Costacurta manufactures straight conveyor belts in refractory materials for metal hardening continuous ovens and conveyor belts complete with a structure to recover parts from cooling tanks.

Hardening is a heat treatment that involves heating a material to a high temperature and then subsequently cooling it rapidly using water, oil and air. This treatment aims to obtain superior mechanical characteristics, giving the material increased hardness.

The hardening process is used on different types of steels and is commonly used to treat small metal parts, including screws, bolts, springs and bearings.

Do you have a specific request?

Contact us now

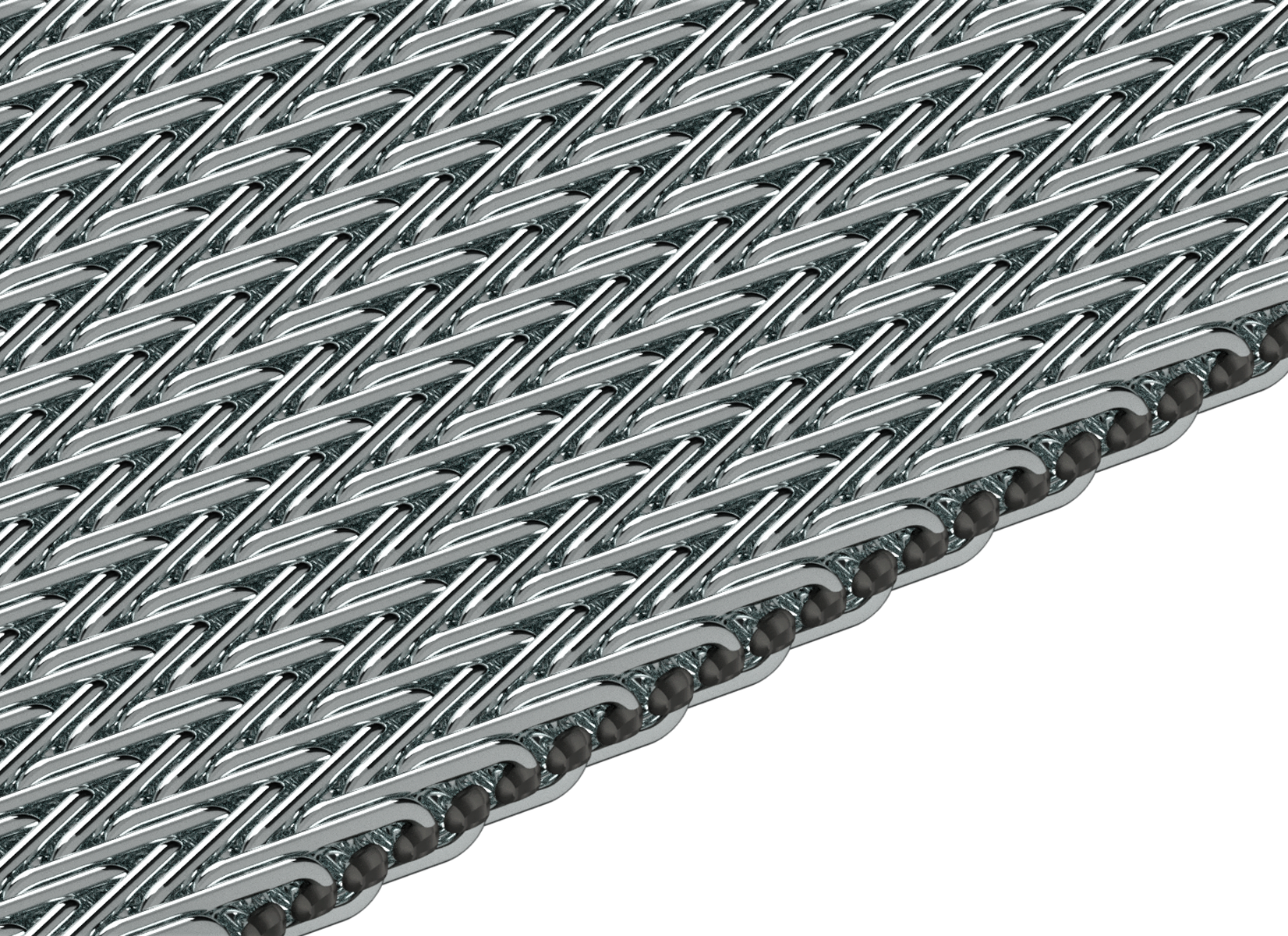

Conveyor belts for metal hardening continuous ovens

This heat treatment typically takes place inside continuous ovens for hardening that can reach temperatures of approximately 950°C. The parts to be treated are moved inside the oven on conveyor belts designed for high temperatures.

Costacurta conveyor belts for high temperatures are sized according to the operating conditions, the geometry and dimension of the parts to be treated and their load and are normally made of stainless steel 314 (W. Nr. 1.4841), NiCr 37/18 (W. Nr. 1.4864).

Costacurta also supplies belts complete with a conveying structure, called VICO-Car, for the recovery of parts from the cooling tanks in heat treatment lines. These belts are normally made of carbon steel or stainless steel 304 (W. Nr. 1.4301), complete with flights and guards according to the customer’s specifications.

As well as guaranteeing a high-quality product, Costacurta provides technicians and engineers to assist clients in the selection of the most suitable type of belt for their machinery and processes.

Distinctive characteristics of the Costacurta conveyor belts for continuous ovens for hardening are:

- Precision of the mesh geometry and quality of the alloys used

- Wide range of mesh available