At its plant, Costacurta manufactures and is able to handle a wide range of Reactor Internals of different sizes and weights, ranging from a few tons to more than 100 tons.

Do you have a specific request?

Contact us nowCostacurta produces Reactor Internals consisting of components of relatively limited size and weight, such as ‘scallops’, ‘inlet distributors’, ‘outlet collectors’ and ‘distributor trays’ but also Reactor Internals of a large size and weight such as ‘cartridges’ that can reach lengths of 30 metres and a weight of more than 100 tons.

The ‘cartridges’ are stainless steel containers in which all the individual components of the Reactor Internals are installed before being shipped. Once at the plant, the ‘cartridges’, complete with all the Internals, are inserted in a flanged reactor. The main components of the Reactor Internals can be: ‘outer baskets’ and ‘inner baskets’ or ‘special gratings’ and ‘distributors’ and heat exchangers.

Continuous improvement of the manufacturing process

Costacurta invests in machinery and equipment with the aim of improving product quality and productivity. It now has a wide range of machines and equipment that enable a high level of automation. Costacurta has also invested and continues to invest in the expansion of the production plant areas and in increasing the lifting and handling capacity to be able to manufacture large, heavy Reactor Internals.

One of Costacurta’s main strengths is its capability to manage the entire production process in-house: from the construction of the filtering elements (perforated plates, wedge wire screens, wire cloths and meshes) to the manufacture of finished components, supported by cutting-edge technologies and highly skilled personnel.

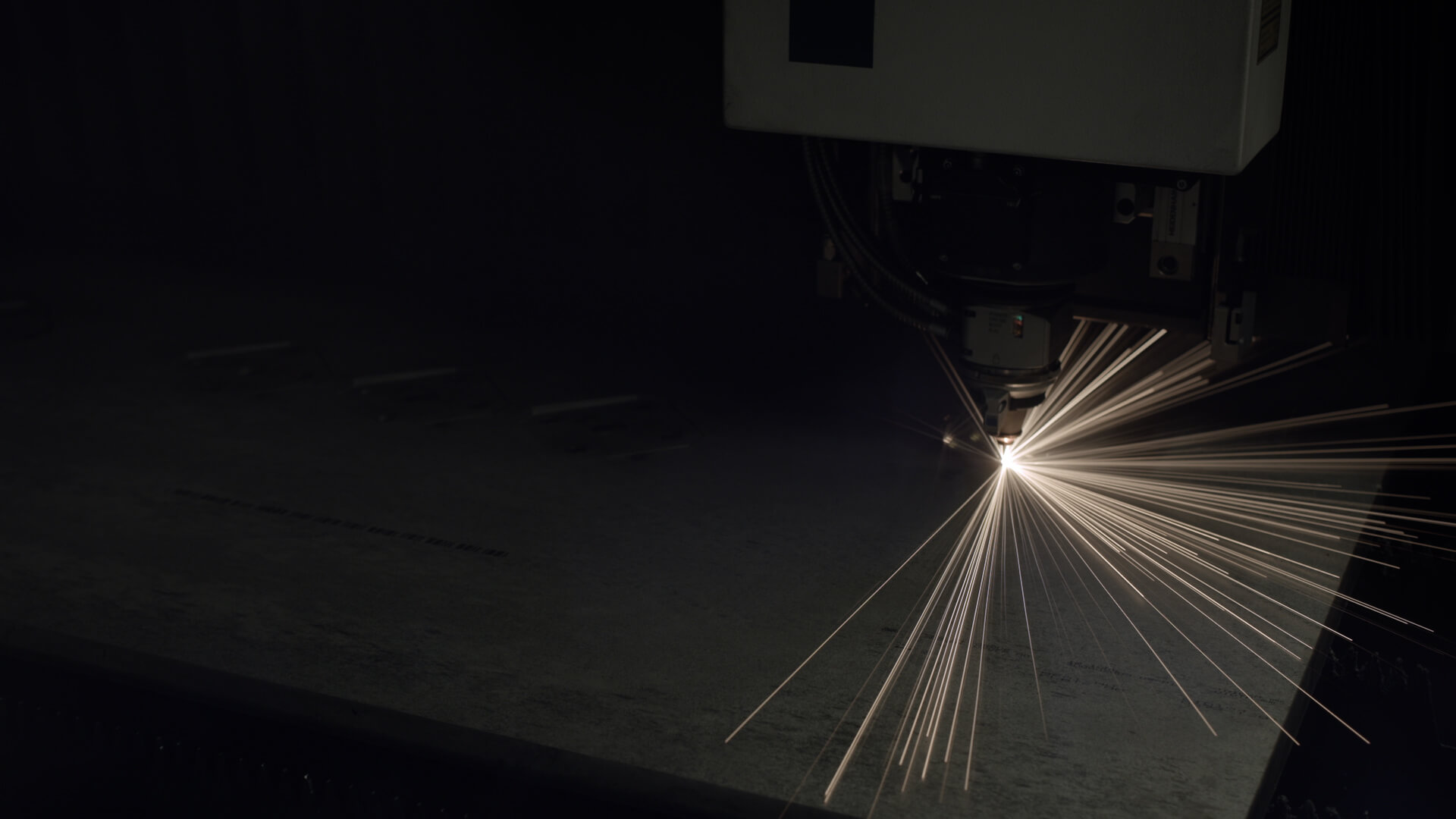

CUTTING OF PLATES AND FILTERING ELEMENTS

- Laser

- Plasma

- Water-jet.

WELDING

- ASME IX certified welders

- Automatic and robotic welding

- Orbital welding

- Submerged arc welding.

HANDLING AND ASSEMBLY

Costacurta’s facilities have bridge cranes and special forklift trucks to handle components weighing up to 80 tons, a seven meter deep pit and a 30 meter high tower for the vertical assembly of Radial Flow Reactor Internals. The area in front of the tower also enables the addition of two mobile cranes to handle components weighing up to 100 tons.

QUALITY CONTROLS

Costacurta has had an ISO 9001 certified quality system for 25 years that entails strict quality control procedures throughout the entire production cycle, including:

- dimensional controls and identification of the raw materials using portable analysers based on X-ray fluorescence

- dimensional controls of the components also using laser equipment

- non-destructive controls of the PT, VT, UT and RX welding carried out by ASME IX certified personnel.

DISCOVER THE OTHER REACTOR INTERNALS DISTINCTIVE FEATURES