When the paper to recycle arrives at the paper mill, it is chopped, bleached and reduced to a pulp by adding hot water. This allows removal of any remaining impurities and waste from the mixture. The remaining fibres dissolved in the water are then filtered several more times to make it suitable for paper production.

Screw press for paper recycling

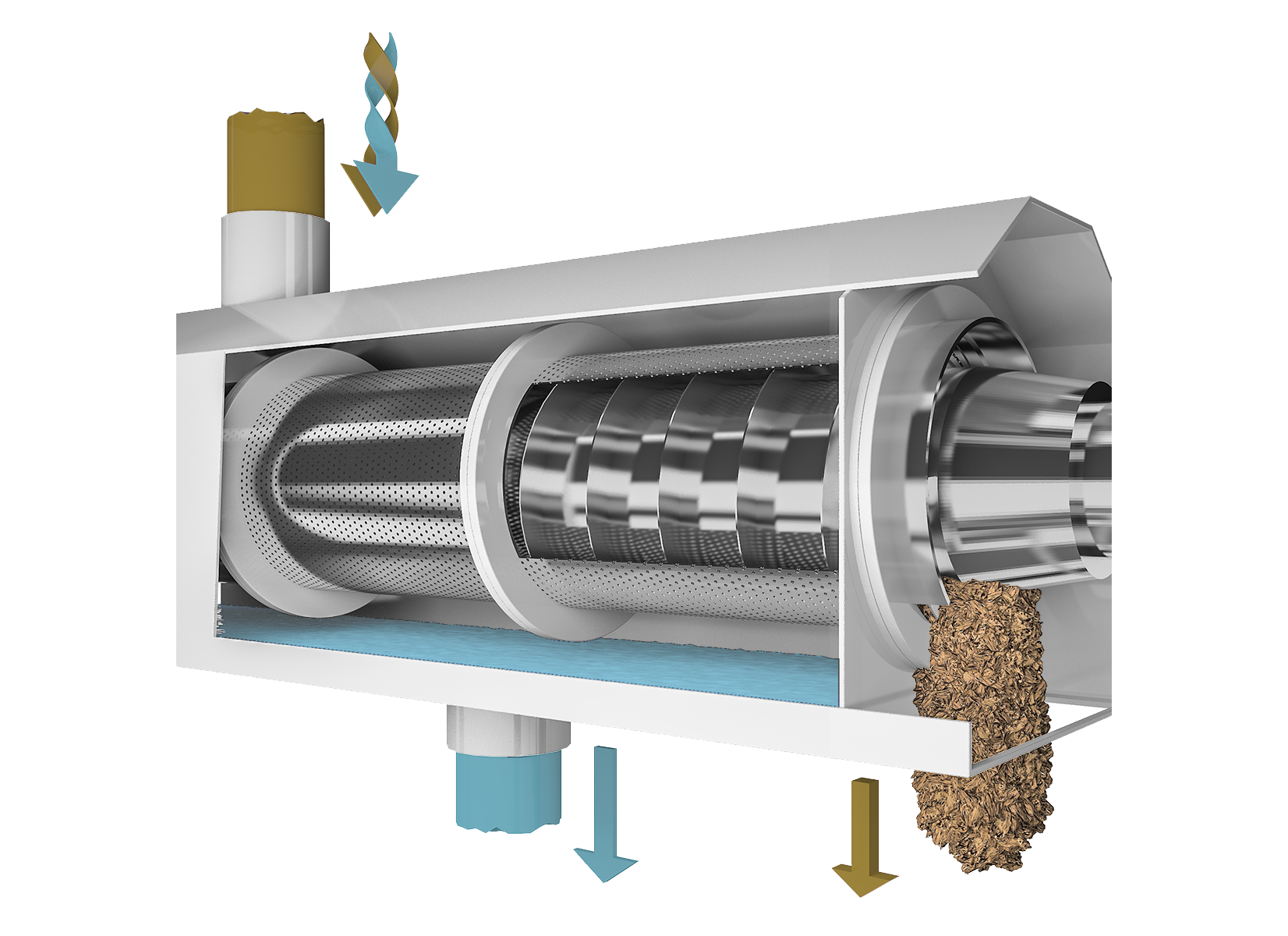

The filtration phase involves the separation of liquids from solids by pressing, which takes place inside a screw press. The screw press is a slow-moving machine in which a conical screw rotates inside a perforated cylindrical filter. The solution of fibres dissolved in water is fed into the press. During the pressing phase, the paper fibre is pressed with increasing force against the metal filter and the holes in the filter allow the water to drain out, retaining the paper pulp.

Paper recycling can transform approximately 95% of the collected material (fibre from waste paper) into new paper.

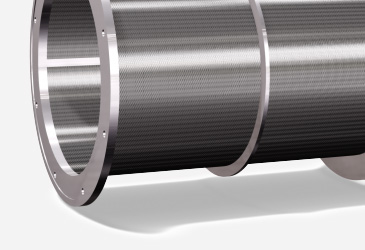

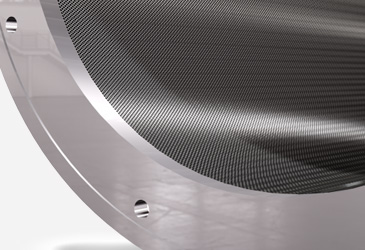

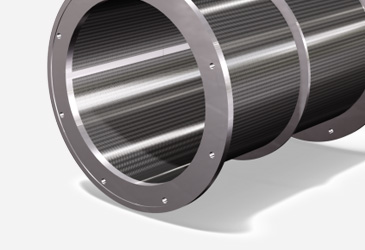

The Costacurta drilled plate used in the filter of the screw press is a fundamental part of the machine. The plate must be sufficiently thick to resist pressure, and have different perforation types (cylindrical, conical and step drilled) to allow filtration of the water and its separation from the solid pulp.

Distinctive characteristics of Costacurta’s drilled plate for screw presses:

- High quality and precision of the drilling

- High quality of the material used