At Costacurta, we are specialised in the production and supply of reactor internals. Technology Providers can leverage on our long-standing experience in designing and manufacturing reactor internals when designing internals to enhance the performances of an existing process or when developing a new one. The constructional details of the reactor internals are crucial to:

- improve process performance and/or energy efficiency

- address process performance issues

- address mechanical issues

- reduce overall hardware costs.

Do you have a specific request?

Contact us nowAt Costacurta, we are committed to supporting our customers no matter how challenging the project or how critical the process is. Right from the outset, we leverage our extensive experience in the mechanical design and manufacturing of reactor internals to support customers through their entire product development process, spanning from the concept and prototyping to manufacturing engineering.

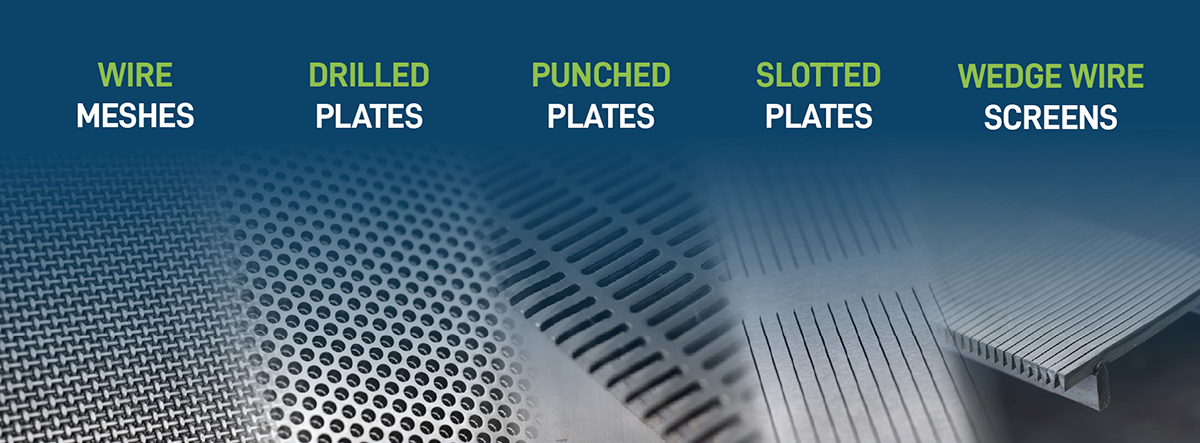

SELECTING FILTERING ELEMENTS

Filtering elements, as part of the reactor internals, play a dual role:

- Catalyst retention and support — they minimise catalyst breakages, prevent catalyst leakages and plugging, and endure the load of the catalyst and the differential pressure.

- Fluid distribution — they ensure proper fluid distribution as envisioned during the process design stage.

Costacurta can help Technology Providers identify the best solution for specific process and mechanical conditions.

Thanks to the wide range of solutions available in-house, Costacurta can support Technology Providers in selecting the right filtering elements, not biased by a need to sell one specific component, but with the aim of identifying the ideal product based on the following characteristics:

- opening sizes

- opening geometry

- open area

- mechanical strength

- surface smoothness.

UNDERTAKING MANUFACTURING FEASIBILITY STUDIES

After supporting Technology Providers in selecting the filtering elements, our engineers can carry out a manufacturing feasibility study to verify the feasibility of the proposed solution from a mechanical and manufacturing point of view. If there is space for improvement, our engineers are also capable of proposing alternative solutions to optimize production costs while maintaining the same performance.

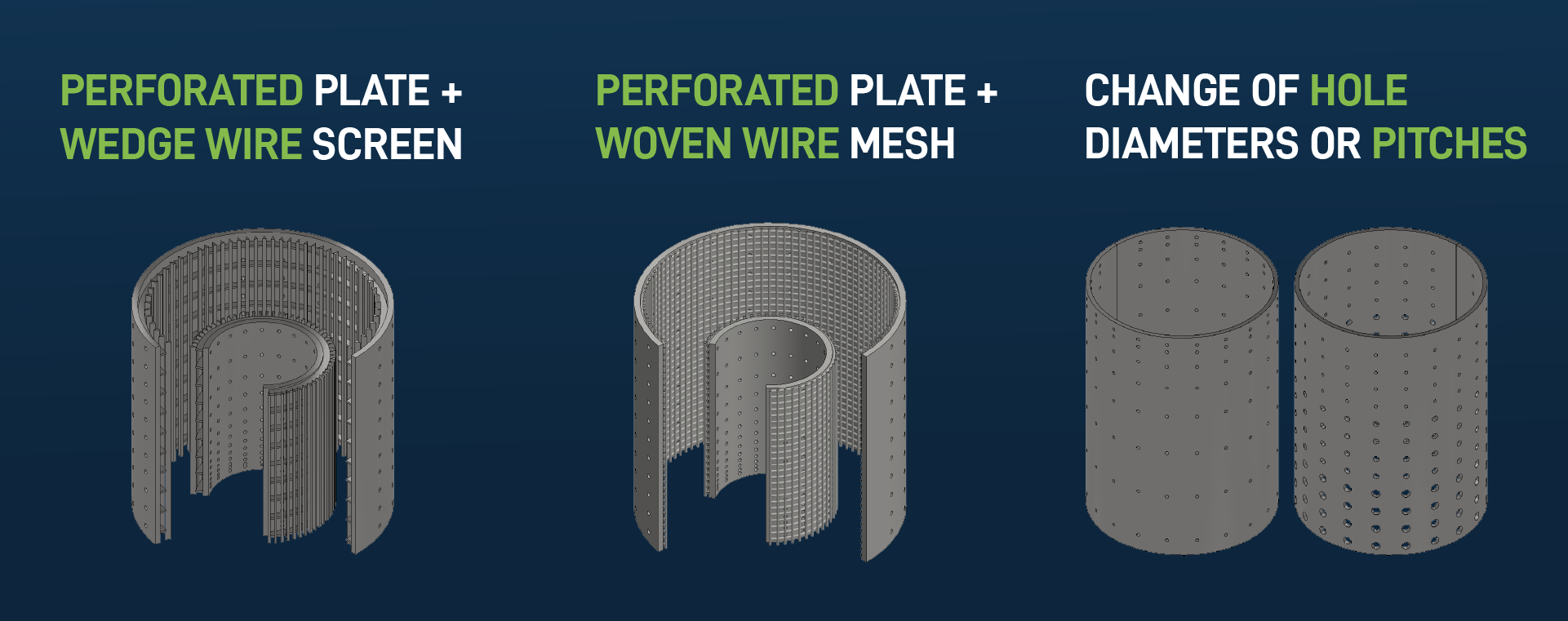

When there is a need to optimise the fluid distribution, particularly in very high radial flow reactors, Costacurta can support the Technology Provider in identifying and verifying the best combination of:

a filtering element

its selection directly impacts catalyst retention and fluid distribution

perforated plates

to provide additional mechanical strength while allowing precise control of the pressure drop.

Uniform fluid distribution throughout the reactor can be achieved by varying the open areas at different elevations by specifically selecting hole diameters and/or hole pitches of the perforated plate.

VALIDATING DESIGNS THROUGH PROTOTYPING AND TESTING

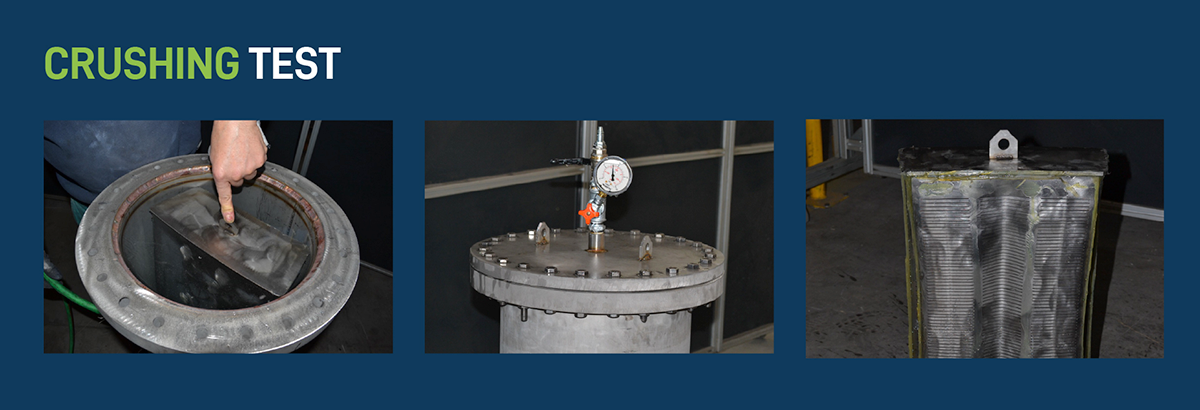

We offer comprehensive prototyping for our customers to validate the process performance and to test the mechanical resistance.

- Prototyping — our manufacturing expertise allows us to produce prototypes of proposed designs, including variations of the same with different filtering elements. Prototyping enables Technology Providers to compare different solutions and validate the process performances prior to finalising a new design.

- Crushing tests — on request, Costacurta can conduct specific crushing tests to simulate operating conditions and test the mechanical strength of the reactor internals.

Examples of a crushing test to experimentally verify at what pressure a slotted internal component would collapse.

DISCOVER THE OTHER DISTINCTIVE ELEMENTS OF REACTOR INTERNALS