Costacurta manufactures straight conveyor belts in refractory materials for annealing and normalising continuous ovens.

The annealing heat treatment process is mainly used on alloy steels and copper. The metal alloy is heated to a temperature that is usually lower than its melting temperature and is then cooled slowly. Annealing aims to achieve a chemical, structural or mechanical balance of the material. Annealing reduces the material’s hardness and increases its ductility.

Normalising is a heat treatment that involves heating the material to a high temperature, maintaining this temperature for approximately 15 minutes and then cooling the material in calm air. This process aims to refine and homogenise the crystalline grain and eliminate the tensions caused by plastic deformation processes. This is necessary to be able to subject steels to subsequent heat treatments. The normalising process is used to treat parts for the mechanical industry, including rolled steels, castings, forgings, carbon and low-alloy steel castings.

Do you have a specific request?

Contact us now

Conveyor belts for continuous annealing and normalising ovens

These treatments typically take place inside continuous annealing and normalizing ovens that can reach temperatures of approximately 900°C. The material to be treated moves inside the continuous ovens on conveyor belts made in special materials to withstand high temperatures.

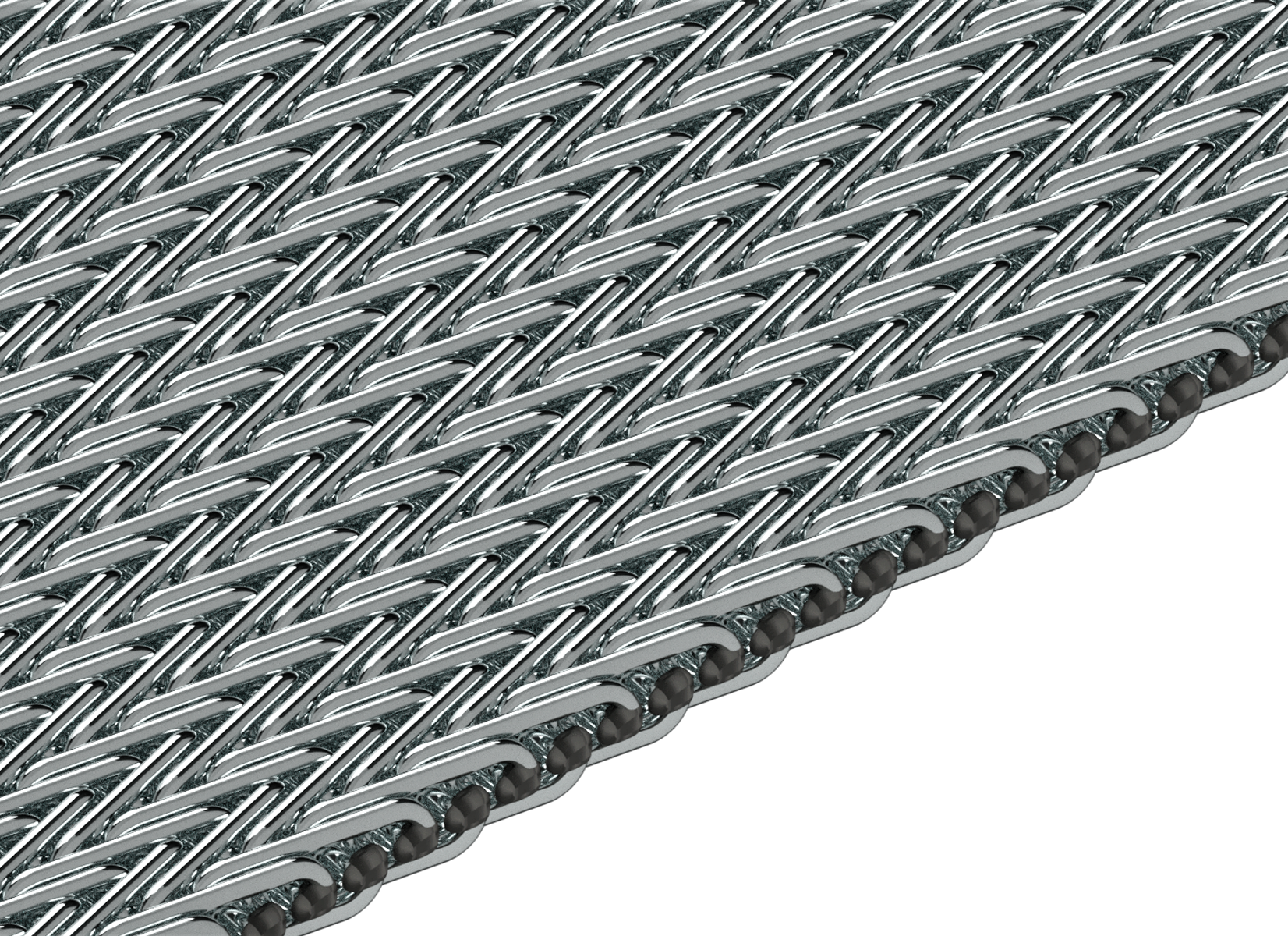

Costacurta’s conveyor belts for high temperatures are dimensioned based on the operating conditions, the size of the parts to be treated and the workload and are normally made in stainless steel 314 (W. Nr. 1.4841), NiCr 37/18 (W. Nr. 1.4864).

Distinctive characteristics of the Costacurta conveyor belts for continuous annealing and normalizing ovens:

- Precision of the mesh geometry and quality of the alloys used

- Wide range of mesh available