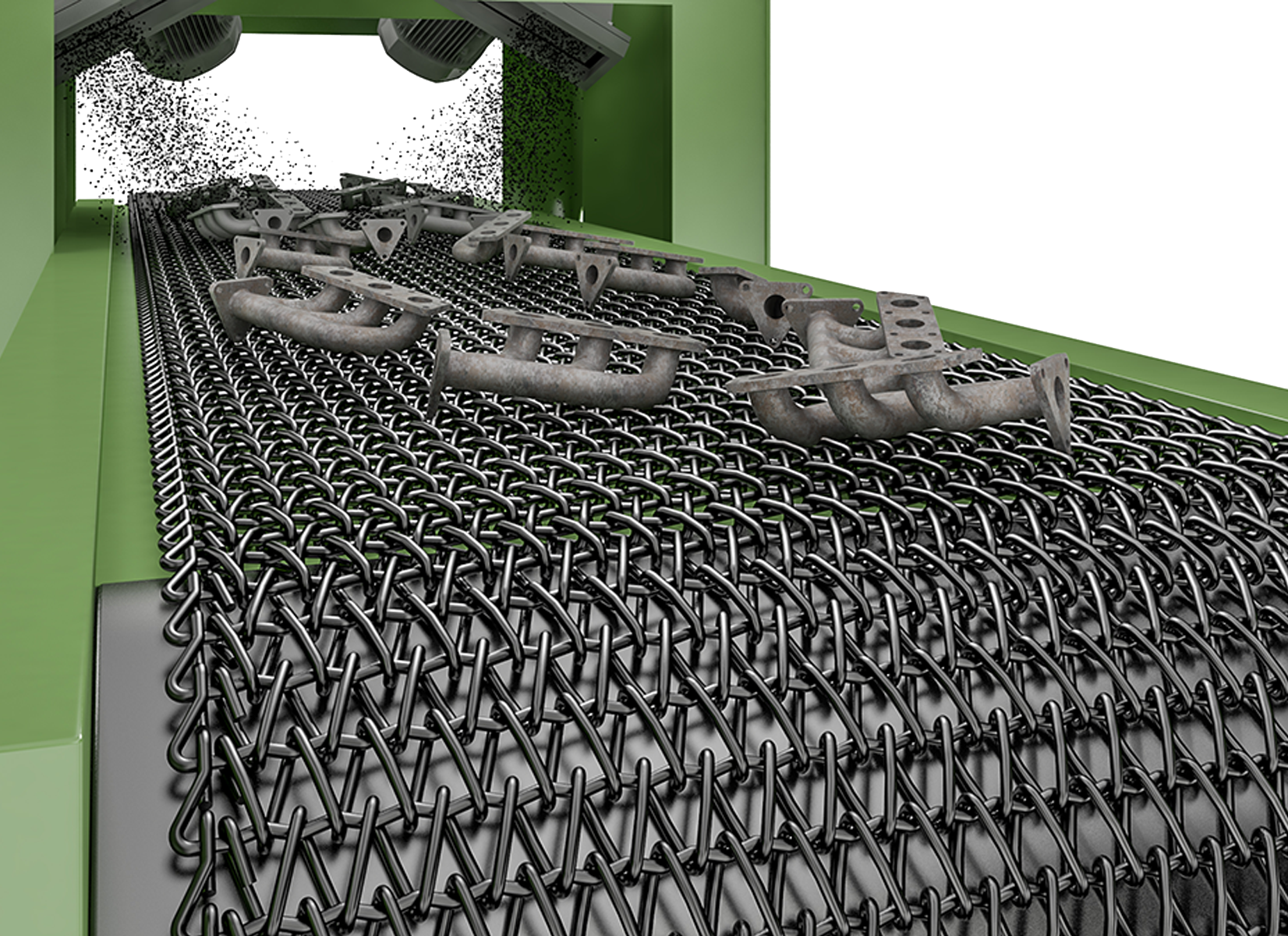

Costacurta supplies straight conveyor belts for continuous shot-blasting tunnels able to withstand mechanical stress and wear caused by jets of abrasive material.

Shot-blasting is a mechanical process in which the surface of a metal piece is eroded by a jet of abrasive material (glass beads, metal beads, aluminium oxide, silica sand) and air. When the abrasive material used is silica sand, the process is called sandblasting.

Shot-blasting is mainly used to clean the surface of the metal and cast iron parts, but it can also be used to treat wood, ceramics, stones and marbles. Shot-blasting is carried out to remove imperfections caused by production, oxides, paints, calcifications, and galvanic or plastic coatings. At the end of the process, the product is clean with a degree of roughness depending on the grit used and jet pressure.

Do you have a specific request?

Contact us now

Conveyor belts for continuous shot-blasting tunnels

Shot-blasting and sandblasting treatments take place inside continuous tunnels. The products are transported into these tunnels by conveyor belts.

These conveyor belts are selected and manufactured to guarantee the transport of the product in the tunnel where the treatment takes place.

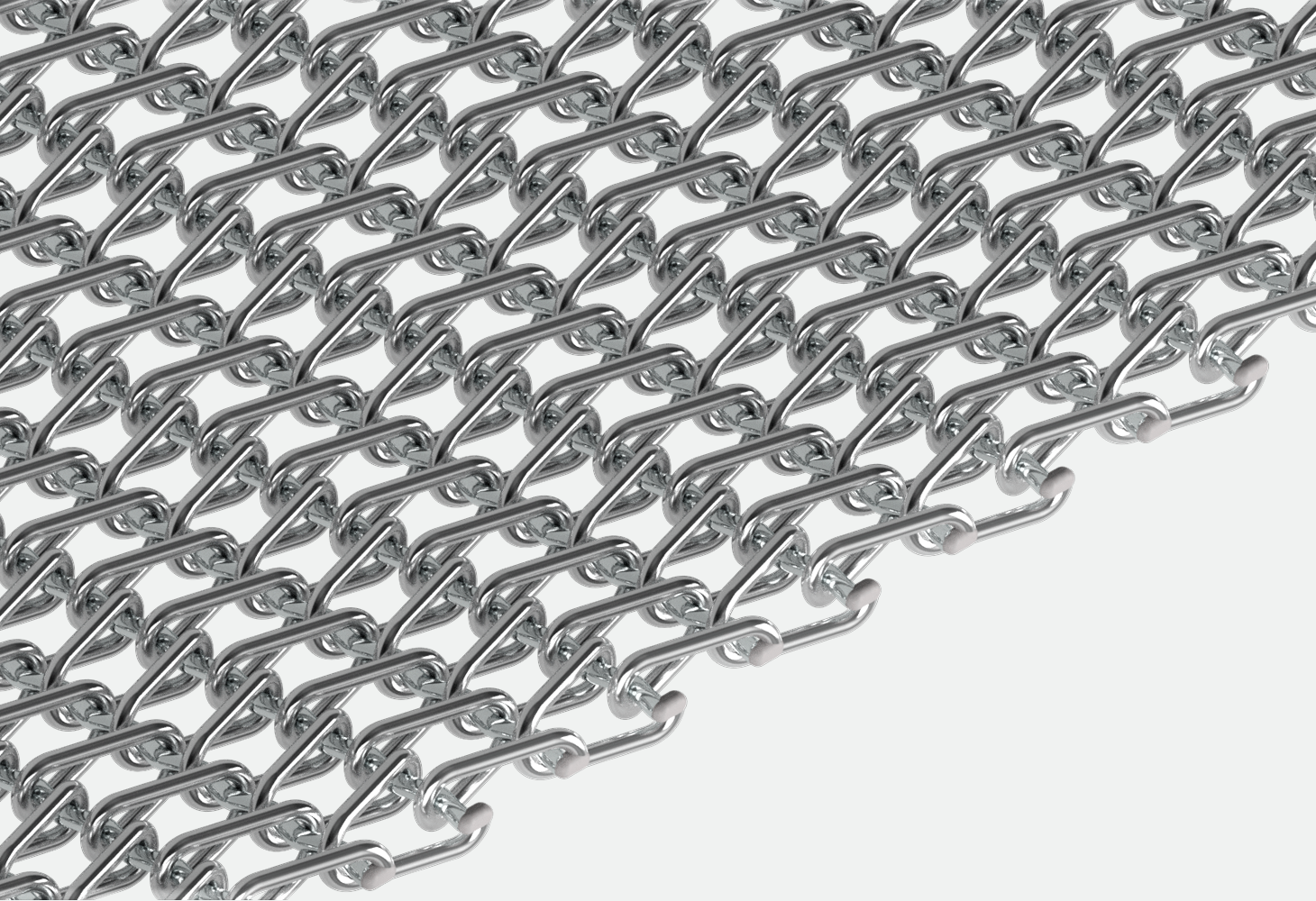

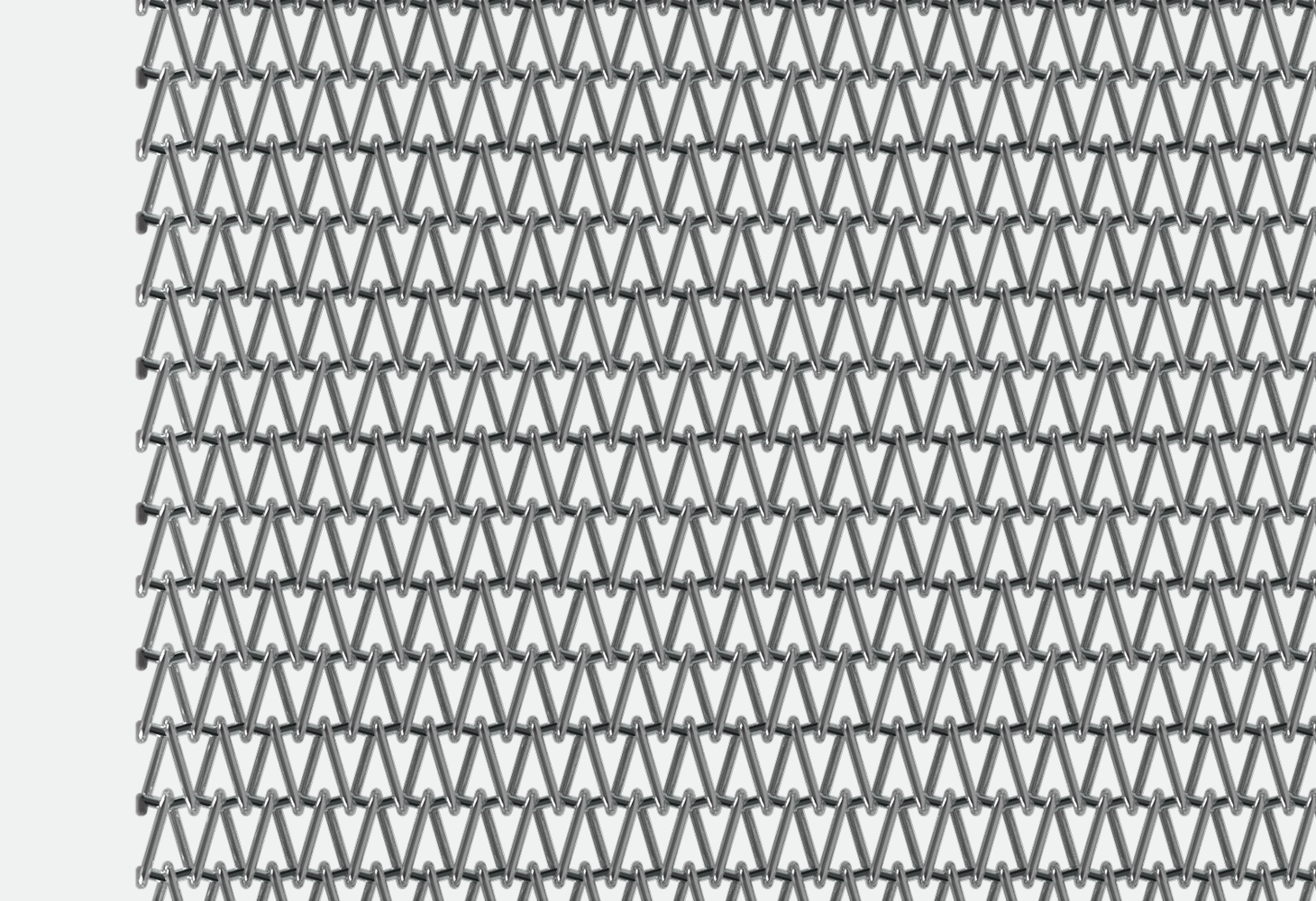

The distinctive characteristics of costacurta conveyor belts for continuous shot-blasting tunnels are:

- Perfect straightness

- Wide range of mesh available

- Smooth, uniform surfaces to support the product correctly

- High quality of the steels used

- High resistance to the mechanical stresses and to wear caused by the jet of abrasive material and air