Costacurta manufactures drilled and perforated plates for use in screw presses used for the pressing of exhausted beets used in sugar production.

In sugar production, sucrose is extracted from the sugar beets. On arrival at the production plant, the sugar beet roots are washed and cut into thin strips. These are then transferred into a diffuser where they are soaked in hot water to extract the sugar content. The diffuser separates the pulp from the liquid. The output liquid from the diffuser is called raw juice and is used to recover the sugar through evaporation.

The exhausted beets (pulp) are still very wet, with small quantities of sugar remaining in the water inside them.

Do you have a specific request?

Contact us now

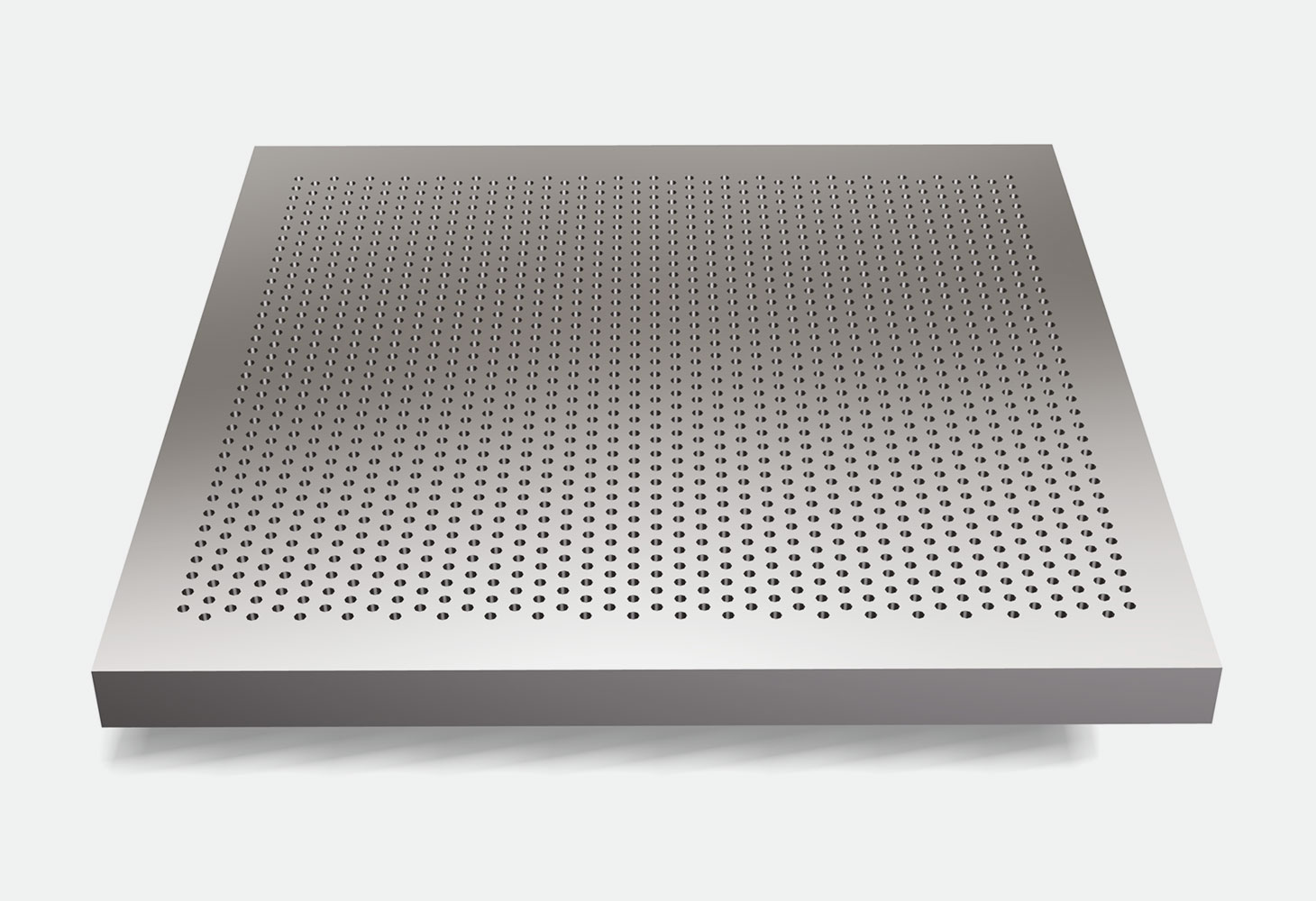

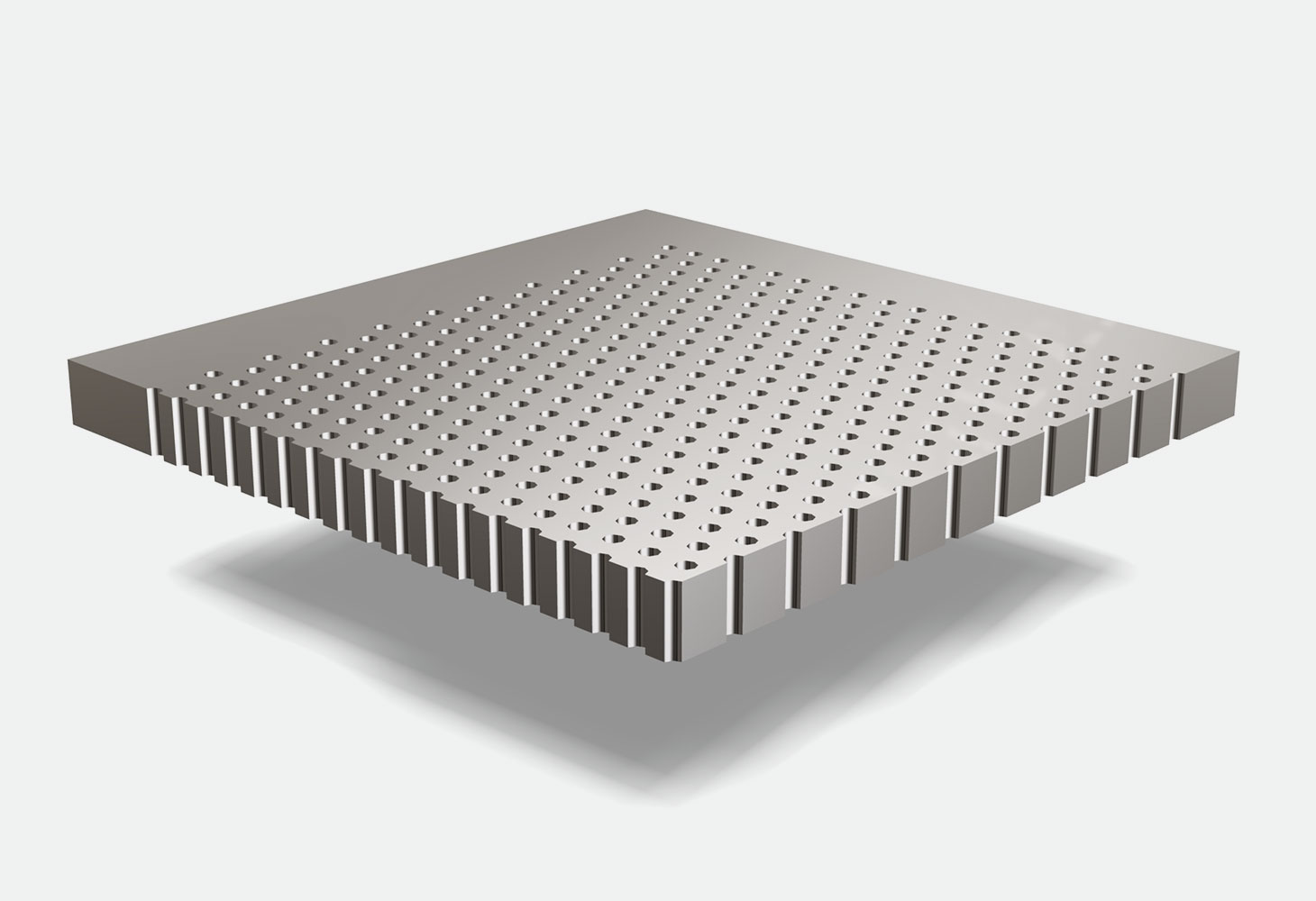

PERFORATED PLATES FOR SCREW PRESSES FOR THE PRESSING OF EXHAUSTED BEETS

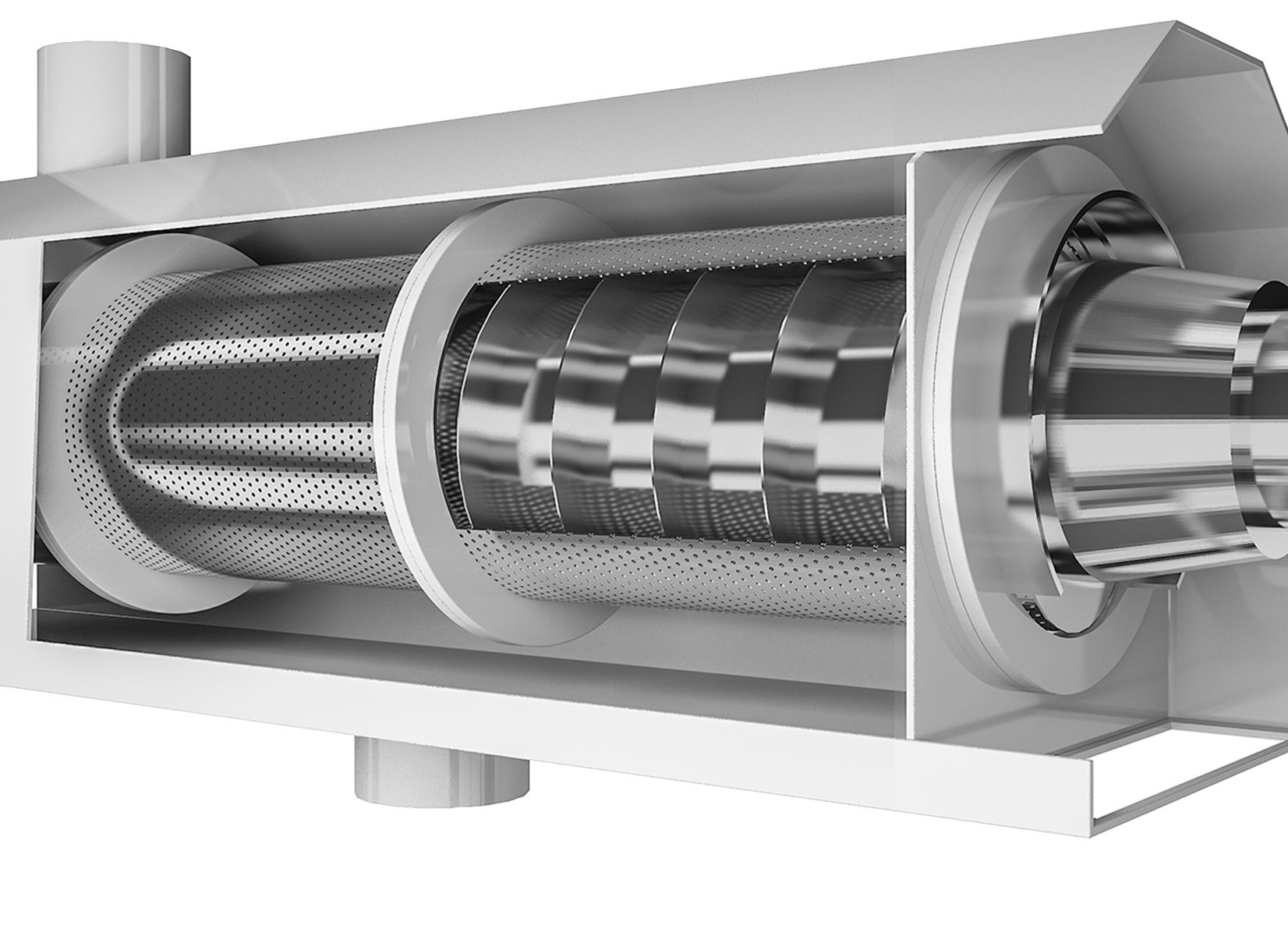

To retrieve sugar residue from the used beet, the pulp is placed in a screw press. The screw press is a slow-moving machine in which a conical screw rotates inside a perforated cylindrical filter. During the pressing phase, the pulp is pressed with increasing force against the metal filter in order to obtain as much juice as possible. The holes in the filter allow the water to drain out. The remaining water is collected and used as diffusion water while the remaining beet pulp is used as livestock feed.

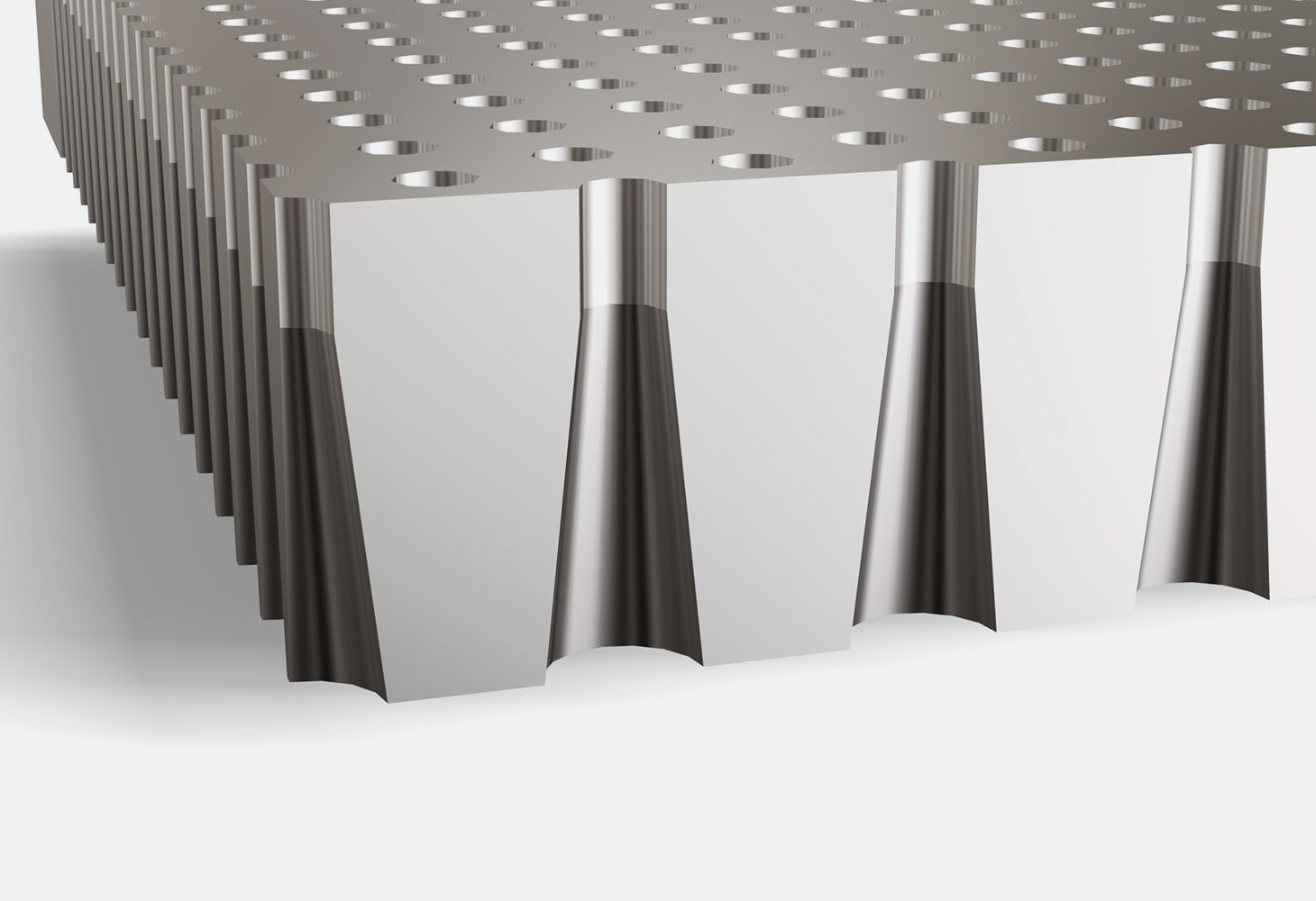

In sugar production, Costacurta’s drilled plate (that forms the filter of the screw press) is a fundamental element of the machine. The perforated plate must be sufficiently thick to resist pressure, and have different kinds of perforations (cylindrical, conical and step drilled) to allow filtration of the water and its separation from the solid pulp.

Distinctive characteristics of Costacurta’s drilled plates for screw presses are:

- High quality and precision of the drilling

- High quality of the material used