Costacurta designs and manufactures conveyor belts for installation in continuous ovens for enamelling and teflon coating.

Enamelling means coating a steel, aluminium or cast iron surface with enamel. The main aim of enamelling is to protect the object and give it colour and shine. After pre-treatment, the object is enamelled and exposed to a source of heat. The temperature varies depending on the type of enamel used.

Teflon coating means coating a metal surface with teflon. Teflon is sprayed like paint onto the surface to be treated. The teflon-coated materials are then baked in continuous ovens. Teflon coating makes surfaces non-stick and resistant to wear, heat and chemical agents.

Enamelling and teflon coating processes can be applied to many products. The most well–known application is undoubtedly that of saucepans.

Do you have a specific request?

Contact us now

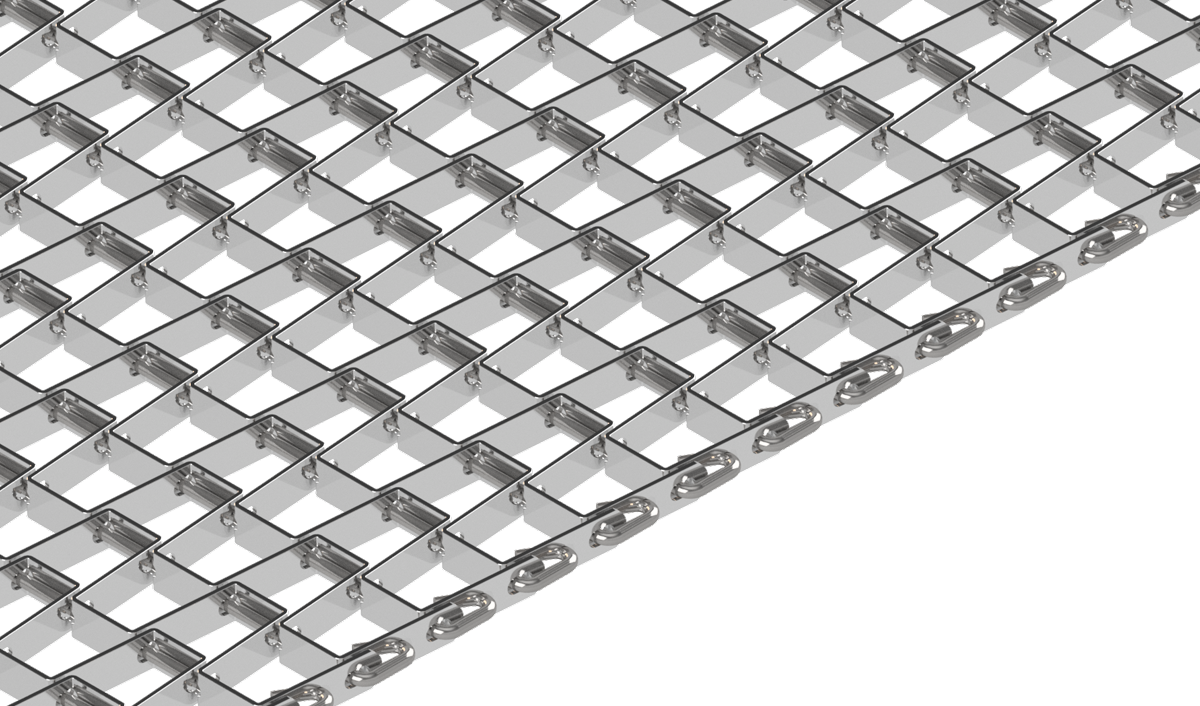

Conveyor belts for continuous ovens for enamelling and teflon coating

The products to be treated are transported on conveyor belts inside continuous ovens for enamelling and Teflon coating that reach temperatures of between approximately 500°C and 850°C.

The conveyor belts are selected and designed to guarantee the product’s stability while it moves through the oven.

Distinctive characteristics of the Costacurta conveyor belts for continuous ovens for enamelling and Teflon coating are:

- Perfect straightness

- Perfect balance between spirals or flat bar bends and connecting rods

- Wide range of mesh available

- Smooth, uniform surfaces to handle the product correctly

- Resistance also to high temperatures thanks to the quality of the materials used