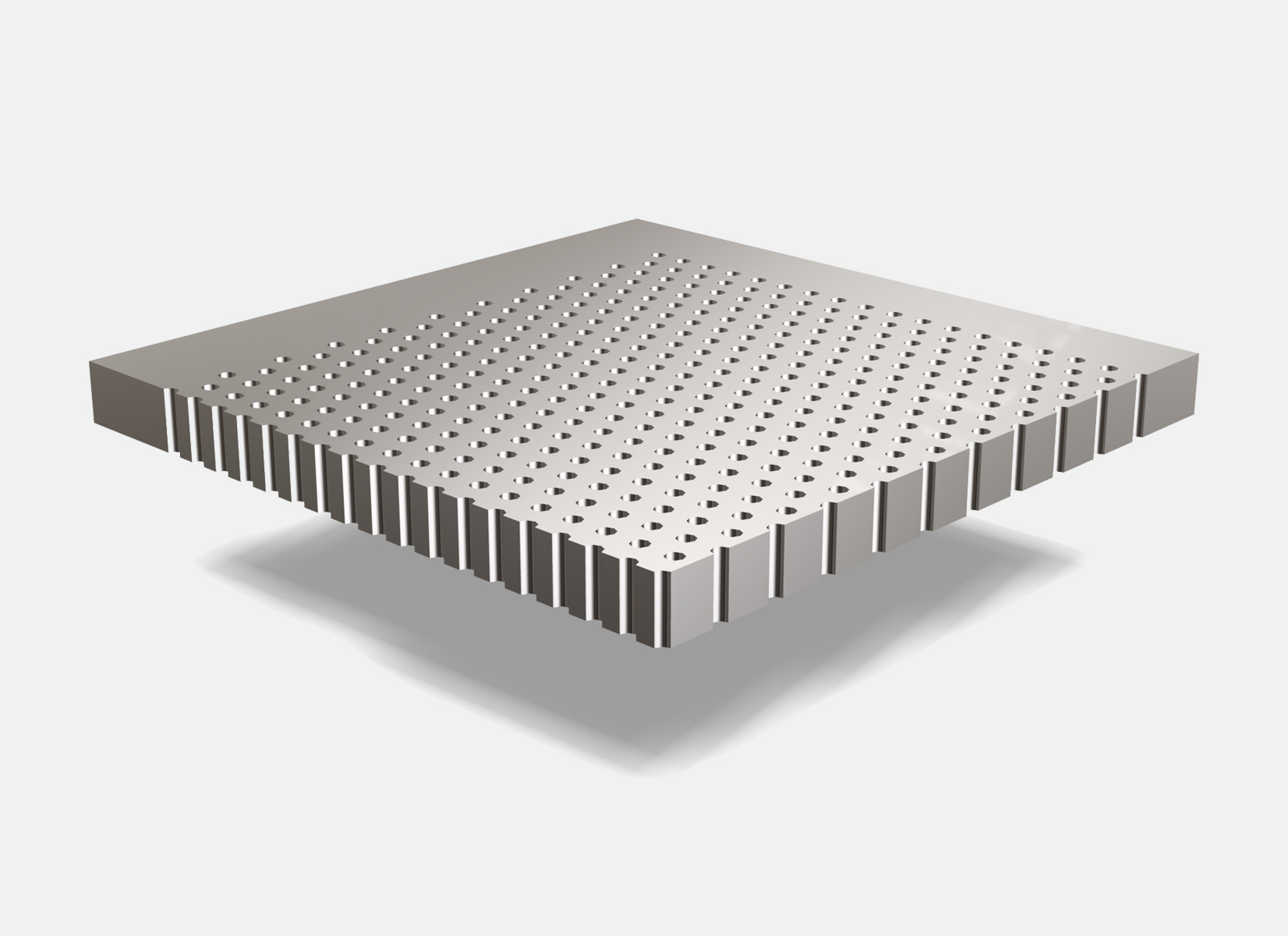

Perforated plates realised by Costacurta are installed in machines commonly referred to as friction washers, used for washing plastic waste.

The friction washer is used to wash films of plastic waste, like flakes of pet bottles and other types of solid plastic materials, with a high level of contamination or persistent dirt and dimensions usually of more than 2-3 mm.

The machine consists of a drilled plate, suitably bent to form an hexagonal prism, and some nozzles to facilitate cleaning the plastic waste.

The oily residue and dirt flow through the holes in the machine, while the plastic fragments are then transferred for the treatment and recycling operations.

The distinctive characteristics of the Costacurta perforated plates for these machines:

- High quality and precision of the drilling, which is carried out using cutting-edge machines and technology

- High quality of the material used