Costacurta manufactures perforated plates and wedge wire screen panels for lauter tuns and filter candles made of vico-screen (wedge wire screens) for pressure filters.

Typically, Costacurta’s filtering elements (perforated plates, wedge wire screens and filter candles) are used in different stages of the beer production process, from melting to filtering.

The filtering element is selected based on the plant layout and the operating conditions.

All of the filtering elements (perforated plates, wedge wire screens or filter candles) are easy to clean and made of high-quality materials to guarantee utmost hygiene.

As well as offering a high-quality product, Costacurta provides technicians and engineers to assist clients in the selection of the filtering elements and their installation.

Beer production consists of the pressing of barley or wheat, boiling and mashing, fermentation and maturation that transforms the yeast and sugars into alcohol and final filtration and clarification.

Do you have a specific request?

Contact us now

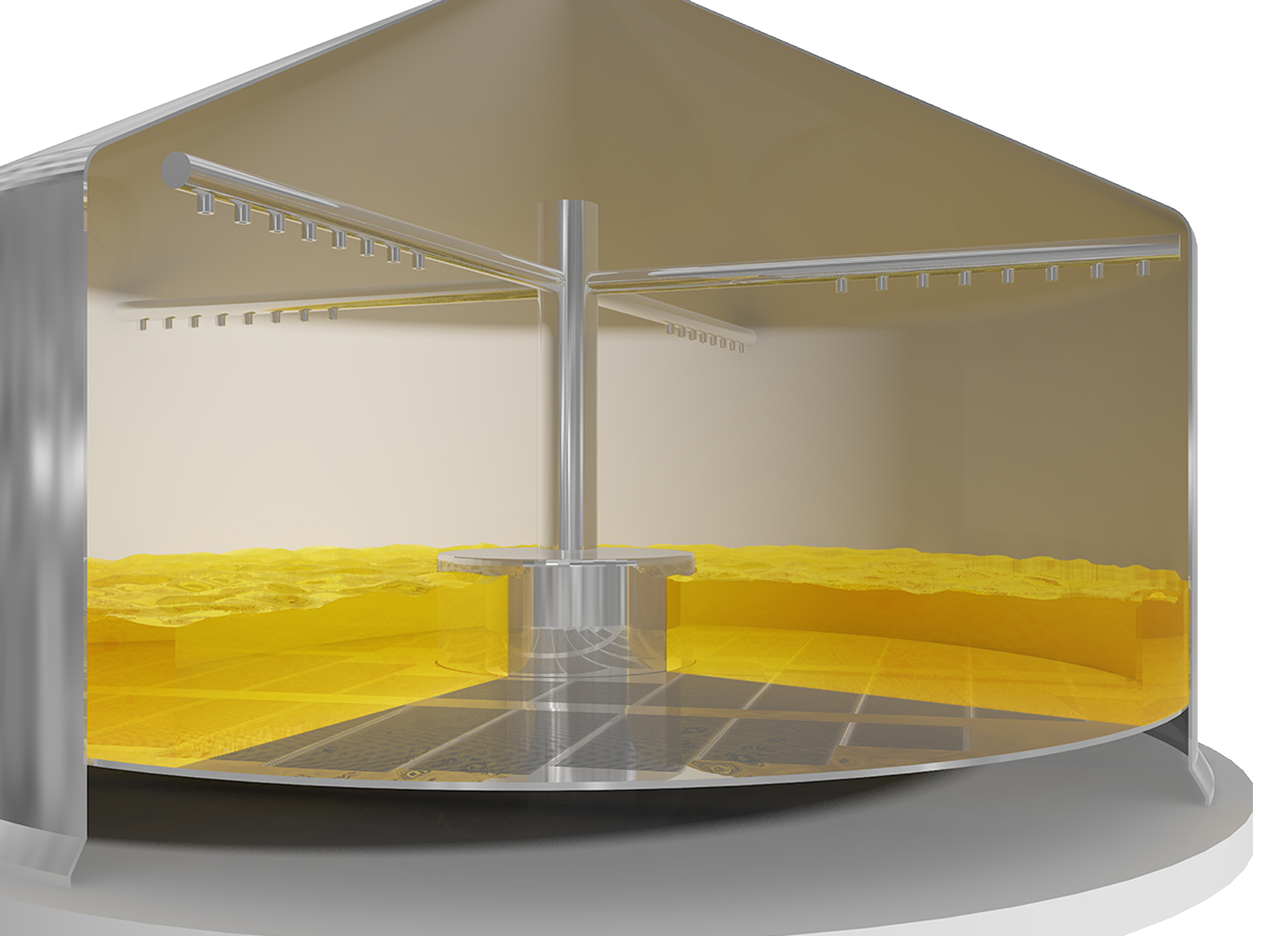

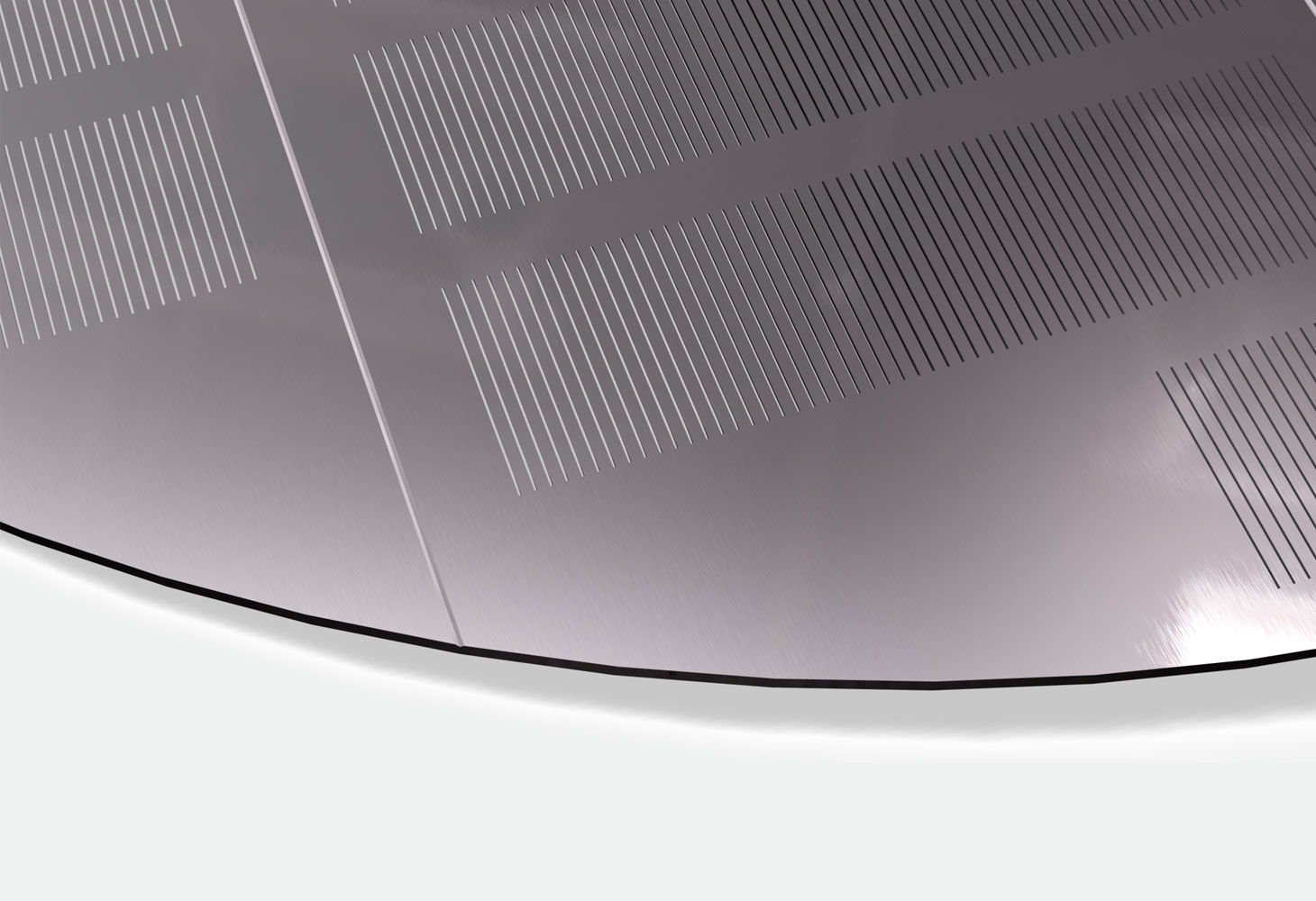

PERFORATED PLATES AND WEDGE WIRE SCREENS FOR LAUTER TUNS

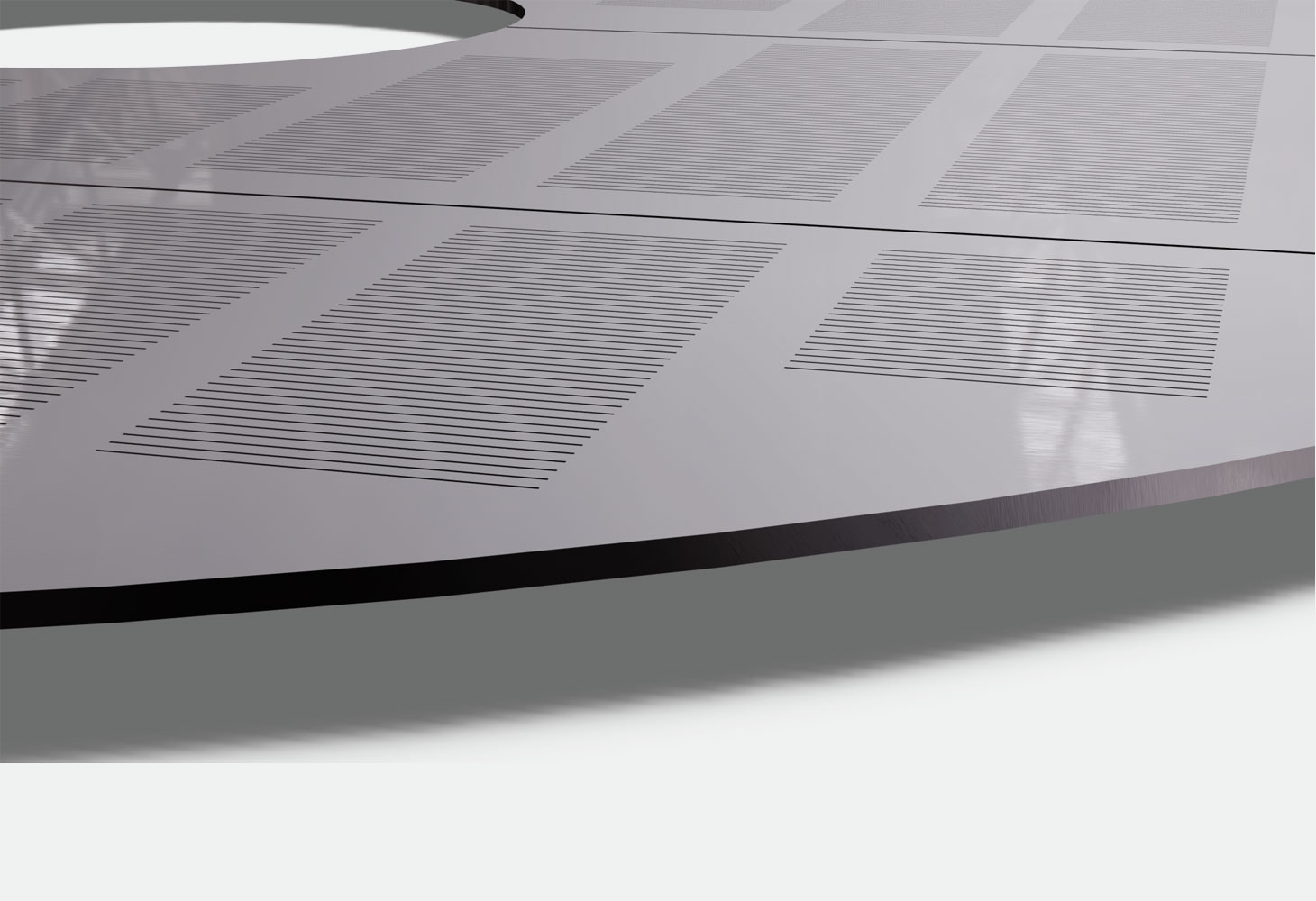

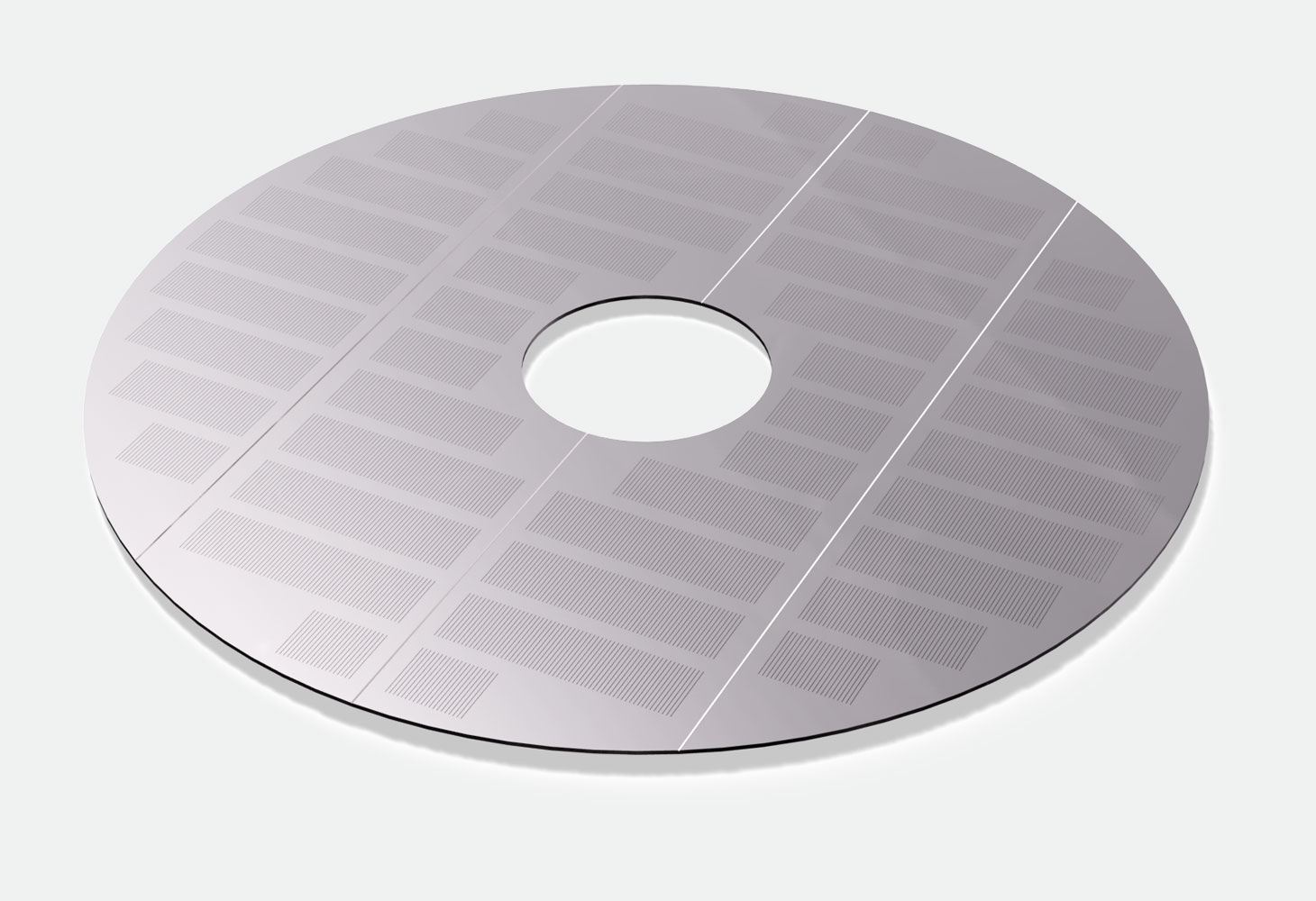

In the pressing process, malted barley grains are ground and mixed with hot water to activate the enzymes in the malt. Once the starches have been converted into sugar, the solution obtained is transferred into a large vessel with a false bottom (lauter tun), consisting of a stainless steel perforated plate (it could be slotted or milled) or of a stainless steel wedge wire screen that acts as a filter.

The solution is drained through the openings of the filtering element, while the solid residues are retained in the vessel. These residues are subsequently compressed to extract any remaining liquid and then sold as livestock feed. The solution drained through the filter moves on to the subsequent processing phases.

Distinctive characteristics of Costacurta’s perforated plates and wedge wire screen panels for lauter tuns are:

- Regularity and precision of the holes to guarantee correct filtering

- Smooth, perfectly flat surface to ensure homogeneous distribution of the product

Wedge wire screen filter candles for pressure filters

In the final filtration or clarification stage, the unfiltered beer passes through a cylindrical container with candle filters made of wedge wire screens. In turn, the candle filters are coated with filtering materials to filter the beer, retaining the solid particles and permitting only the liquid to flow through the candle filters which is then conveyed to a collection plate or manifold.

The size of the candle filter openings allows the passage of the liquid but not of the filtering material and solids, guaranteeing very fine filtration.

Distinctive characteristics of the Costacurta VICO-Screen candle filters for precoat filters are:

- Regularity and precision of the openings (to tens of microns) to guarantee correct filtering

- High quality of the material and welding to offer excellent resistance also at extremely high pressures.