The Oil&Gas industry is undergoing a transformation and now faces a dual challenge:

- seeking new solutions for producing clean and sustainable energy

- satisfying the world’s immediate energy needs, optimising the existing processes and reducing emissions.

Costacurta can support companies in facing these challenges.

Leveraging calculation models that we have developed and validated over more than 70 years in the field, our company can support Oil Companies and EPCs with a free consultancy service on how to optimise their gas-liquid and liquid-liquid separation processes, aiming to reduce both their CAPEX and their OPEX.

OUR EXPERTISE: OPTIMISATION OF SEPARATION PLANTS

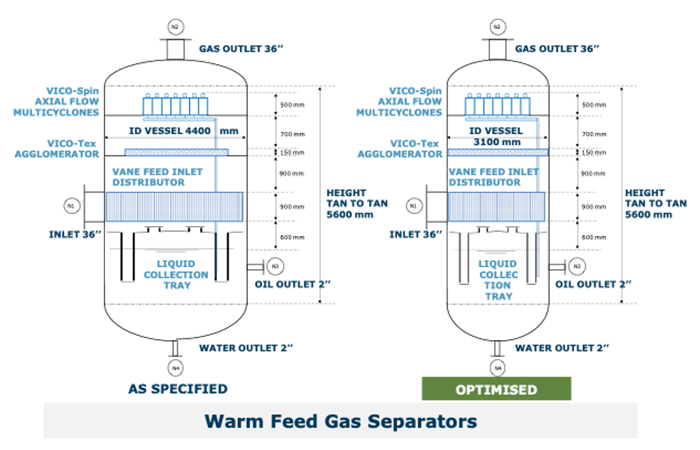

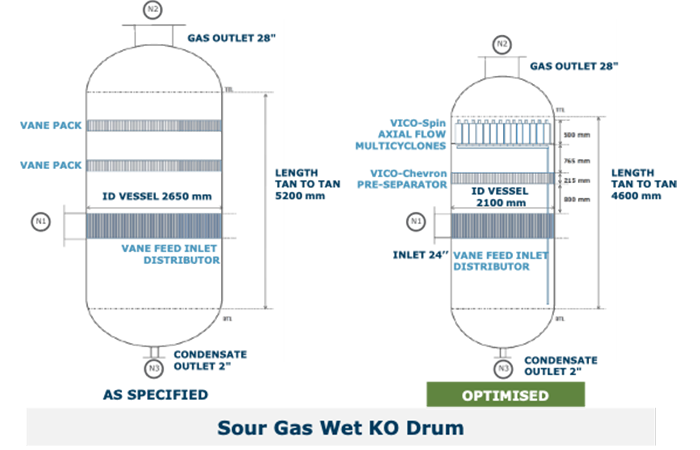

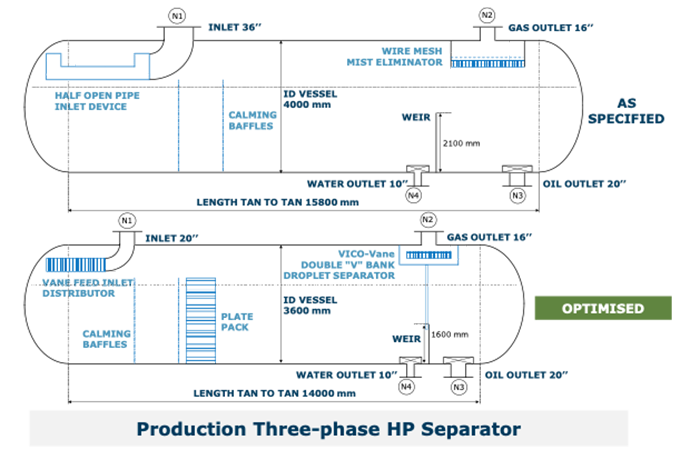

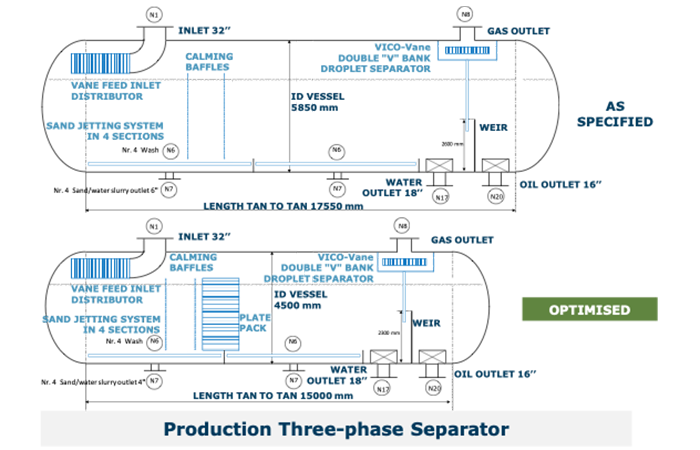

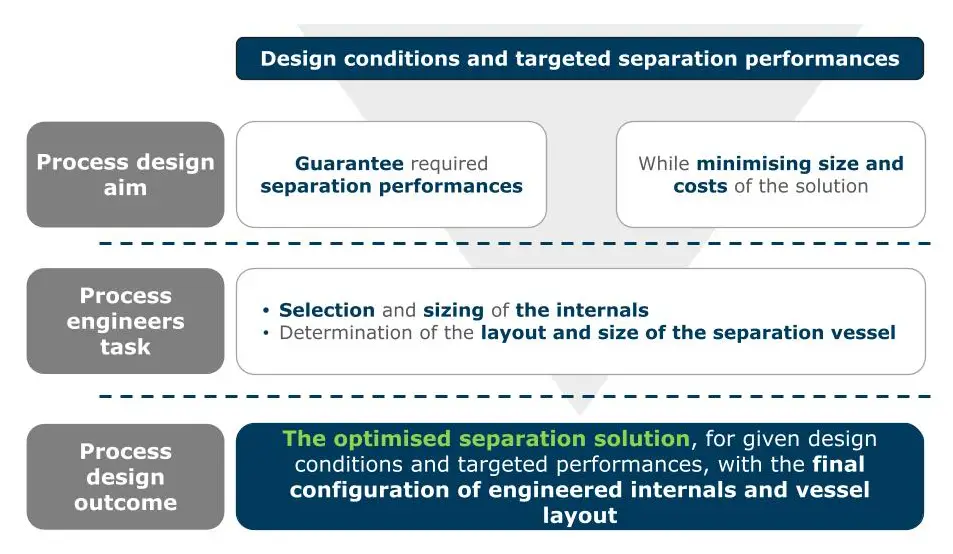

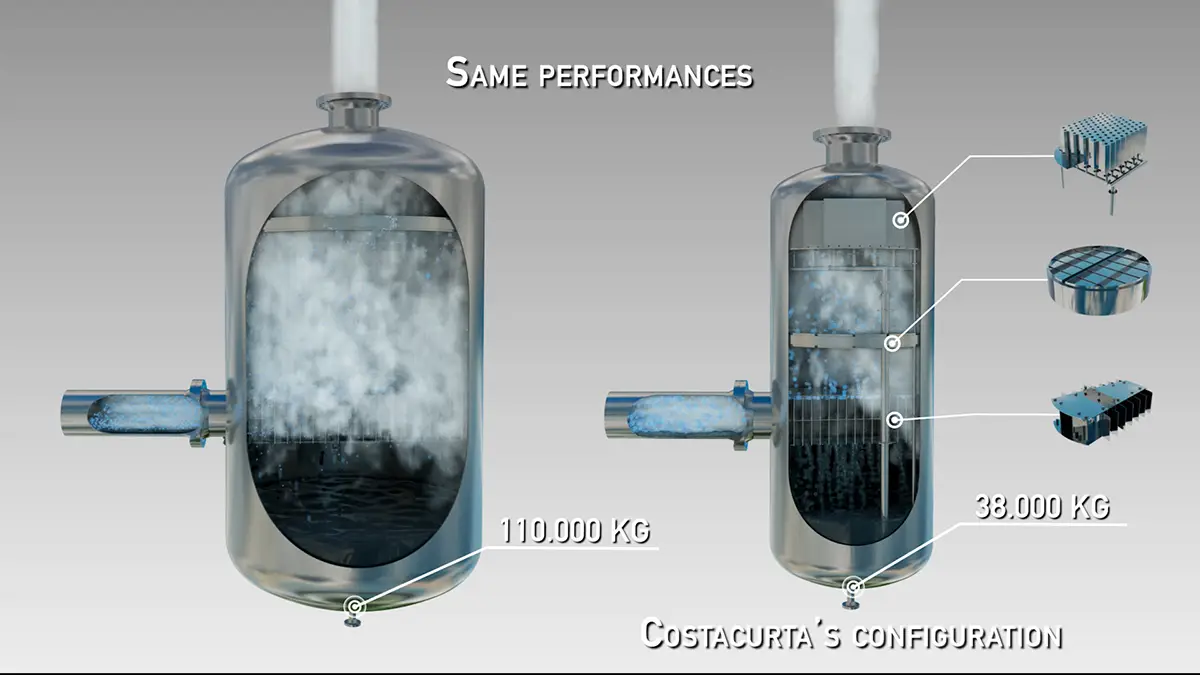

Starting from the gas-liquid and liquid-liquid separation targets and from the operating conditions of the plant, our process engineers are able to select and design separator internals, minimising the weights and dimensions and thus the costs of the solution.

The output of process design is an optimised solution that includes final configuration of the vessel and the selected internals, in order to guarantee the required separation performance.

GREENFIELD

Right from the FEED phase, our process engineers are able to select and size the best separator internals to satisfy particular separation requirements and determine the layout and size of the separator, offering a complete and optimised solution for new plants and, where possible, reducing their size, weight and costs.

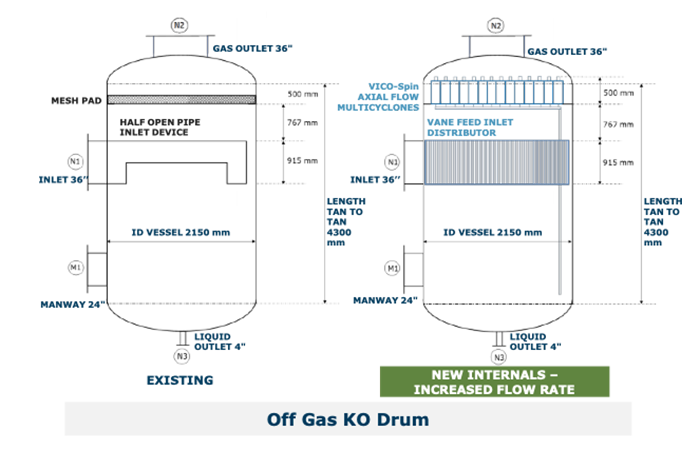

REVAMPING

Our team is able to support customers in the revamping of separators when they no longer guarantee an appropriate separation performance, due to malfunctions or to changes in the operating process, such as a significant increase in the flow rate or a change in the characteristics of the fluids. Our engineers can solve separation issues, providing assistance in examining the problem and proposing potential solutions.

In both cases, the assessment phase and definition of the technical proposal that includes the internals and layout of the vessel are provided to Oil companies and EPCs free of charge and under no obligation.

OUR APPROACH: HOW WE PROVIDE THIS SERVICE

- Information gathering (operating conditions, separation targets, dimensions, specific issues)

- Preparation of an optimised technical proposal, comprising both the internals and the separator, applying our process calculation steps

- Discussion with the customer and gathering of feedback / technical clarifications

- Finalisation and sharing of the design proposal, complete with process computations and the technical datasheets of the proposed internals

OTHER TOOLS WE CAN USE

In addition to the process design service, Costacurta can also offer other services, which are proposed and priced on the basis of the particular design specifications.

CFD

Computational Fluid Dynamics is the numerical solution of the Navier Stokes equations for single-phase and multiphase flows. It simulates the behaviour of gas and liquid phase fluids in equipment. It is therefore useful in optimising the design of separators and in performing studies for the development of new equipment, significantly reducing the number of tests required.

FEA

Finite Element Analysis is the numerical solution of a system of partial differential equations that allows calculation of stresses and deformations on bodies subject to external and internal loads. Combined with CFD, it allows optimisation of mechanical, fluid-dynamic and process design.

2D and 3D design

2D and 3D modelling contributes to optimising the geometries of separators and their relative internals. It is also useful for checking the feasibility of modifications to existing equipment, with the aim of reducing or avoiding the welding of parts under pressure.

These tools allow our process engineers to verify the behaviour of the internals and to validate the optimised solution proposed, or possibly to refine the calculation and the separator design.

SOME EXAMPLES OF OPTIMISED CASES

In over 70 years of operation in the gas-liquid and liquid-liquid separation sector, Costacurta has had the opportunity to address and solve separation issues in various applications associated with the production of oil and gas, refining and chemical and petrochemical processes.

Does your project require separators?

Or are you facing separation issues at the plant?

Contact us: we can study an optimised solution for you, with no cost or obligation.

DISCOVER MORE