Costacurta supplies wire cloth and mesh filtering discs used for the production of rubber sheaths for cables in the electrical sector.

These sheaths are used to cover the cable, protecting it and preventing accidents, thus ensuring total insulation of the cable’s vital areas from the outside environment. They are usually manufactured through extrusion of the molten material which is then left to cool.

Costacurta supplies filtering discs for extruders used in the processing of isolating thermoplastics and thermosetters for the production of rubber sheaths for electrical cables.

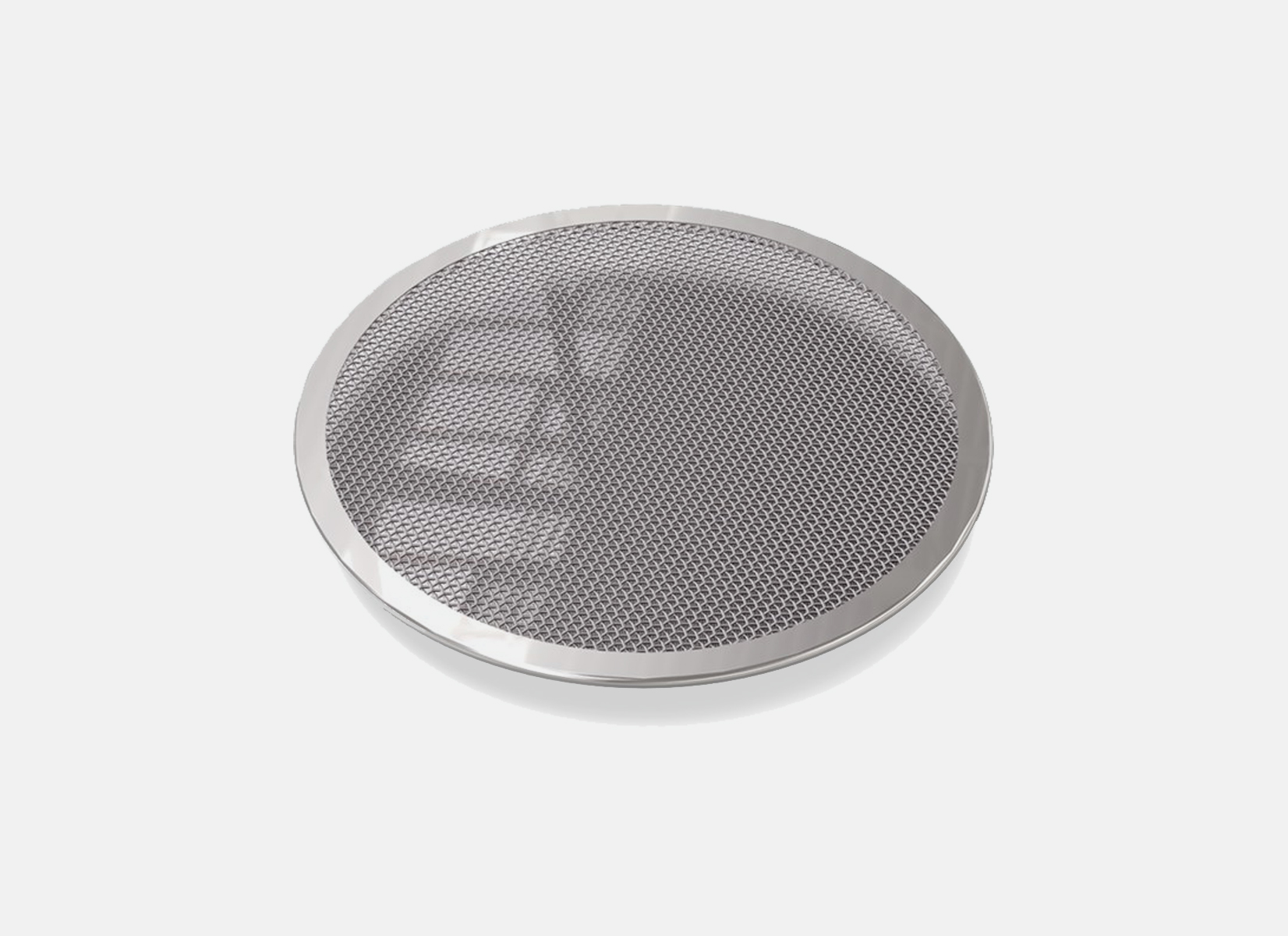

Filtering discs for extruders

Extrusion is the most commonly used process for processing thermoplastic and thermosetting insulation. The materials are first melted inside the extruder using the mechanical heat generated by the friction of the screws and the electrical resistors mounted on the outside of the cylinder. Once the material has melted, it is forced to pass through a spinneret which determines its final shape and size. A filtering disc is mounted on the head of the spinneret.

Distinctive characteristics of the costacurta filtering discs for this type of machine are:

- Wide range of solutions: the filtering discs can be made from single cloths or combinations of cloths with different characteristics, punched in numerous combinations of shapes and sizes.

- High quality of the material used and of the production process