Costacurta has been manufacturing reactor internals for over 70 years, in accordance with the designs and specifications of major Technology Providers worldwide.

Do you have a specific request?

Contact us nowGiven our extensive experience, we handle every stage of the production process in-house, from selecting and constructing the most suitable filtering elements to reactor internals’ manufacturing and assembly. The entire process is subject to stringent quality controls.

Watch our video, which showcases our state-of-the-art production facilities in Italy and the comprehensive quality control measures we implement to ensure the best quality for our customers.

THE IMPORTANT ROLE OF THE FILTERING ELEMENT FOR THE QUALITY OF REACTOR INTERNALS

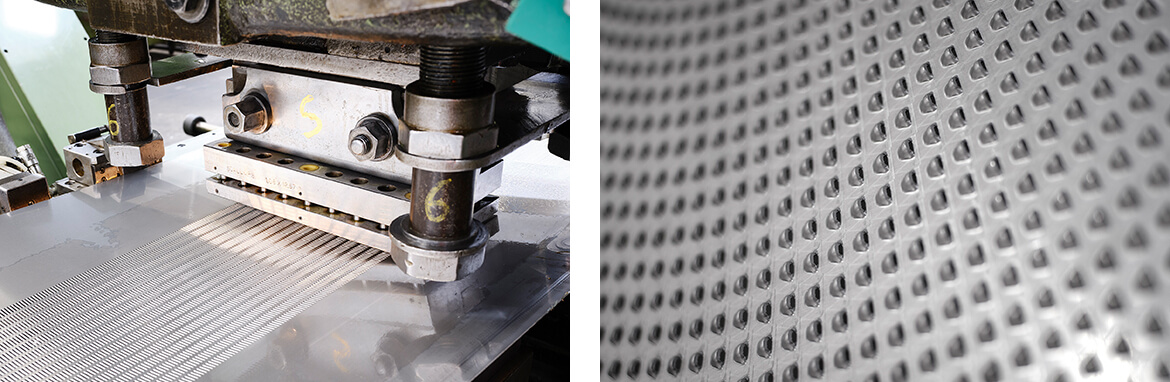

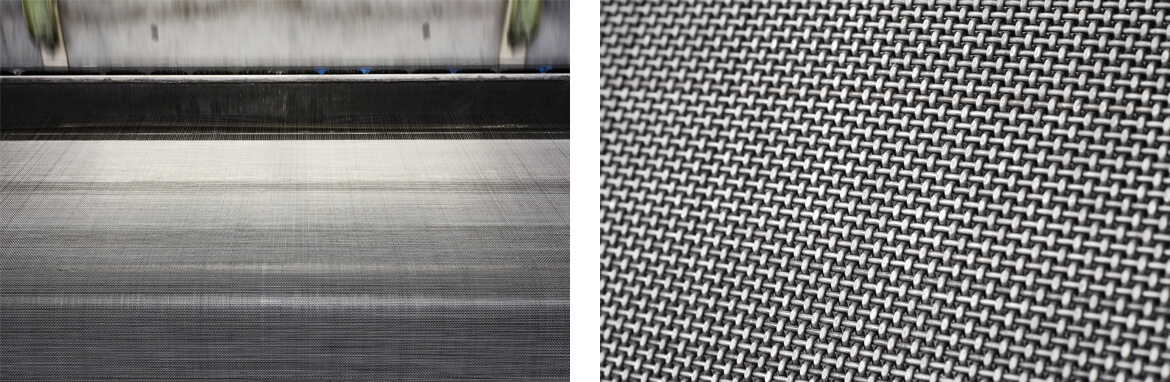

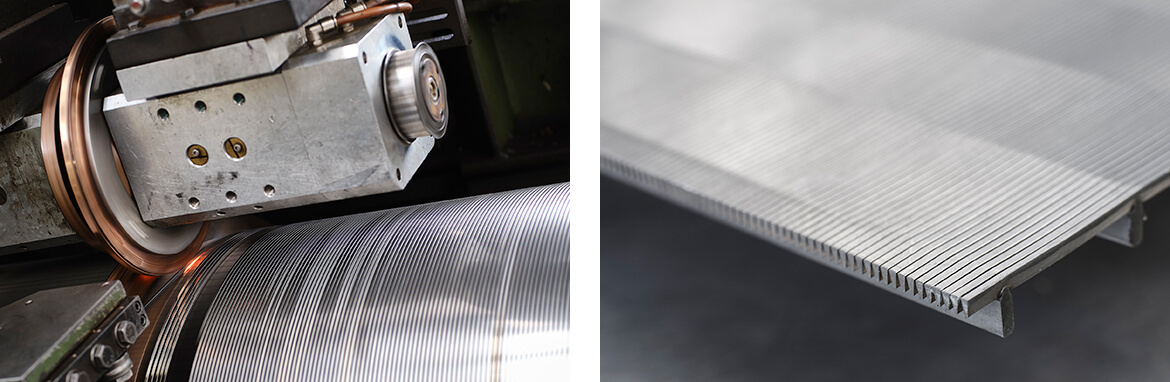

The quality of reactor internals depends on the quality of the constituent components and, above all, the quality of the filtering element, which has an essential dual function in a reactor: holding the catalyst in place and allowing the passage of fluids to guarantee the distribution envisaged during the process design stage.

The precision of the openings and compliance with tolerances are fundamental for this function. Moreover, the filtering element must have sufficient mechanical strength to withstand the stresses during operations.

One of Costacurta’s strengths is its ability to manage the entire production process in-house, from the manufacture of the filtering elements in wire or plate – metal cloths, perforated plates and wedge wire screens – through to the finished reactor internals. This strength contributes to achieving a high-quality finished product and a high level of production flexibility, which guarantees better control of compliance with scheduled delivery times and also, in many cases, the possibility of guaranteeing fast deliveries when expediting is needed.

From thin to thick plates

Costacurta manufactures Reactor Internals from plates, mainly in stainless steel, that can be between 1 mm and 200 mm thick and it pays great attention to the quality of the plates, procuring solely from highly qualified and internationally renowned manufacturers. Over the years, Costacurta has gained experience in all the processes and, above all, in welding thick and thin plates.

FROM SINGLE ELEMENTS SIZED TO PASS THROUGH A MANHOLE, TO ASSEMBLED INTERNALS UP TO 100 TONS

Costacurta produces reactor internals consisting of components that can extensively vary in size. Some are relatively limited in size and weight, such as scallops, inlet distributors, outlet collectors and distributor trays. Others are of considerable size and weight, such as cartridges, which can reach lengths of 30 metres and can weigh more than 100 tons.

Cartridges are stainless steel non-pressure vessels in which the individual internals are installed before the cartridge is shipped. Once at the plant, the cartridges, complete with all the internals, are inserted into flanged reactors.

Other reactor internals include outer baskets and inner baskets or special gratings, distributors and heat exchangers.

QUALITY CONTROLS

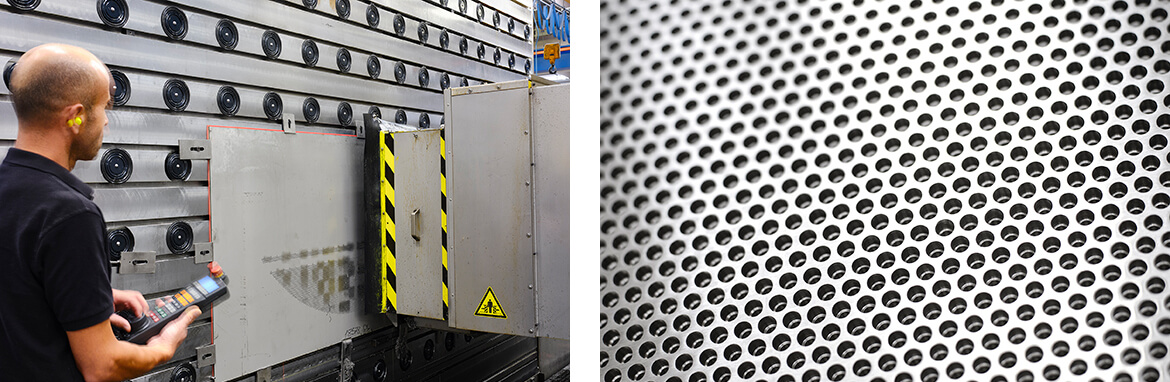

Costacurta has been maintaining an ISO 9001 certified quality system for over 25 years that entails strict quality control procedures throughout the entire production cycle, including:

- positive material identification using portable analysers based on X-ray fluorescence

- dimensional controls of the componentswith different instruments also including laser tracking

- non-destructive controls of the PT, VT, UT and RX welding carried out by ASME IX certified personnel.

DISCOVER THE OTHER DISTINCTIVE ELEMENTS OF REACTOR INTERNALS