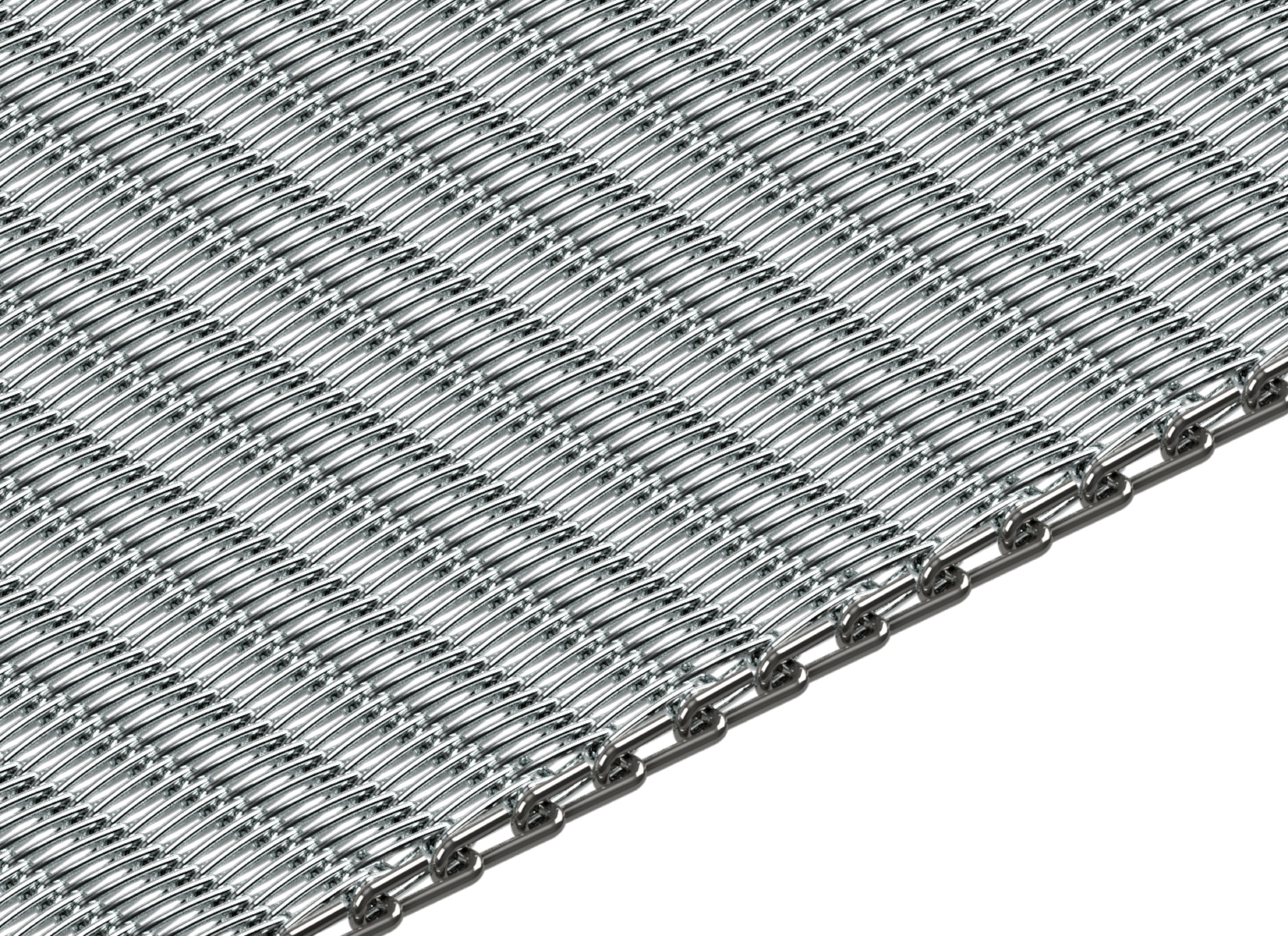

Costacurta manufactures straight conveyor belts in refractory materials for carbonitriding continuous ovens.

Carbonitriding is a surface heat treatment that involves coating metal parts with gas or liquid mixtures. This treatment increases the surface hardness of the piece through the diffusion of carbon and nitrogen.

Carbonitriding is used to treat metal parts that require greater surface hardness, typically low-carbon steels and small metal parts subject to wear (e.g. Screws, bolts and gears).

Do you have a specific request?

Contact us now

Conveyor belts for continuous ovens for carbonitriding

Carbonitriding typically takes place inside continuous carbonitriding ovens that can reach temperatures of approximately 930°C. The parts to be treated are moved inside the continuous oven on conveyor belts for high temperatures.

Costacurta’s conveyor belts for high temperatures are dimensioned based on the operating conditions, the size of the parts to be treated and the workload, and are normally made of stainless steel 314 (W. Nr. 1.4841), NiCr 37/ 18Cb (W. Nr. 1.4887).

Distinctive characteristics of the Costacurta conveyor belts for continuous carbonitriding ovens:

- Precision of the mesh geometry and quality of the alloys used

- Wide range of mesh available