Costacurta designs and manufactures straight conveyor belts used in rayon fibre washing tunnels.

Rayon is a textile fibre obtained using chemical and mechanical processes that transform cellulose into filaments.

The raw material used in rayon production is normally wood cellulose. The production process consists of transforming cellulose into viscose. This takes place by treating it with chemical compounds. The viscose is then filtered and drawn to produce filaments. These filaments are joined together in threads and washed repeatedly, bleached, dried and packed.

Do you have a specific request?

Contact us now

Conveyor belts for rayon washing tunnels

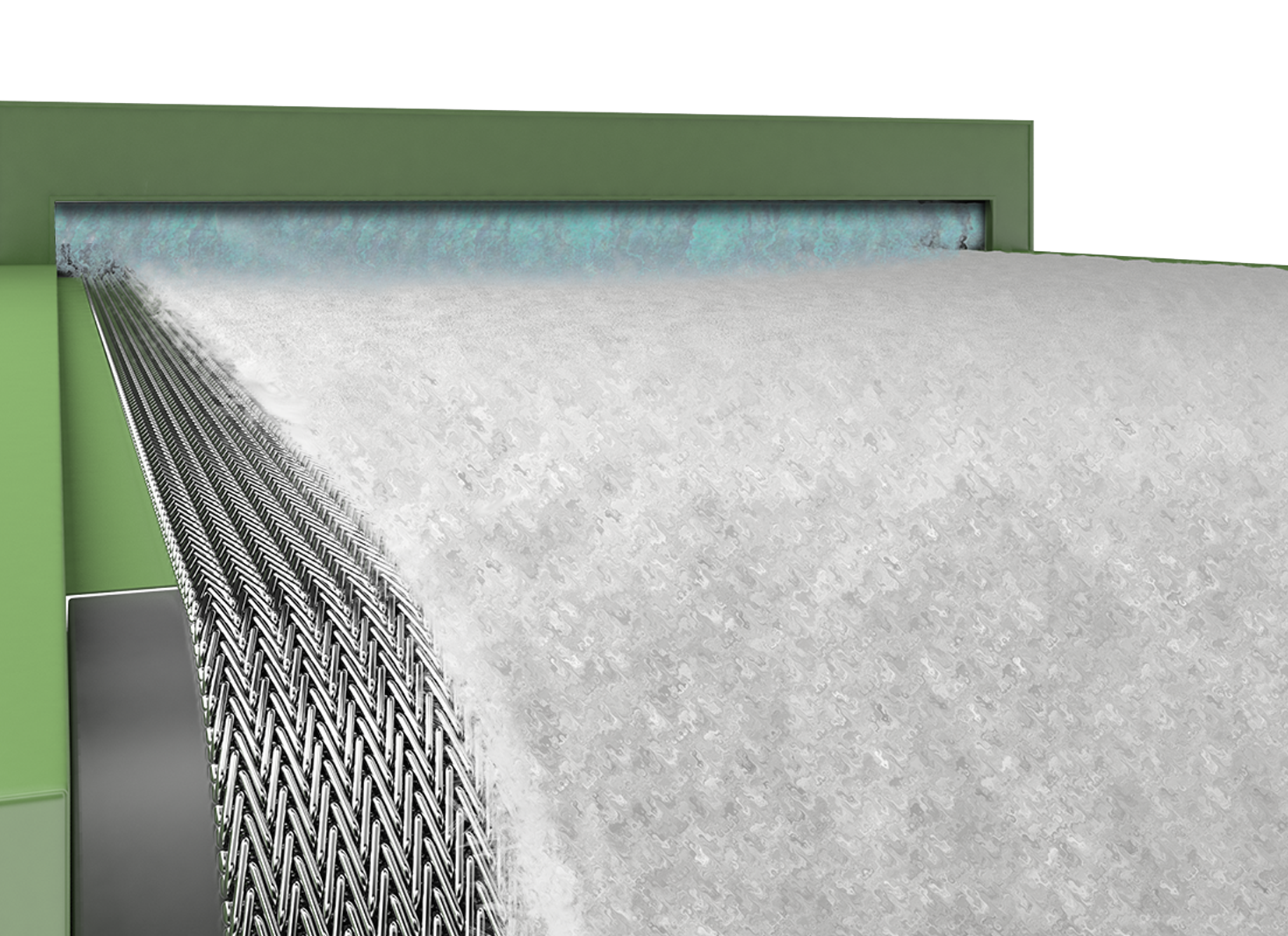

Costacurta conveyor belts are used in the washing process (rayon washing tunnels). The quality of the conveyor belt is important to allow correct washing of the yarns and guarantee higher quality of the rayon.

The conveyor belt supports the fibre while it is subject to washing treatments to remove the chemical compounds deriving from previous production phases.

The product, after being suitably rinsed, is transported to the following drying stage.

It is important that the chemical compounds used in viscose production are rinsed well. The materials used to make these conveyor belts are normally Inox 316L stainless steel (W. Nr. 1.4404), Inox 317L (W. Nr. 1.4438) and Inox 317LMN (W. Nr. 1.4439).

Distinctive characteristics of the Costacurta conveyor belts for rayon washing tunnels:

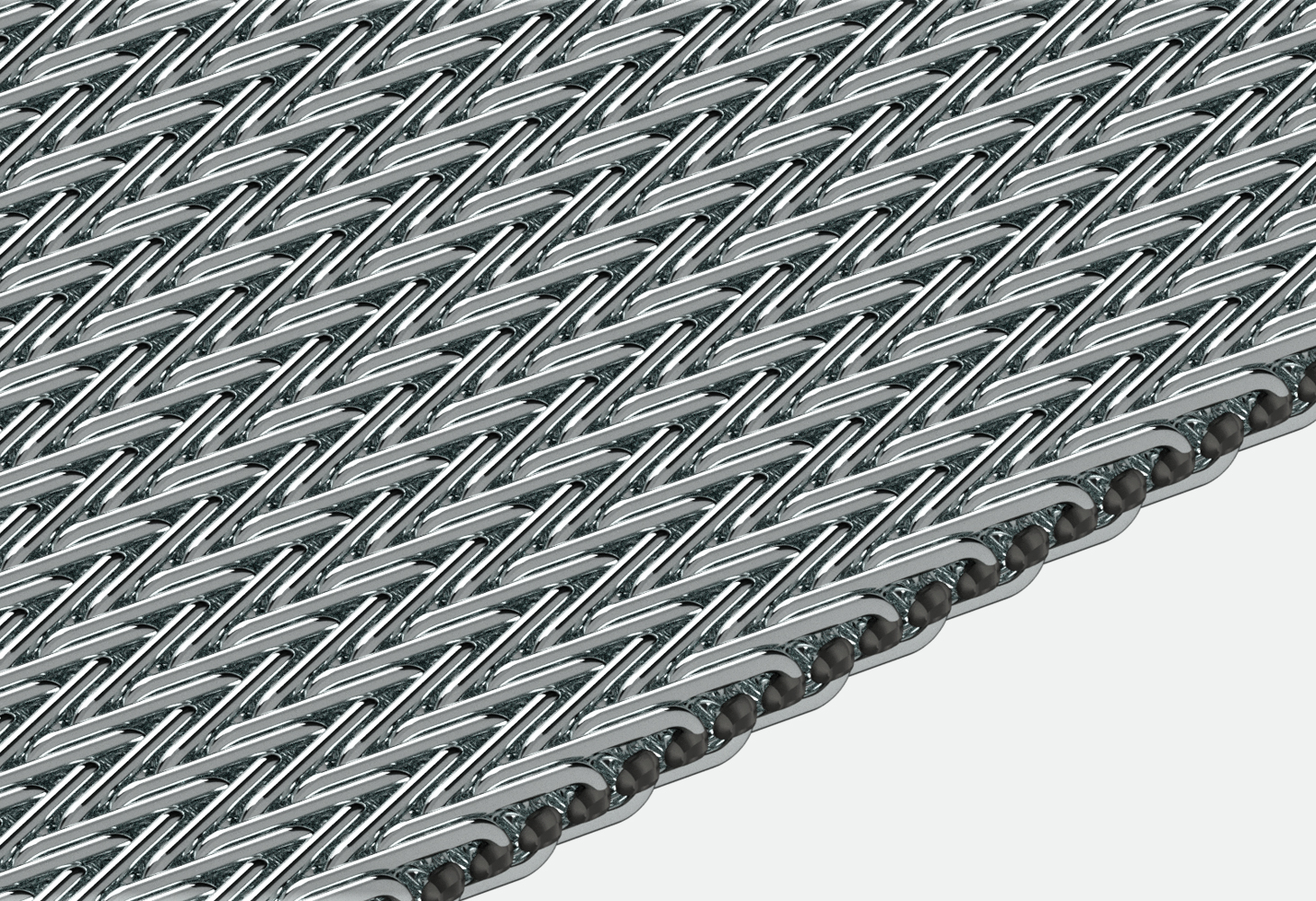

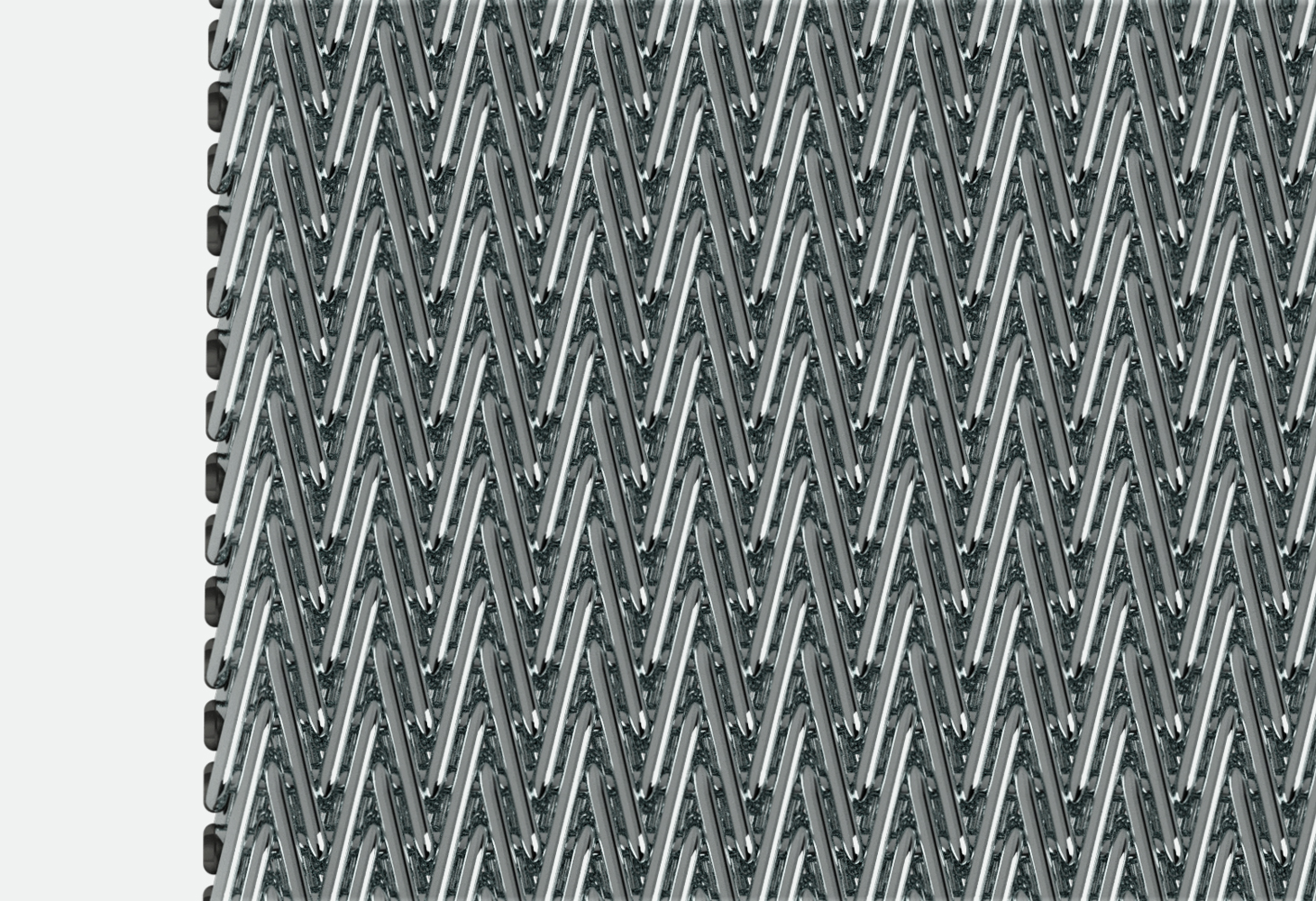

- Extremely smooth and uniform surfaces to prevent the fibres from sticking to the conveyor belt.

- Perfect straightness

- Perfect balance between spirals and connecting rods

- Use of high-quality raw materials and high resistance to corrosion and elongation