Costacurta manufactures straight conveyor belts in refractory materials for continuous sintering ovens.

During the sintering process, powdered metallic materials are compressed and compacted. The powders are compacted in dies and then heated to a temperature which is lower than that of the material’s melting temperature. The sintering process is used in the production of objects in stainless steel, carbon steel, bronze and other alloys.

This technique is commonly used for the production of components that do not require subsequent mechanical processing in diverse industries, including the automotive one.

Do you have a specific request?

Contact us now

Conveyor belts for continuous sintering ovens

This process typically takes place inside continuous sintering ovens that can reach temperatures of approximately 1150°C. The pieces to be treated move inside the continuous ovens on conveyor belts made in special materials to withstand high temperatures.

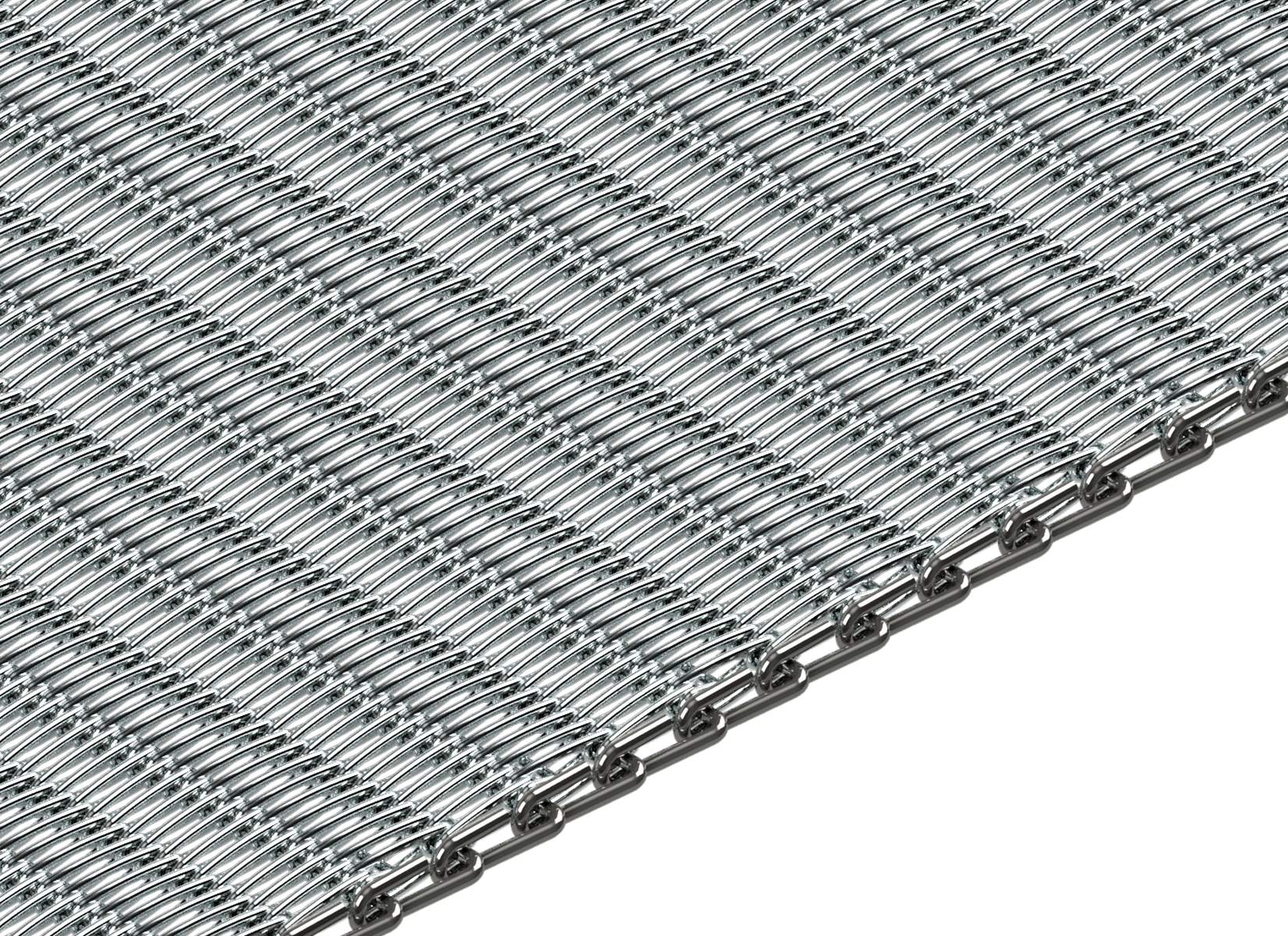

Costacurtas’ conveyor belts for high temperatures are dimensioned based on the operating conditions, the size of the parts to be treated and the workload and are normally made of stainless steel 314 (W. Nr. 1.4841), NiCr 37/18 (W. Nr. 1.4864), NiCr 80/20 (W. Nr. 2.4869).

Distinctive characteristics of the Costacurta conveyor belts for continuous sintering ovens:

- Precision of the mesh geometry and quality of the alloys used

- Wide range of mesh available